Solar Mounting Systems

Contact Us

- Building A06, Jimei Software Park, Xiamen, China

- +86-592-6683155

- [email protected]

Aluminum Carport For Home

Aluminum Carport For Business

Steel Carport For Business

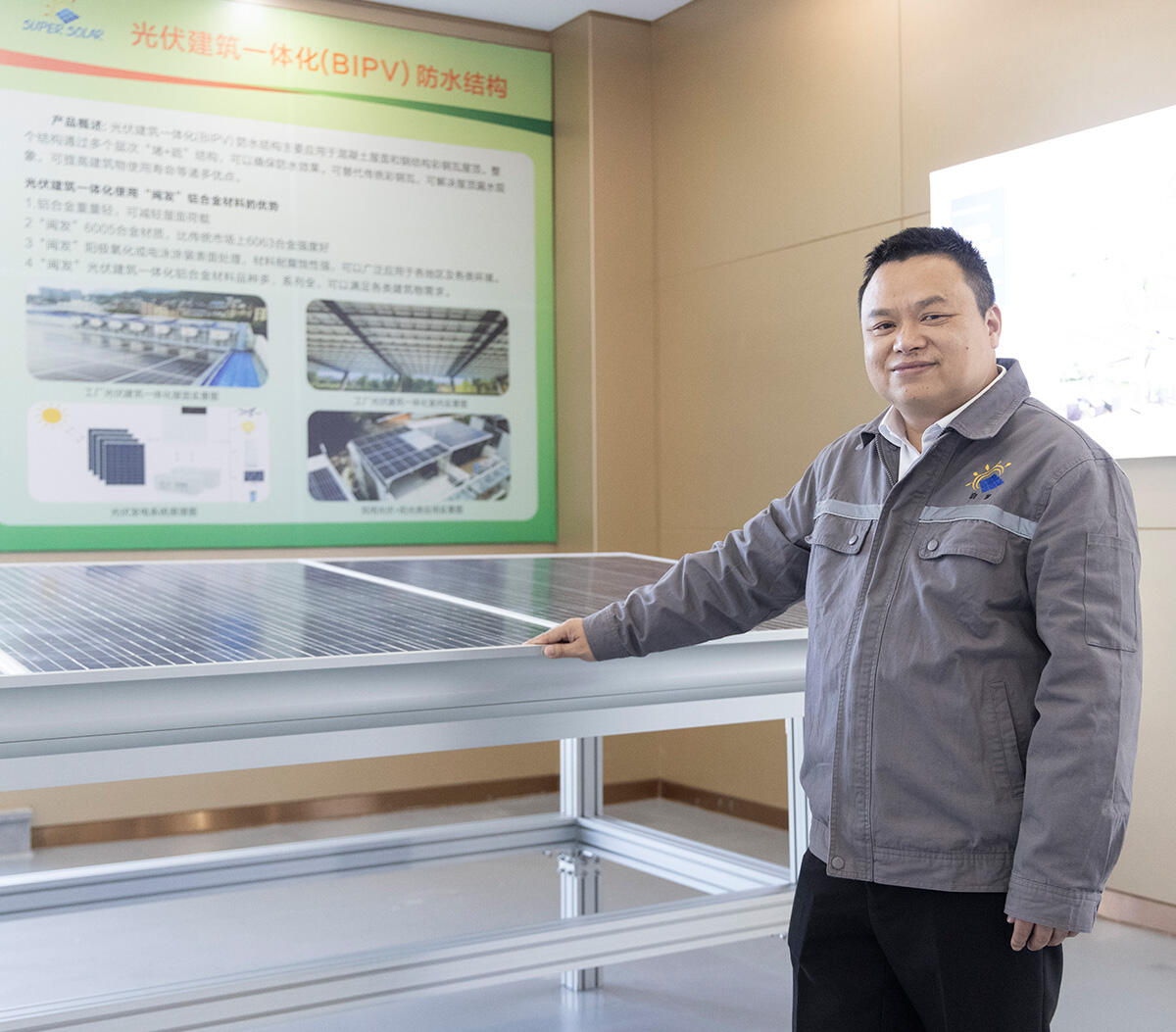

Waterproof Solution

Railing Adjustable Triangle Bracket

Railing Adjustable Pillar Bracket

Universal 3-Way Adjustable Bracket

On grid solar power system

Off grid solar power system

Hybrid solar power system

PV installation accessories (rails, brackets), electrical components (MC4 connectors, cables), and various protection devices (surge protectors, fuses).

Ground solar power station

Rooftop solar power station

Years of industry experience

Capacity(MW)

Working with top universities and research institutions to enhance our technology through practical projects

We hold numerous patents and international certifications (ISO 9001, CE, UL), ensuring unique technology and the highest quality standards.

We offer customized professional photovoltaic solutions for roof, ground, carport, balcony and more.

All brackets and systems, made from high-grade materials and rigorously tested, ensure long-term durability.

We offer solar panels, brackets, battery, controllers, inverters & solar power system.

Our designs maximize efficiency and ease of installation, featuring adjustable angles and modular components for optimal performance.

Frequently asked questions amid energy shift, Super Solar innovates solar PV. Founded in 2006 on aluminum mounts, renowned for quality. In 2017, expanded to R&D, production, sales. Committed to clean energy, empowering homes & biz for a greener future.

We offer a variety of mounting systems, including ground-mounted, roof-mounted, and carport solutions. Our mounting structures are made from high-quality aluminum and are designed for easy installation and durability in diverse environmental conditions.

Absolutely. We offer tailored PV system design services to help our customers optimize their installations. Our engineering team works closely with you to ensure that the system meets your specific needs and local regulations.

Super Solar adheres to strict quality control standards at every stage of production. Our products are certified by international standards such as IEC, CE, and TUV, ensuring reliable performance and safety.

Yes, we have extensive experience in exporting our products globally. We handle all aspects of international shipping, including packaging, documentation, and logistics, to ensure a smooth delivery process.