Common roof sheet types (trapezoidal, corrugated, standing seam)

When planning a solar mounting system on a metal roof project, understanding the roof sheet profile is essential. Trapezoidal, corrugated, and standing seam roofs each have unique designs that affect installation methods, load distribution, and waterproofing requirements. Trapezoidal sheets are common in commercial buildings, offering strength with their angular ridges. Corrugated sheets are often found in agricultural or residential structures, providing lightweight durability. Standing seam sheets are popular in modern projects, known for their sleek finish and hidden fasteners. Each type presents unique challenges for installers, making the correct choice of L foot a critical factor in ensuring stability, safety, and long-term performance.

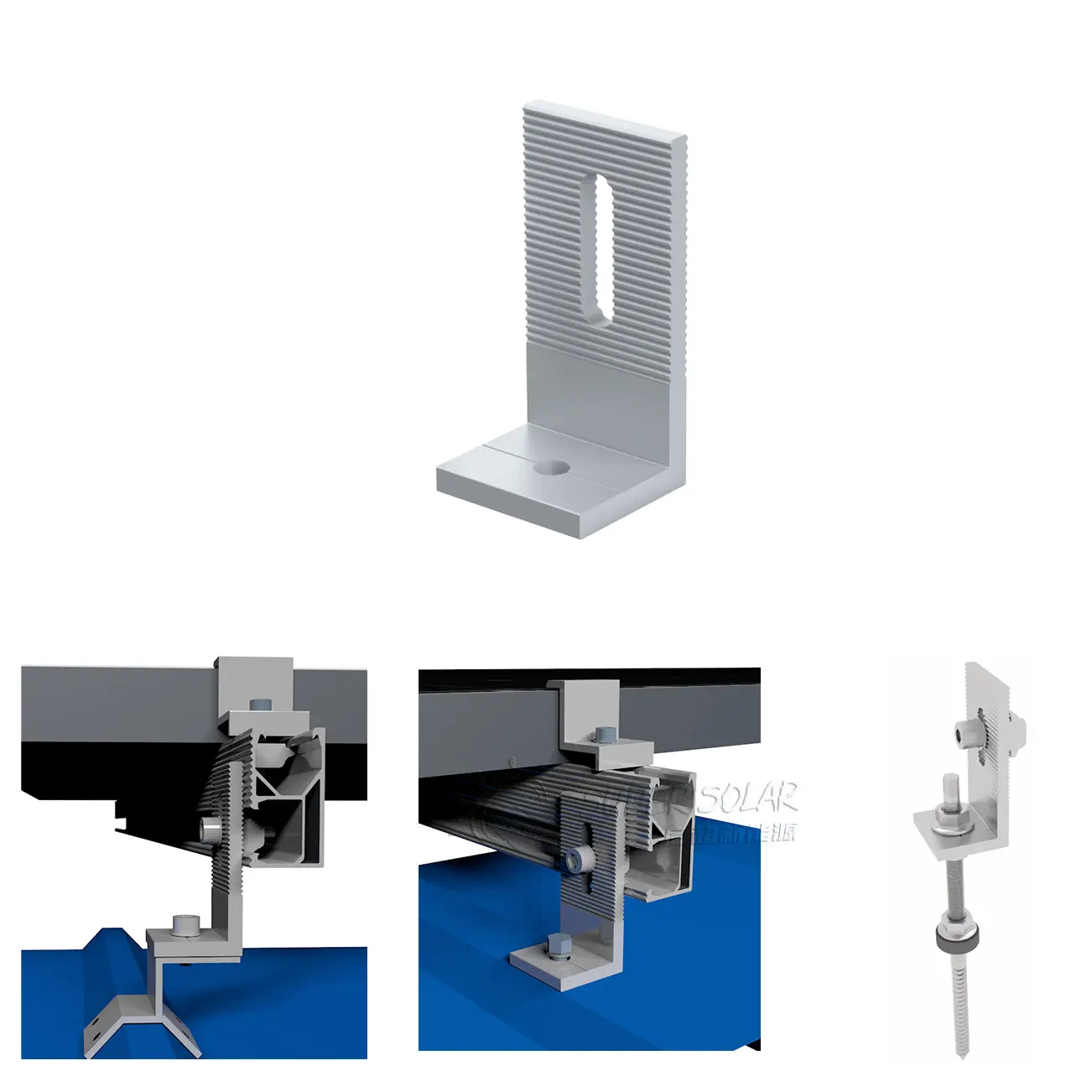

Matching the correct L foot to each roof profile

L feet for trapezoidal and corrugated sheets

Trapezoidal and corrugated sheets require L feet designed with broad bases and pre-installed rubber pads to ensure both stability and waterproofing. Installers often face the challenge of uneven contact points, making proper load distribution vital. Using specialized L feet for these profiles reduces the risk of leaks and improves structural reliability. For large-scale metal roof projects, this adaptability simplifies installation and ensures long-term performance under variable conditions.

L feet for standing seam roofs

Standing seam roofs cannot be penetrated without risking leaks. For this reason, clamp-style L feet are the preferred option. These clamp onto the seams securely, holding solar rails in place without drilling holes. Installers benefit from easier installation and property owners enjoy a fully waterproof system. Standing seam projects are often high-value metal roof projects, making it even more critical to use the correct non-penetrating L foot solution to maintain integrity.

Key selection criteria: load capacity, waterproofing, certifications

Evaluating load capacity in solar mounting

Every metal roof project must handle the combined weight of panels, rails, and environmental forces such as wind and snow. L feet with high load ratings ensure safety and compliance with engineering requirements. Installers should compare load capacities across different products to match them with local conditions. Distributors benefit by providing components that meet diverse needs, while property owners gain confidence knowing their system is built to last.

Waterproofing features for long-term protection

Leaks are one of the most common concerns in solar mounting. A poorly chosen L foot can compromise roof waterproofing, leading to structural damage. High-quality L feet incorporate EPDM rubber pads or integrated sealing designs. For trapezoidal and corrugated sheets, these seals prevent water ingress around screws. In standing seam projects, clamping-style L feet eliminate penetrations entirely. By focusing on waterproofing, installers protect both their reputation and the client’s investment.

Importance of certifications and compliance

How can distributors and installers trust that a product will perform as promised? Certifications provide assurance. Certified L feet are tested for load, corrosion resistance, and long-term durability under international standards. For metal roof projects in regulated markets, certifications are not optional but mandatory. Choosing certified products simplifies procurement and ensures the system passes inspection.

Mistakes to avoid when selecting L feet

Assuming all roof profiles use the same L foot

A common mistake is using a single type of L foot for every roof sheet. Trapezoidal, corrugated, and standing seam sheets require different designs. Using the wrong type can create alignment problems, leaks, or even system failure. Installers should always verify roof sheet profiles before selecting L feet. Distributors can support this process by educating customers and stocking diverse product ranges.

Overlooking waterproofing requirements

Another mistake is prioritizing load capacity while neglecting waterproofing. Even the strongest L foot is ineffective if it compromises the roof’s waterproof layer. Installers who ignore sealing solutions risk costly damage to client properties. The correct approach is to balance load and waterproofing together, ensuring performance across every metal roof project.

Ignoring certification and quality standards

In competitive markets, cheaper, uncertified products are tempting. But ignoring certification exposes projects to risks such as corrosion, weak performance, and failure under load. Installers who use uncertified L feet may face warranty claims or even legal disputes. Certified products provide peace of mind, long-term durability, and compliance with building codes.

Checklist for distributors and installers before purchasing

Distributor checklist

Distributors should first confirm product certifications, then evaluate compatibility with the most common roof sheet profiles in their region. Stocking versatile L feet for trapezoidal, corrugated, and standing seam roofs ensures they can meet broad market demand. Verifying supply chain reliability is also critical, as installers depend on timely deliveries. Offering product training materials adds value and builds customer trust.

Installer checklist

Installers should assess project-specific needs before purchasing. This includes verifying roof profile, checking load capacity requirements, and ensuring waterproofing features are included. They should also request certificates and technical datasheets from distributors. By following a structured checklist, installers avoid costly mistakes and guarantee that their metal roof project is secure, efficient, and durable.

FAQs

What roof profiles require specialized L feet

Trapezoidal, corrugated, and standing seam roof profiles each require different types of L feet. Clamp-style L feet are best for standing seams, while trapezoidal and corrugated sheets require wide-base options with waterproofing pads.

Why is waterproofing critical when installing L feet

Without proper waterproofing, leaks can occur that damage the building and shorten roof lifespan. L feet with sealing pads or clamp-style solutions protect the integrity of the roof during solar mounting.

How important are certifications for L feet

Certifications ensure that L feet meet international standards for load, durability, and corrosion resistance. They provide confidence for installers and compliance with building codes for distributors and property owners.

What should installers check before buying L feet

Installers should review the roof profile, load requirements, waterproofing features, and certification documents. Following a checklist ensures the correct product is chosen for every metal roof project.