Ingegneria Strutturale Superiore e Durata

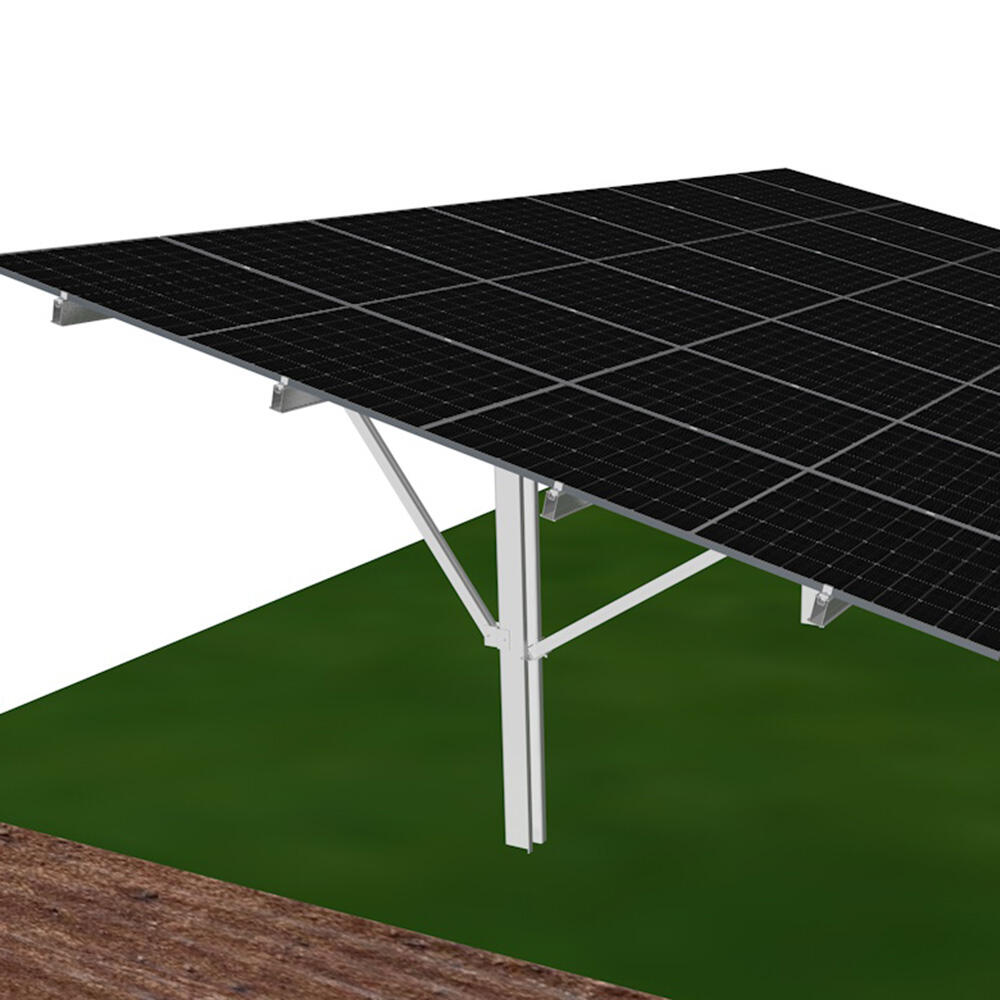

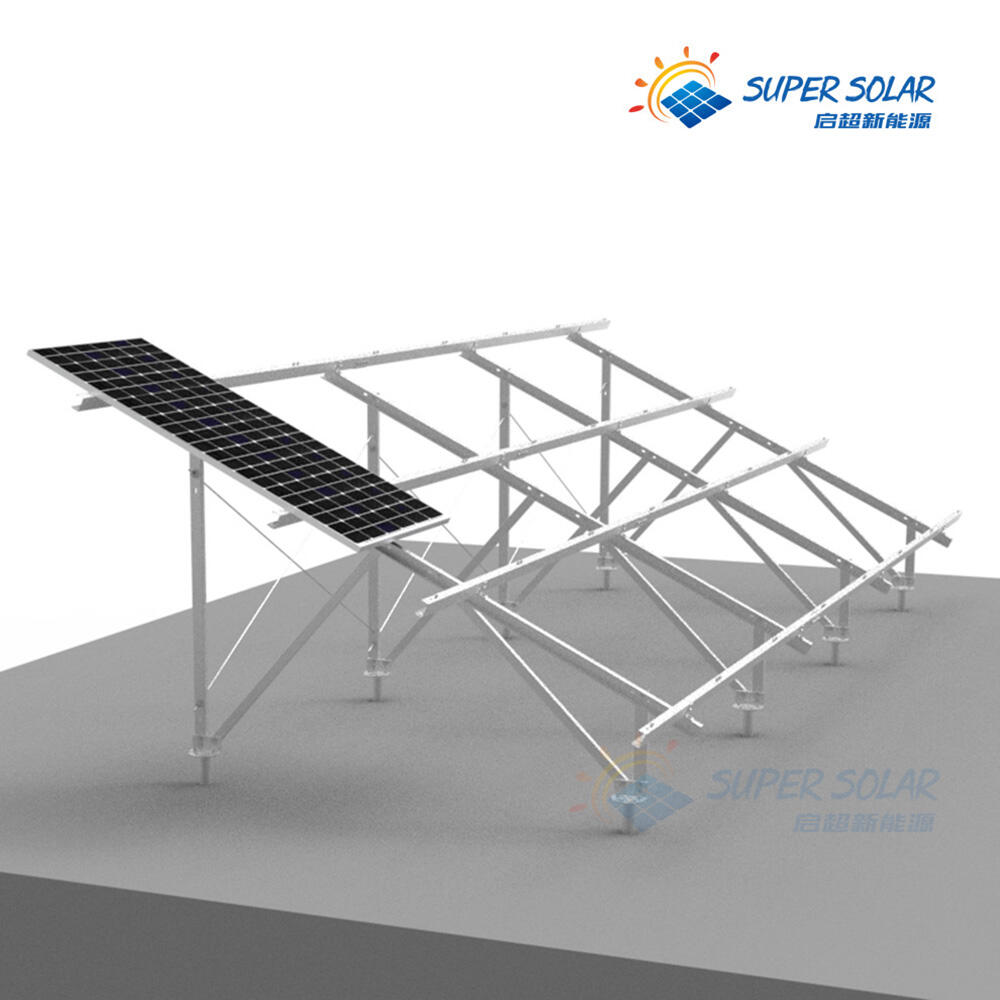

I sistemi commerciali per impianti fotovoltaici su palafitta sono caratterizzati da un'eccezionale ingegneria strutturale che garantisce prestazioni affidabili anche in condizioni ambientali estreme, offrendo decenni di funzionamento senza necessità di manutenzione. Il sistema di fondazione utilizza pali infissi in profondità o plinti in calcestruzzo armato, che assicurano una stabilità assoluta, ancorando l'intero impianto contro venti di forza uragano, attività sismica ed eventi meteorologici estremi. L'analisi avanzata agli elementi finiti guida il processo di progettazione strutturale, ottimizzando l'uso dei materiali e rispettando o superando i codici edilizi locali e gli standard di sicurezza del settore. La struttura è realizzata con componenti in acciaio zincato o in alluminio marino, resistenti alla corrosione, alla degradazione causata dai raggi UV e agli effetti del ciclaggio termico, che potrebbero compromettere sistemi di fissaggio meno performanti nel tempo. Ogni progetto di impianto fotovoltaico commerciale su palafitta è certificato da ingegneri qualificati per specifiche aree geografiche, tenendo conto dei carichi eolici locali, dell'accumulo di neve, dei fattori sismici e delle condizioni del terreno che influiscono sui requisiti strutturali. La costruzione robusta del sistema di montaggio supporta non solo il peso dei pannelli, ma anche il carico derivante dalla presenza di personale addetto alla manutenzione, consentendo un accesso sicuro per le operazioni di pulizia e assistenza durante tutta la vita operativa del sistema. Processi di controllo qualità garantiscono che tutti i componenti strutturali soddisfino rigorose tolleranze di produzione e specifiche dei materiali prima di lasciare la fabbrica. Le procedure di installazione seguono specifiche ingegneristiche dettagliate che assicurano un montaggio corretto e l'integrità strutturale dell'intera configurazione dell'impianto. La progettazione del sistema incorpora giunti di dilatazione termica e connessioni flessibili, in grado di compensare le variazioni di temperatura senza generare concentrazioni di stress che potrebbero portare a rotture per fatica. I sistemi di protezione contro i fulmini sono integrati nel telaio strutturale, fornendo una protezione completa contro le sovratensioni, salvaguardando sia il sistema di montaggio che le apparecchiature elettriche collegate. L'ingegnerizzazione dell'impianto fotovoltaico commerciale su palafitta tiene conto di scenari di carico progressivo, garantendo che la struttura mantenga la propria integrità anche in caso di concentrazioni di stress impreviste su singoli componenti. Laboratori indipendenti di prova ne convalidano le prestazioni strutturali attraverso rigorosi test di carico che simulano decenni di esposizione ambientale in tempi accelerati. La costruzione modulare del sistema facilita il controllo qualità, consentendo il preassemblaggio e il collaudo in fabbrica dei collegamenti strutturali critici prima dell'installazione in campo. La copertura della garanzia riflette la fiducia del produttore nella durabilità strutturale, spesso estendendosi a venticinque anni o più per i componenti strutturali principali. Il pacchetto documentale ingegneristico comprende specifiche complete, disegni di installazione e procedure di manutenzione, garantendo una corretta gestione del sistema per tutta la sua vita operativa.