How to Choose the Right Solar Ground Mounting Foundation: Concrete, Ground Screw, or Pile-Driven System?

When designing a solar ground mounting project, the foundation type is one of the most critical decisions to make. A well-selected foundation ensures structural stability, installation efficiency, and long-term reliability.

In today’s solar market, Concrete Foundations, Ground Screws, and Pile-Driven (Ramming) Systems are the three most common solutions. Each has its own advantages depending on soil conditions, project scale, and local construction environments.

1️⃣ Concrete Foundation — The Traditional and Reliable Choice

Installation Method

Concrete foundations require excavation of pits or trenches, setting up rebar cages and formwork, then pouring concrete blocks or pillars. After curing (usually 7–14 days), solar mounting structures are fixed with anchor bolts.

Advantages

- Excellent stability and durability; ideal for long-term installations (25–30 years).

- Works on all kinds of ground, including rocky and hard terrain.

- Widely accepted by traditional EPC contractors and government projects.

- High bearing capacity and strong wind resistance.

Disadvantages

- Time-consuming installation and curing period.

- Requires heavy labor and civil work.

- Difficult to dismantle or relocate; not environmentally friendly.

- Increases overall project time and cost.

Best for: Large utility-scale solar plants on rocky ground or regions requiring high load-bearing capacity.

2️⃣ Ground Screw Foundation — Fast, Flexible, and Eco-Friendly

Installation Method

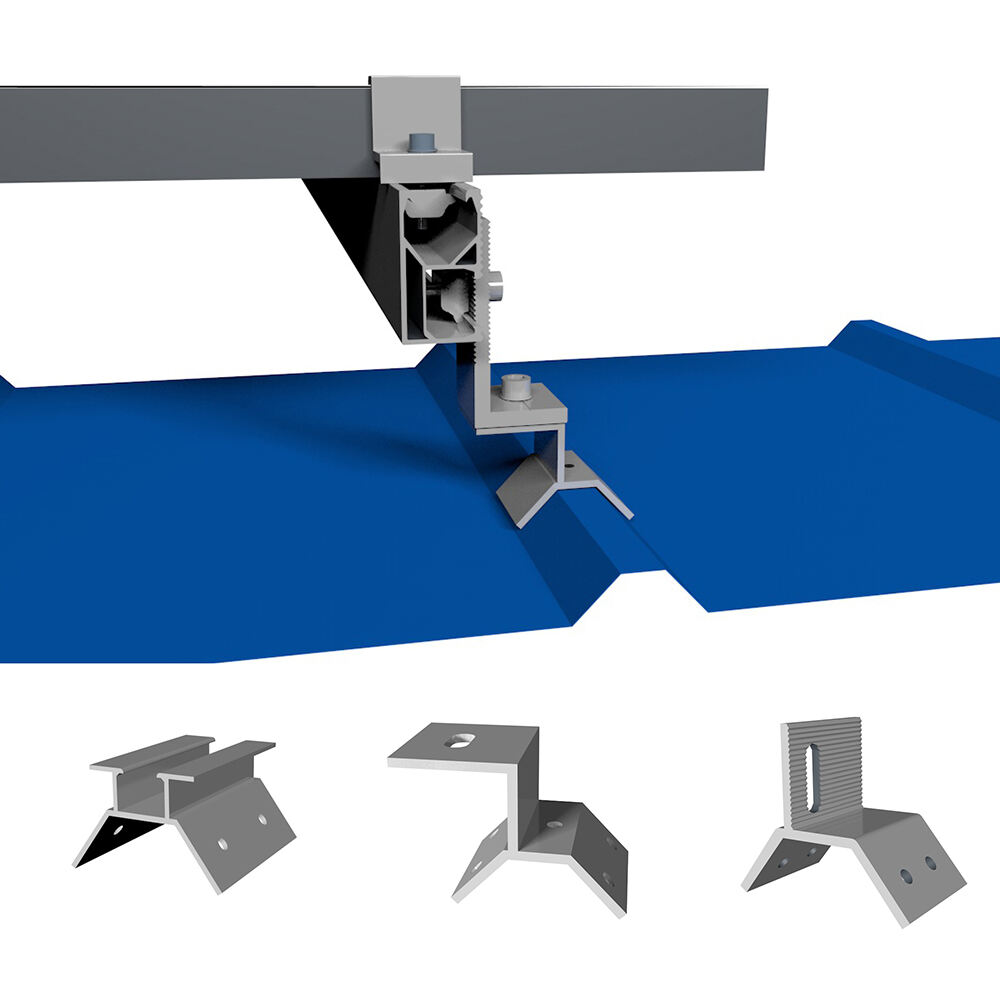

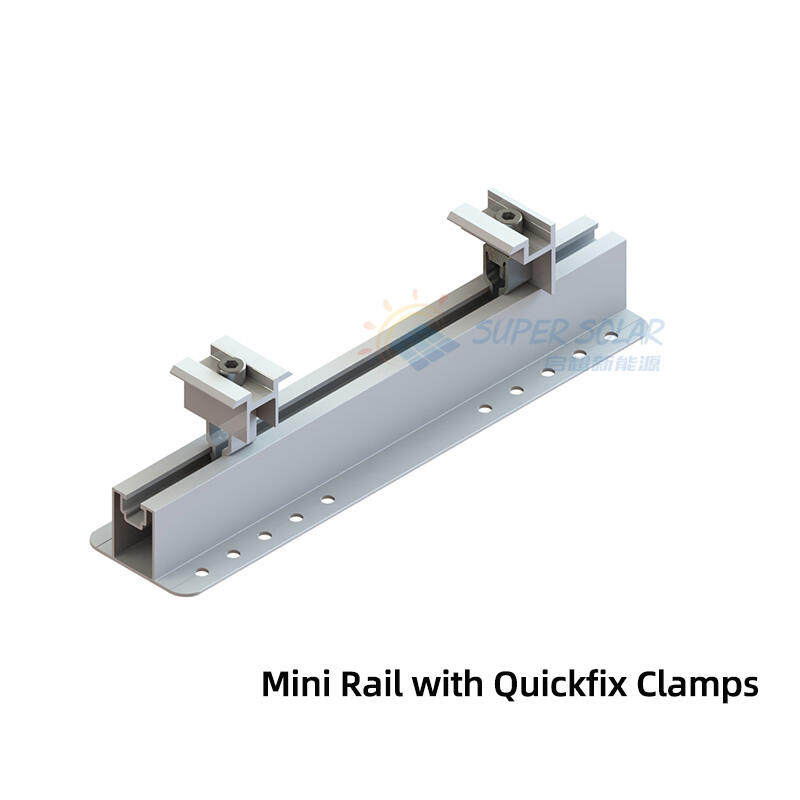

Ground screws are steel anchors with spiral blades that are drilled directly into the soil using a hydraulic screw-driving machine. Once installed, aluminum or steel mounting structures are attached to the screw heads.

Advantages

- No excavation or concrete needed — faster installation (up to 60% time savings).

- Minimal environmental impact; land can be restored easily.

- Suitable for a wide range of soils — sandy, loamy, or clay — and uneven terrain.

- Reusable and relocatable, ideal for temporary or semi-permanent projects.

- Cost-effective when labor and construction time are considered.

Disadvantages

- Not suitable for rocky or extremely hard ground.

- Requires professional machinery and skilled operators.

- Installation accuracy must be well controlled.

Best for: Medium and small ground solar systems, agricultural PV projects, distributed generation systems, and eco-friendly developments in Europe, Australia, and Japan.

Market Trend

The use of ground screw foundations is rapidly growing worldwide, especially in regions with high labor costs and strict environmental standards. It is becoming one of the mainstream solutions for modern PV installations.

3️⃣ Pile-Driven (Ramming) Ground Mounting — Strong and Efficient for Large Projects

Installation Method

Steel piles (usually H-beams or C-sections) are driven vertically into the soil by a hydraulic piling machine without any concrete. The mounting rails are then fixed directly on the top of the piles.

Advantages

- Very fast installation — hundreds of piles can be driven in a single day.

- Excellent structural strength and pull-out resistance.

- Fully mechanized process with consistent quality.

- No need for concrete, reducing logistics and material costs.

- Ideal for large-scale, flat, open areas.

Disadvantages

- Requires heavy piling equipment (high initial investment).

- Not suitable for rocky terrain or underground obstacles.

- Generates noise and vibration during construction.

- Hard to remove completely after the project ends.

Best for: Large-scale solar farms (above 1 MW), flat desert or farmland, projects with tight construction schedules.

⚖️ Comparison Overview

| Feature | Concrete Foundation | Ground Screw | Pile-Driven (Ramming) |

|---|---|---|---|

| Construction Speed | Slow (needs curing) | Very Fast | Very Fast |

| Ground Adaptability | All terrains, including rock | Soft to medium soil | Medium soil, no rock |

| Equipment Needed | Mixer, rebar, formwork | Screw-driving machine | Hydraulic pile driver |

| Environmental Impact | High (concrete waste) | Low | Medium |

| Reusability | No | Yes | Limited |

| Labor Cost | High | Low | Medium |

| Durability | Excellent | Excellent | Excellent |

| Overall Cost-Efficiency | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

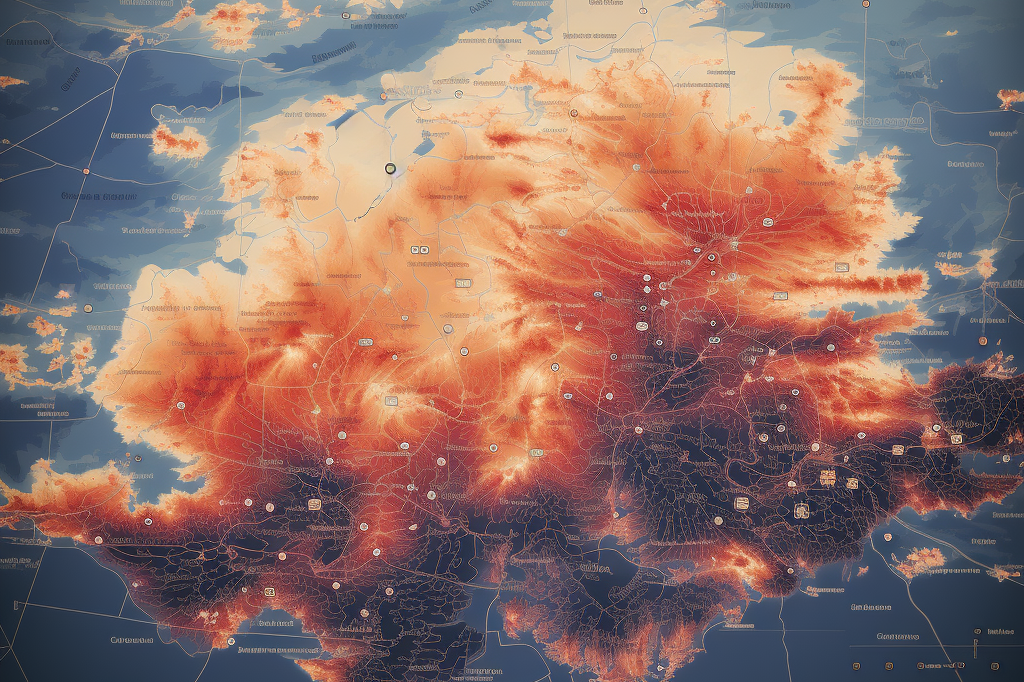

| Common Markets | Asia, Africa | Europe, Australia, Japan | USA, India, Middle East |

🧭 Which Solar Ground Mounting Foundation Is Right for You?

| Project Type | Recommended Solution | Reason |

|---|---|---|

| Medium to small installations / short project time / eco-friendly design | Ground Screw | Fast installation, flexible, reusable |

| Large utility-scale solar farms on flat land | Pile-Driven (Ramming) | Mechanized, efficient, cost-effective |

| Rocky soil or permanent installations | Concrete Foundation | Maximum stability and long lifespan |

🌞 Super Solar Recommendation

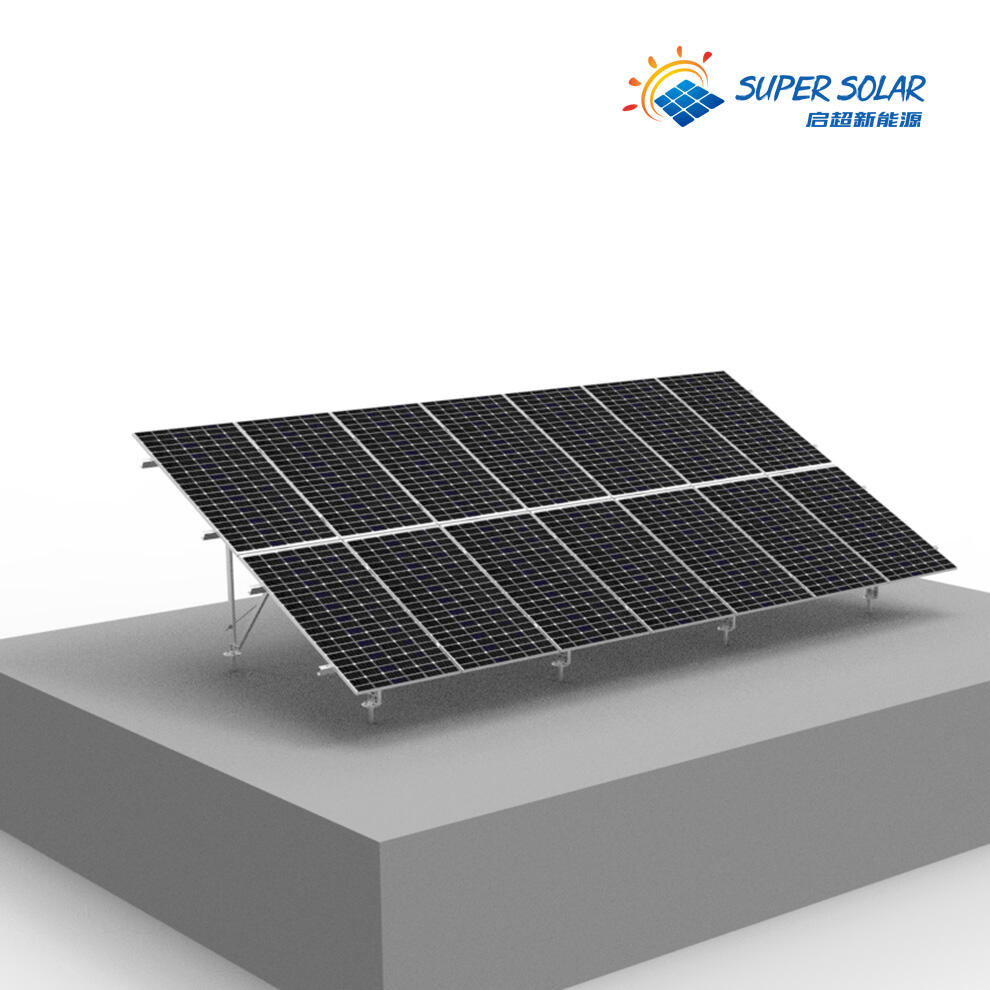

At Super Solar, we provide complete solar ground mounting systems designed for all three foundation types:

- Aluminum and steel structures compatible with ground screw, pile-driven, and concrete foundations.

- Custom design and engineering support based on your local soil conditions and project scale.

- Fast production, global delivery, and technical assistance for installers and EPCs.

Whether your project demands speed, flexibility, or long-term durability, Super Solar has the right solution to meet your needs.

Hot News

Hot News