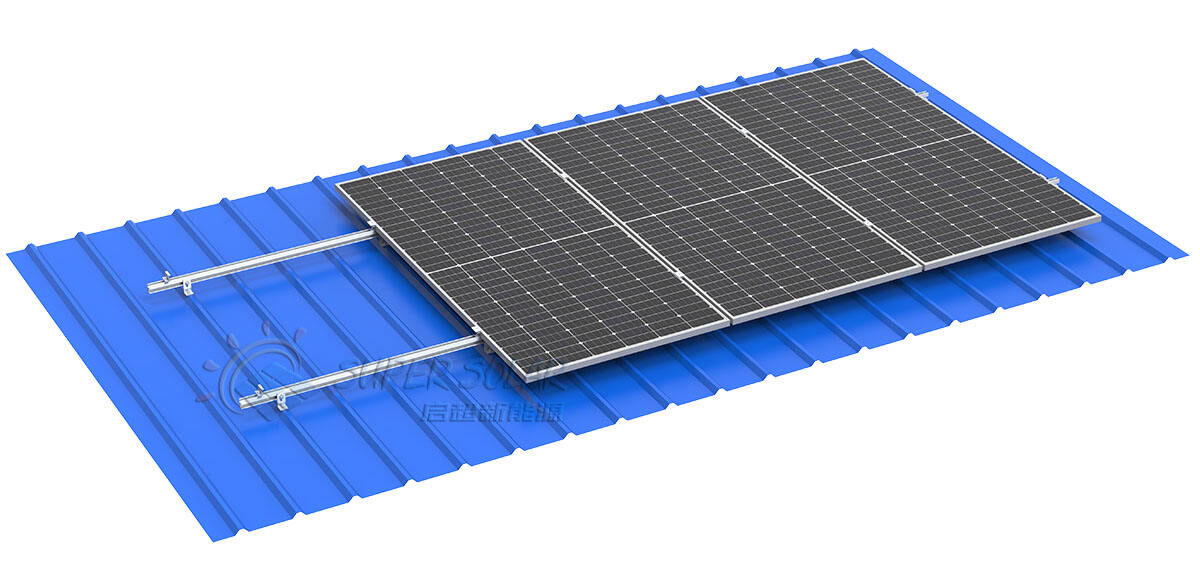

Why metal roof projects are growing

The rise of the metal roof project is no accident. More property owners and businesses are turning to this type of roofing for its durability, aesthetics, and ability to support solar energy systems. Unlike traditional shingles, a metal roof project provides strength and longevity, often lasting over 40 years. It is resistant to fire, wind, and moisture, making it a reliable choice for diverse climates. Installers appreciate that a metal roof project combines style with practical benefits, while distributors see increasing demand in both residential and commercial sectors. With the growing focus on renewable energy, this trend shows no sign of slowing.

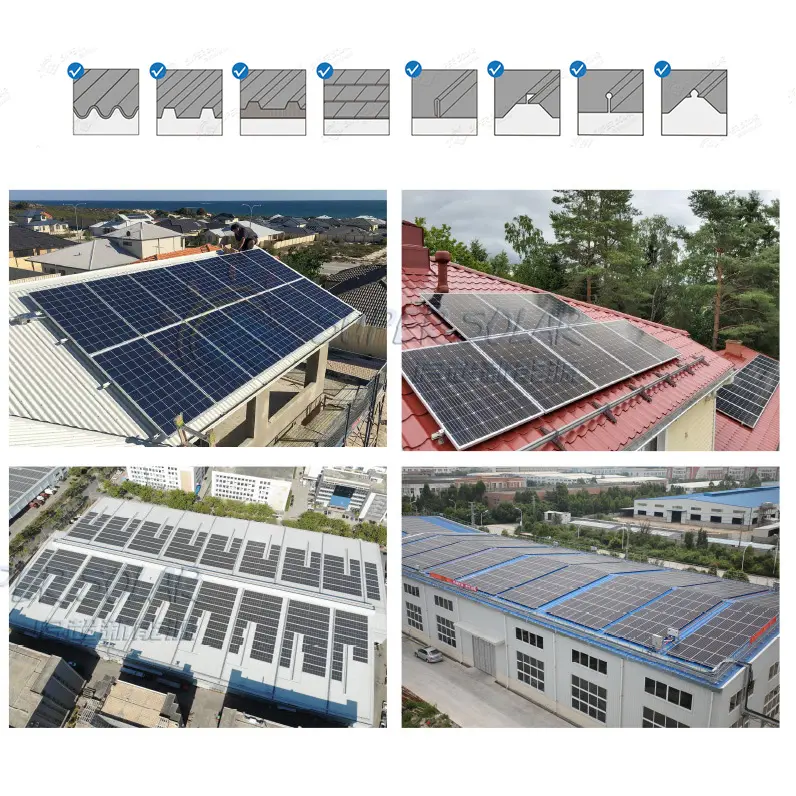

Wide compatibility with roof types

Adaptability across different profiles

One of the main reasons L feet are preferred for a metal roof project is their compatibility with different roof profiles. Standing seam roofs, corrugated panels, and trapezoidal structures all present unique challenges. L feet are designed to adapt to these variations, reducing the need for multiple product lines. Installers no longer need to worry about whether their mounting solution will fit a particular project. This versatility simplifies logistics and improves efficiency across the supply chain.

Why versatility matters for installers

Why is versatility such an advantage in the metal roof project industry? Each project comes with unique site conditions, from slope angles to local building codes. Using a universal mounting solution allows installers to handle projects of varying complexity without sacrificing quality. This flexibility also gives distributors confidence that the products they stock can meet wide-ranging needs, ensuring consistent demand and satisfied customers.

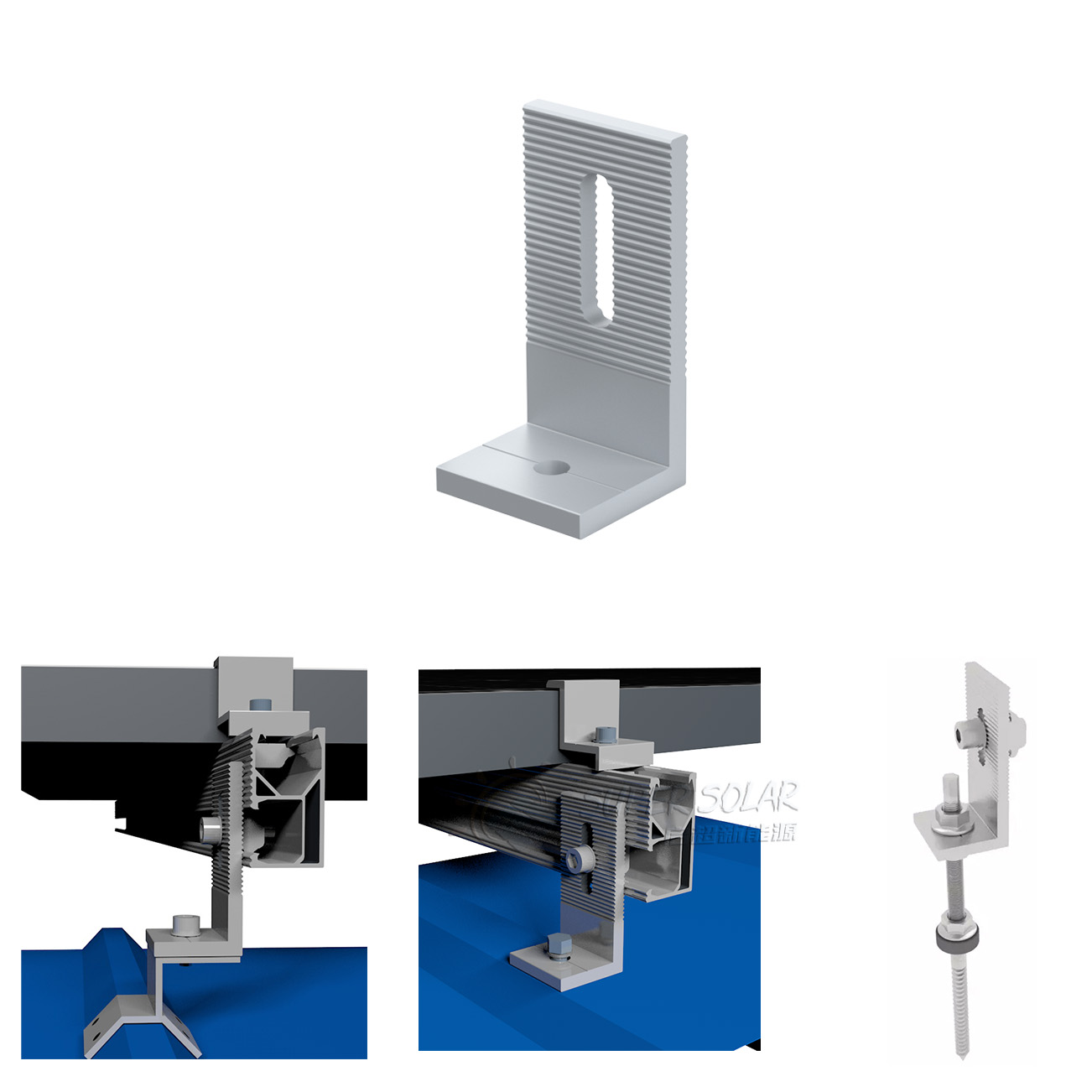

Easy and fast installation

Simplified process saves time

A major factor in the success of a metal roof project is how quickly it can be completed. L feet contribute to this by offering a simplified installation process. Pre-drilled holes and streamlined shapes reduce the number of steps required. Installers can mount rails and panels more efficiently, completing jobs faster without compromising safety. For businesses, this translates to lower labor costs and the ability to take on more projects within the same time frame.

Reducing errors and increasing reliability

How often do delays happen because of complex mounting systems? In a large metal roof project, even small mistakes can create costly setbacks. L feet are designed for straightforward use, reducing the chance of errors during installation. With consistent and standardized components, installers benefit from predictable performance. This reliability helps maintain project schedules and enhances customer satisfaction, which is essential in a competitive market.

Durable materials & corrosion resistance

Longevity in challenging environments

Every metal roof project faces environmental stress, from harsh sun exposure to heavy rainfall. L feet are typically manufactured from high-quality aluminum or stainless steel, offering long-term resistance to corrosion. For homeowners and businesses, this durability ensures that solar systems remain secure for decades. Installers appreciate the reduced risk of callbacks and warranty claims, making these materials a smart choice for long-term performance.

Corrosion resistance protects investment

Why does corrosion resistance matter so much in a metal roof project? Corrosion weakens structural integrity and reduces the effectiveness of solar mounting systems. By using L feet made with treated metals, installers can guarantee consistent performance even in coastal regions with salt air or areas with high humidity. This protection not only safeguards the installer’s reputation but also reassures clients that their investment will remain secure and efficient.

Cost-effective solution for large projects

Reducing total project costs

When handling a large-scale metal roof project, controlling expenses becomes essential. L feet help reduce costs by streamlining installation, minimizing the need for specialized tools, and lowering labor time. This combination ensures that overall budgets remain manageable, even for extensive commercial installations. Distributors also benefit by providing a solution that balances quality with affordability, meeting the demands of contractors working on tight budgets.

Maximizing return on investment

How can installers and property owners ensure that their investment delivers results? By choosing cost-effective mounting solutions like L feet, projects achieve a faster return on investment. Reduced installation time means savings on labor, while the long-term durability of the components minimizes maintenance expenses. For installers handling multiple metal roof projects per year, these savings add up, creating a significant financial advantage.

Flexible design options and adjustability

Adjustability to fit various configurations

A metal roof project often requires adjustments during installation. Roof angles, panel layouts, and site-specific conditions demand flexibility. L feet provide adjustability in height and positioning, ensuring solar panels can be aligned correctly for maximum efficiency. This adaptability reduces the need for custom components and allows installers to make quick changes on-site, keeping projects moving smoothly.

Meeting aesthetic and functional needs

Property owners often wonder: will solar systems look out of place on my roof? L feet allow for cleaner designs by integrating neatly with the structure of a metal roof project. The slim and functional design makes the installation visually appealing while maintaining structural stability. Installers can balance technical needs with customer preferences, ensuring the final project meets both performance and design expectations.

Why L feet are a smart choice for installers

Combining efficiency with reliability

The success of any metal roof project depends on using the right components. L feet combine wide compatibility, easy installation, durable materials, cost savings, and flexible design—all in one package. This makes them the ideal choice for installers who want to deliver reliable results on time and within budget.

Supporting growth in the solar industry

Why are L feet so central to the metal roof project market? Because they help installers adapt to the increasing demand for solar energy while maintaining high standards of quality. With more property owners investing in renewable energy, choosing mounting solutions that perform across different environments is essential. L feet offer the reliability and adaptability that make every project a success.

FAQs

Why are metal roof projects becoming more popular

Metal roof projects are growing because they offer durability, longevity, and compatibility with solar energy systems. They withstand extreme weather and provide a solid foundation for renewable energy adoption.

How do L feet improve the installation process

L feet simplify solar mounting on metal roofs by offering pre-drilled designs and universal compatibility. This reduces labor time, installation errors, and overall project costs, making them a reliable solution for installers.

What makes L feet durable for long-term use

L feet are manufactured from high-quality aluminum or stainless steel, providing excellent corrosion resistance. Their durability ensures solar systems remain secure on metal roof projects, even in harsh climates.

What information do installers need before choosing L feet

Installers should assess the type of metal roof project, roof profile, slope, and local conditions. By matching these factors with L feet’s flexibility and strength, installers can ensure reliable and efficient installations.