Превосходная конструкционная инженерия и распределение нагрузки

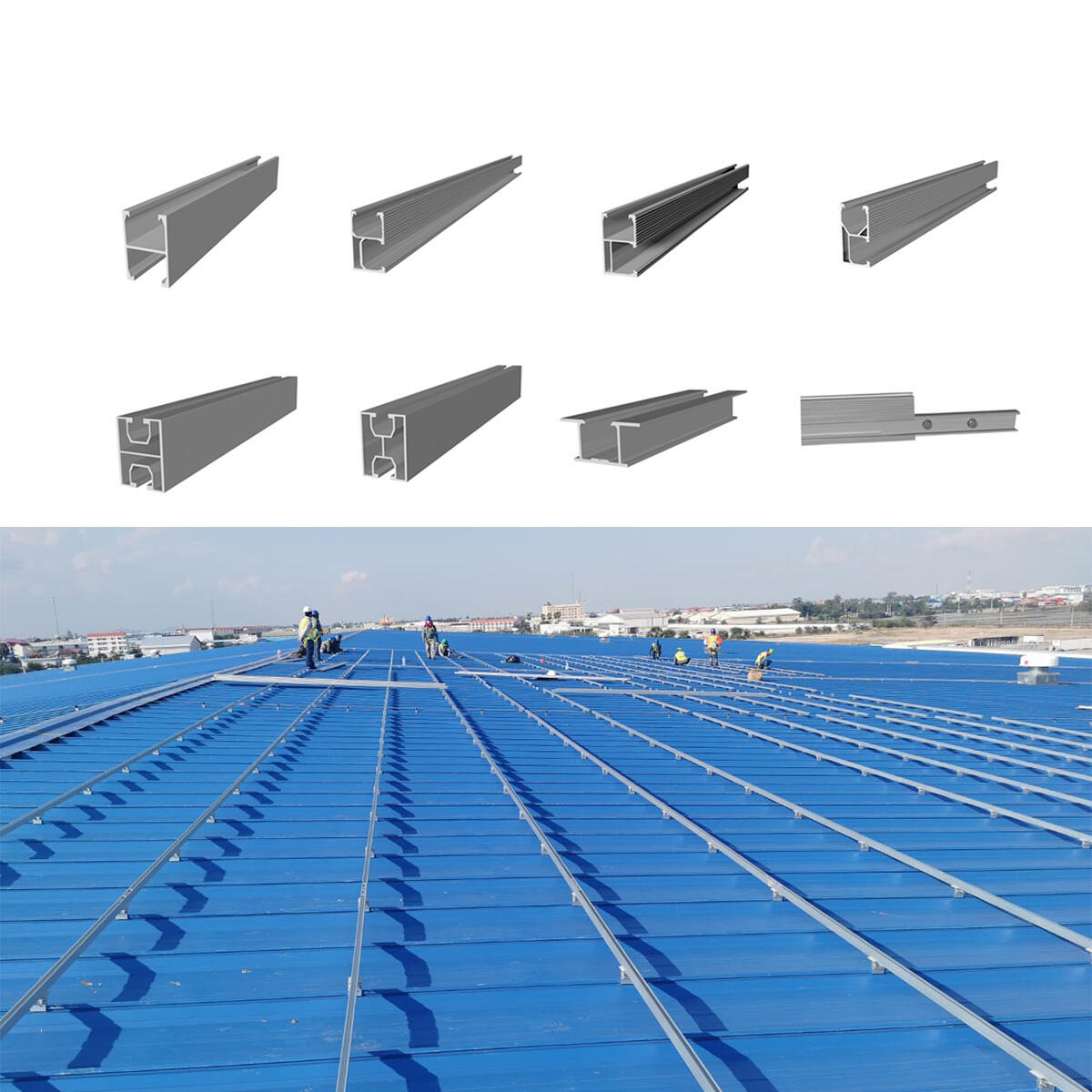

Высокое качество конструкций систем крепления солнечных панелей на крыше отличает их от стандартных аналогов благодаря сложным механизмам распределения нагрузки, которые защищают как солнечные установки, так и underlying конструкции крыши. Эти передовые системы крепления используют спроектированные направляющие, охватывающие несколько точек крепления на крыше, создавая сеть распределённой нагрузки, которая предотвращает сосредоточенное напряжение на отдельных элементах кровли. Система направляющих действует как конструкционный мост, перераспределяя суммарный вес солнечных панелей, крепёжных элементов и внешних нагрузок на большую площадь крыши, а не концентрируя усилия в изолированных точках. Такой распределённый подход значительно снижает риск повреждения крыши, проникновения воды и конструкционных разрушений, которые могут возникнуть при использовании менее качественных решений для крепления. Премиальные системы крепления включают точные инженерные расчёты, учитывающие местные скорости ветра, снеговые нагрузки, сейсмическую активность и строительные нормы, чтобы обеспечить достаточный запас прочности при всех ожидаемых условиях. Конструкционные компоненты проходят строгие испытания, включая испытания на вырыв, оценку устойчивости к отрыву и циклические испытания на усталость, чтобы подтвердить работоспособность в экстремальных условиях. Выбор передовых материалов играет ключевую роль в конструкционной надёжности: высококачественные алюминиевые сплавы обеспечивают оптимальное соотношение прочности и массы, одновременно устойчивы к коррозии в морских и промышленных условиях. Целостность конструкции системы крепления распространяется и на детали соединений, где прецизионно обработанные интерфейсы обеспечивают надёжное крепление между направляющими, зажимами и панелями без создания концентраторов напряжений, которые могут привести к преждевременному выходу из строя. Качественные системы крепления также предусматривают компенсацию теплового расширения за счёт продуманных соединительных узлов, которые позволяют перемещение материалов при колебаниях температуры, сохраняя при этом конструкционную целостность. Такое управление тепловыми воздействиями предотвращает возникновение внутренних напряжений, способных повредить панели или компоненты крепления. Результатом является система крепления, сохраняющая свои конструкционные характеристики на протяжении десятилетий эксплуатации и защищающая значительные инвестиции в солнечные панели и кровельные системы. Владельцы недвижимости получают дополнительное спокойствие, зная, что их солнечная установка использует технологию крепления, превосходящую отраслевые стандарты по конструкционной надёжности и безопасности.