produttore di supporti inclinati per pannelli solari

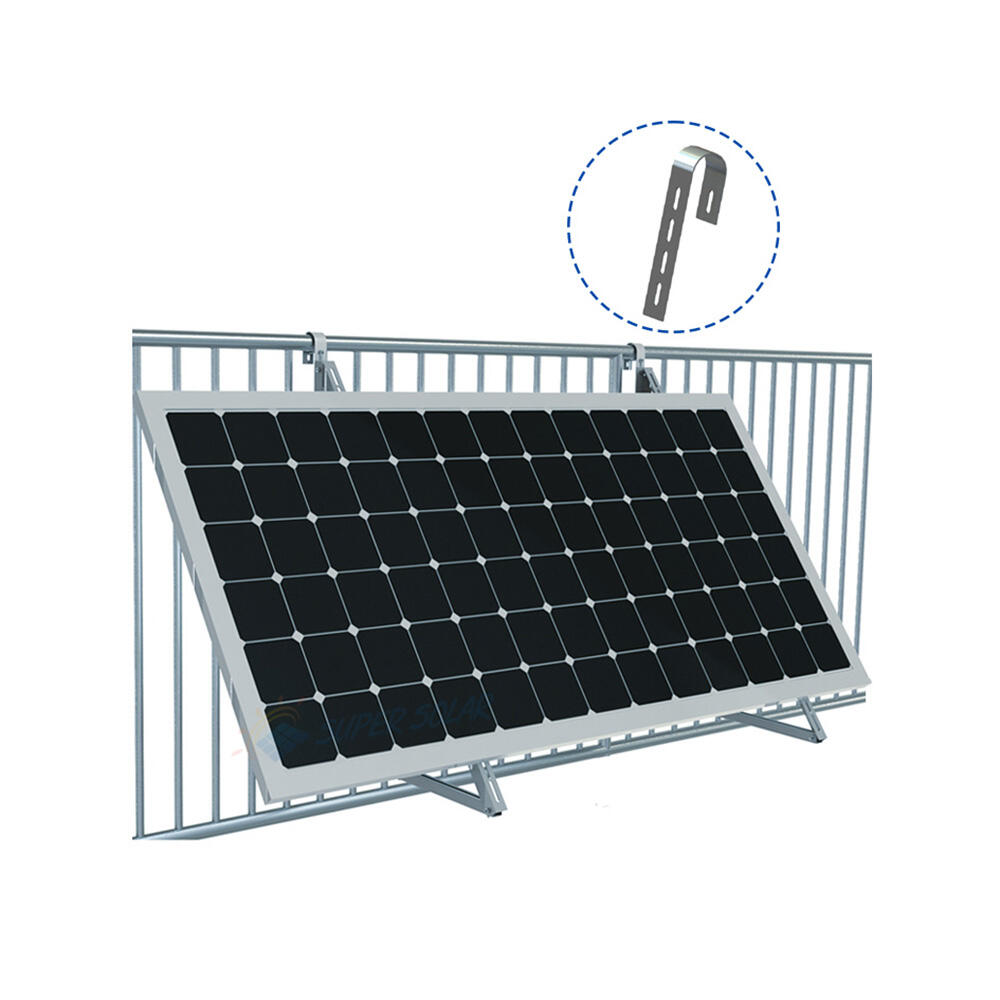

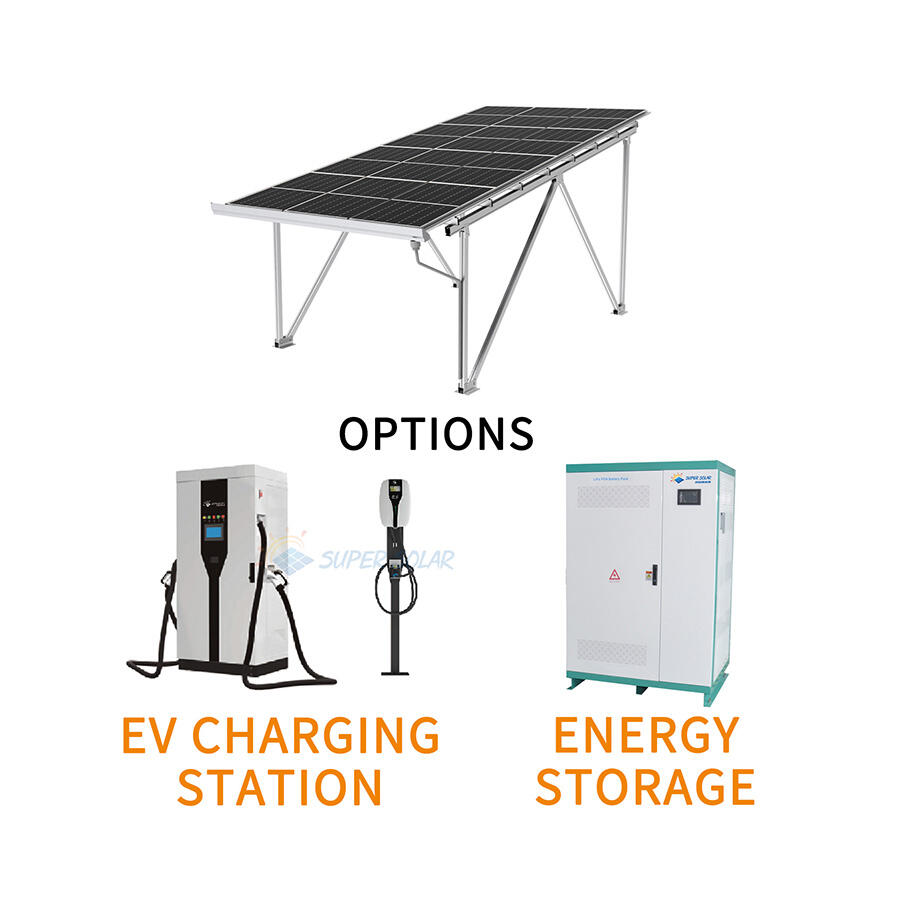

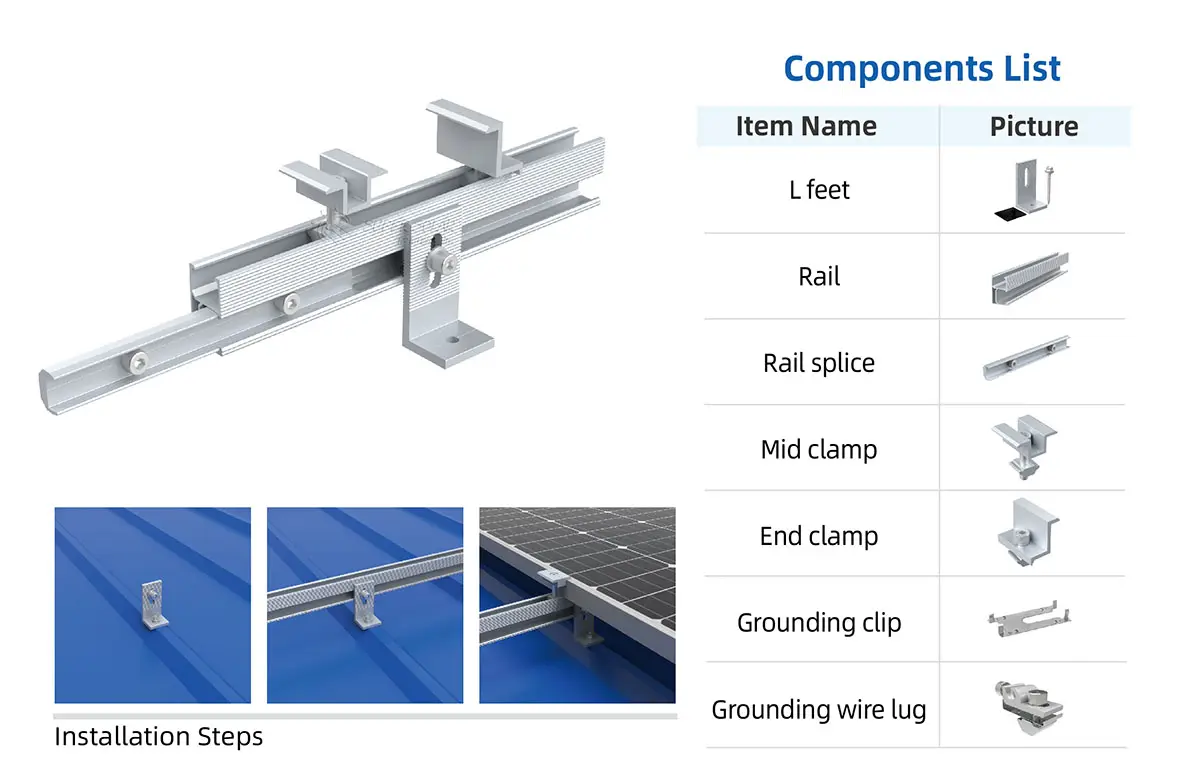

Una fabbrica di supporti inclinabili per pannelli solari rappresenta un'azienda specializzata nella produzione di soluzioni di montaggio progettate con precisione per ottimizzare il posizionamento dei pannelli solari al fine di massimizzare la cattura dell'energia. Queste fabbriche si concentrano esclusivamente sulla creazione di sistemi di supporto regolabili che consentono agli impianti fotovoltaici di raggiungere angoli ottimali durante diverse stagioni e in diverse ubicazioni geografiche. La funzione principale di una fabbrica di supporti inclinabili per pannelli solari consiste nel progettare, produrre e distribuire diversi tipi di meccanismi inclinabili in grado di adattarsi a varie dimensioni, pesi dei pannelli e ambienti di installazione. La fabbrica produce supporti capaci di resistere a condizioni meteorologiche estreme, inclusi forti venti, carichi elevati di neve e ambienti corrosivi, mantenendo l'integrità strutturale per decenni di funzionamento. Le caratteristiche tecnologiche delle moderne operazioni di fabbrica di supporti inclinabili per pannelli solari includono la lavorazione avanzata di leghe di alluminio, capacità di lavorazione dell'acciaio inossidabile e attrezzature di precisione per la fresatura, che garantiscono una qualità costante in tutti i prodotti. Queste strutture utilizzano sistemi di progettazione assistita da computer per creare soluzioni personalizzate in base a specifiche esigenze progettuali, mentre linee di produzione automatizzate assicurano standard uniformi di fabbricazione. La fabbrica integra rigorosi protocolli di test, tra cui prove di carico, valutazioni della resistenza alla corrosione e verifiche di durata che simulano condizioni reali. Le applicazioni dei prodotti realizzati in una fabbrica di supporti inclinabili per pannelli solari comprendono installazioni residenziali su tetti, progetti su edifici commerciali, grandi impianti fotovoltaici su scala industriale e applicazioni specializzate come sistemi solari galleggianti. I supporti si adattano a diverse superfici di montaggio, tra cui fondazioni in calcestruzzo, tetti metallici, coppi in asfalto e strutture montate a terra. Le fabbriche più avanzate producono anche componenti di sistemi di inseguimento (tracking) che regolano automaticamente l'inclinazione dei pannelli durante il giorno seguendo il percorso del sole, massimizzando così l'efficienza produttiva e il ritorno sull'investimento per progetti solari di ogni dimensione.