solar roof mounting factory

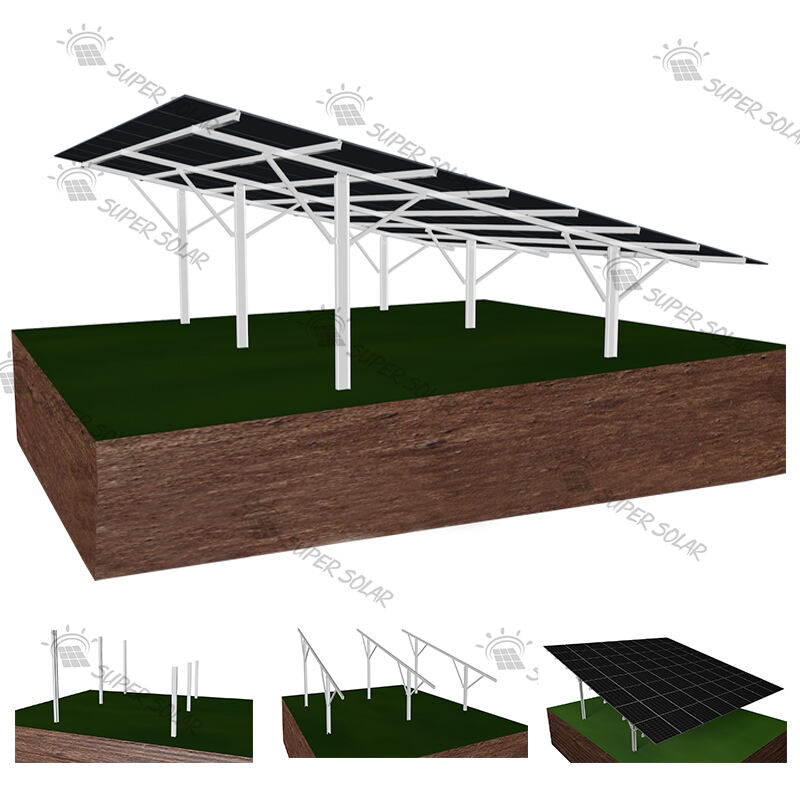

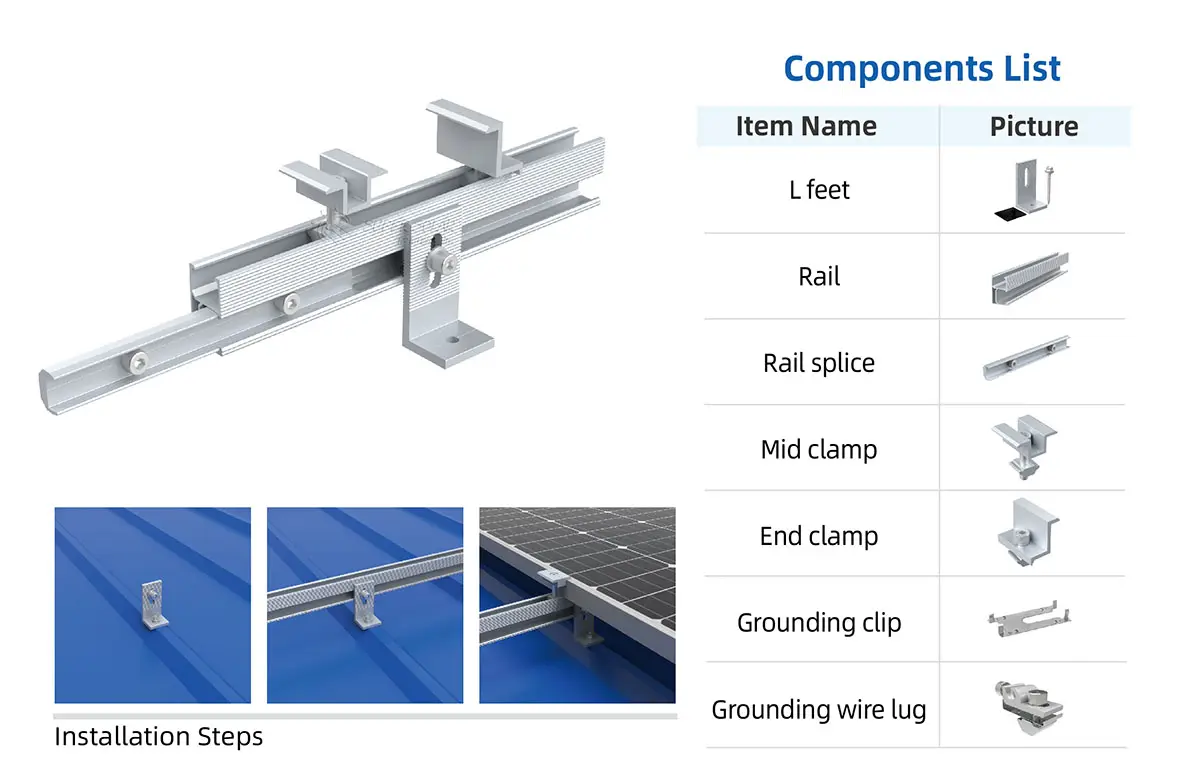

A solar roof mounting factory serves as a specialized manufacturing facility dedicated to producing high-quality mounting systems that secure solar panels onto residential and commercial rooftops. These sophisticated facilities combine advanced engineering principles with modern production techniques to create durable, weather-resistant mounting solutions that ensure optimal solar panel performance across diverse architectural structures. The solar roof mounting factory operates through multiple interconnected production lines, each designed to handle specific components such as rails, clamps, brackets, and fastening hardware. These manufacturing centers utilize precision machining equipment, automated welding systems, and quality control stations to maintain consistent product standards throughout the production process. The technological infrastructure within a solar roof mounting factory incorporates computer-aided design systems, material testing laboratories, and environmental simulation chambers that validate product durability under extreme weather conditions. Manufacturing processes include aluminum extrusion for lightweight yet strong rail systems, stainless steel fabrication for corrosion-resistant components, and specialized coating applications that enhance longevity in harsh outdoor environments. The solar roof mounting factory typically maintains extensive inventory management systems that coordinate raw material procurement, work-in-progress tracking, and finished goods distribution to meet fluctuating market demands. Quality assurance protocols within these facilities encompass dimensional accuracy verification, load-bearing capacity testing, and compatibility assessments with various solar panel manufacturers. Applications for products manufactured in a solar roof mounting factory span residential installations on single-family homes, commercial deployments on office buildings and warehouses, and utility-scale projects requiring specialized mounting solutions. These facilities also produce customized mounting systems for unique architectural challenges, including curved rooflines, standing seam metal roofs, and tile installations that require specialized attachment methods.