Roof Type as the Starting Point for System Selection

When buyers search for roof mounts for solar panels, they are usually not looking for a single product recommendation. Instead, they are trying to understand which mounting solution fits their specific roof type and whether that solution is practical in terms of installation speed, compatibility, and long-term reliability. Roof structure, roofing material, load capacity, and waterproofing logic all directly influence the choice of mounting system.

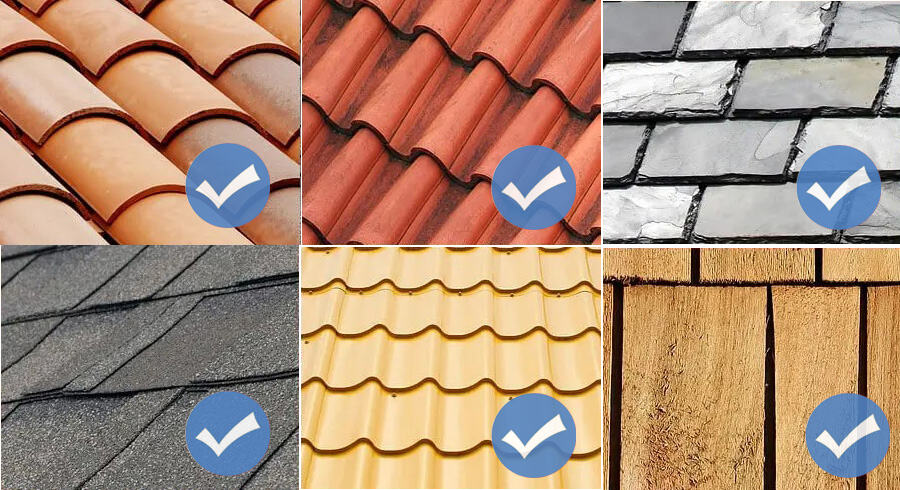

In practice, there is no truly universal roof mount that works optimally across all roof types. Tile roofs, metal roofs, and flat roofs each require different load paths, attachment methods, and sealing strategies. Attempting to apply a one-size-fits-all solution often leads to installation challenges, increased labor time, or higher long-term maintenance risk.

This guide is structured as a hub-style overview. It maps common roof types to their corresponding roof mounts for solar panels, explains the advantages and limitations of each approach, and compares installation complexity to support informed decision-making before purchase.

Tile Roof Solutions for Solar Panel Mounting

Tile roofs are common in residential and low-rise commercial buildings, particularly across Europe, parts of Asia, and regions with traditional architectural styles. Mounting solar systems on tile roofs requires careful consideration of tile shape, brittleness, and waterproofing layers.

Hook and Rail Systems for Tile Roofs

The most widely used roof mounts for solar panels on tile roofs are based on a hook and rail configuration. In this system, stainless steel or aluminum hooks are anchored directly into the roof rafters beneath the tiles. Aluminum rails are then fixed to the hooks, providing a continuous mounting platform for modules.

This approach allows structural loads to bypass the tiles and transfer directly into the roof structure. When properly designed, the hook passes through or around the tile with minimal modification, preserving the roof’s original drainage behavior. Adjustable hooks are often used to accommodate variations in tile thickness and batten height.

Compatibility Across Tile Types

Tile roofs are not uniform. Flat tiles, Roman tiles, and Spanish tiles each present different profiles and clearance requirements. Effective roof mounts for solar panels must offer hook variants or adjustment ranges that match these differences.

Flat tiles generally allow simpler hook geometries, while curved tiles require offset or extended hooks to avoid point loading. Systems that support multiple hook options within the same rail platform are more versatile for installers and distributors serving mixed markets.

Advantages and Limitations

Tile roof mounting systems offer strong structural performance and long-term reliability when installed correctly. They are well suited for pitched roofs and allow flexible module orientation.

However, installation complexity is higher compared to metal roofs. Tile removal, cutting, and replacement require skilled labor, and improper handling can lead to cracked tiles or water ingress. As a result, tile roof solutions prioritize precision over speed.

Metal Roof Solutions for Solar Panel Mounting

Metal roofs are increasingly popular in both residential and commercial construction due to their durability and clean structural lines. Roof mounts for solar panels on metal roofs typically emphasize speed, simplicity, and minimal roof penetration.

Standing Seam Clamp Systems

For standing seam metal roofs, clamp-based mounting systems are often the preferred solution. These clamps attach directly to the raised seams without penetrating the roof surface. Rails or module clamps are then fixed to the seam clamps.

This non-penetrating approach preserves roof warranties and significantly reduces waterproofing risk. Installation is fast, repeatable, and well suited for large commercial rooftops. Compatibility depends on seam geometry, so clamp selection must match the specific seam profile.

Trapezoidal and Corrugated Metal Roof Mounts

On trapezoidal or corrugated metal roofs, mounting systems typically use self-drilling screws with EPDM sealing washers. Rails are fixed through the metal sheet into the underlying purlins or decking.

While this method involves roof penetration, proper sealing and fastening patterns ensure long-term weather resistance. Some systems integrate short rail or rail-less solutions to reduce material use and installation time.

Advantages and Limitations

Metal roof mounting solutions are among the fastest to install. They often require fewer components and less on-site adjustment, making them attractive for projects with tight schedules.

The main limitation lies in compatibility. Not all clamps fit all seam profiles, and incorrect clamp selection can compromise grip strength. For penetrative systems, careful sealing is essential to avoid leaks over time.

Flat Roof Solutions for Solar Panel Mounting

Flat roofs are common in commercial, industrial, and institutional buildings. Unlike pitched roofs, flat roofs require mounting systems that create the correct tilt angle while managing wind uplift and roof loading.

Ballasted Mounting Systems

Ballasted systems are a common category of roof mounts for solar panels on flat roofs. They rely on weight, typically concrete blocks, to hold the array in place without penetrating the roof membrane.

This approach minimizes waterproofing risk and is often preferred where roof warranties or membrane integrity are critical. System design must account for wind zones, roof load capacity, and friction between the mounting base and roof surface.

Mechanically Attached Flat Roof Systems

In some cases, mechanical attachment is used to reduce ballast weight or increase wind resistance. Anchors penetrate the roof and tie the mounting structure directly into the building structure below.

This method provides strong uplift resistance and can reduce overall system weight. However, it introduces waterproofing complexity and requires coordination with roofing specialists to ensure proper sealing.

Advantages and Limitations

Flat roof mounting systems offer design flexibility and are suitable for large-scale installations. They can be optimized for row spacing, tilt angle, and maintenance access.

Installation complexity varies. Ballasted systems simplify waterproofing but increase handling and logistics requirements. Mechanically attached systems reduce ballast but demand precise installation and sealing.

Comparison of Solutions by Installation Complexity

Installation speed and labor requirements are often decisive factors during the buying stage. Roof mounts for solar panels differ significantly in this regard depending on roof type and mounting approach.

Metal roof systems generally offer the fastest installation. Clamp-based standing seam solutions require minimal components and no roof penetration, making them highly efficient for experienced crews.

Tile roof systems involve the highest installation complexity. Tile handling, hook alignment, and waterproofing checks increase labor time. These systems reward careful installation with long-term reliability but are less forgiving of errors.

Flat roof systems fall between the two extremes. Ballasted systems require careful layout and weight placement, while mechanically attached systems require coordination across trades. Installation speed depends heavily on system design and site conditions.

Evaluating Whether a System Is Truly Universal

Many buyers ask whether roof mounts for solar panels can be used across different roof types. In practice, universality usually applies at the platform level rather than the component level.

Rail systems, module clamps, and fastening standards can often be shared across tile, metal, and flat roof solutions. However, roof interface components such as hooks, clamps, or bases are roof-specific.

Manufacturers that design modular systems allow installers and distributors to reuse core components while swapping roof-specific parts. This approach improves inventory efficiency without compromising installation quality.

Durability, Maintenance, and Long-Term Performance

Beyond installation, long-term performance is a key consideration. Roof mounts for solar panels must withstand environmental exposure, thermal movement, and cyclic loads over decades.

Material selection plays a major role. Anodized aluminum offers corrosion resistance and lightweight handling, while stainless steel provides strength in high-load or aggressive environments. Coating quality, fastener compatibility, and drainage design all influence maintenance needs.

Systems designed with clear load paths and minimal stress concentrations tend to require less inspection and adjustment over time. For buyers, evaluating these design details helps distinguish mature solutions from generic offerings.

Using This Guide as a Hub for Deeper Evaluation

Because this topic spans multiple roof types and solutions, this article is best used as a starting point. Each roof category can be explored in greater depth through dedicated guides that address specific installation details, regional considerations, and product specifications.

For buyers in the pre-purchase phase, understanding how roof type maps to mounting solution narrows the field quickly. From there, deeper evaluation can focus on compatibility, installation workflow, and supplier capability.

Roof mounts for solar panels are not interchangeable accessories. They are structural interfaces that directly affect system safety, installation efficiency, and long-term reliability. Starting with the right solution framework is the most effective way to reduce risk and improve project outcomes.

FAQ

Which roof mounts for solar panels are suitable for residential buildings

Residential buildings commonly use tile roof or metal roof mounting systems, depending on roof material. Selection should prioritize roof compatibility, waterproofing integrity, and installation precision.

Are there roof mounts for solar panels that work on multiple roof types

Core components like rails and clamps can often be shared, but roof interface parts are typically roof-specific. Modular systems offer the closest practical alternative to universal solutions.

Which roof type offers the fastest solar installation

Metal roofs, especially standing seam designs, generally allow the fastest installation due to clamp-based, non-penetrating mounting methods.

How should installation complexity influence purchasing decisions

Installation complexity affects labor cost, project timelines, and error risk. Buyers should balance upfront product cost against installation efficiency and long-term reliability.

Table of Contents

- Roof Type as the Starting Point for System Selection

- Tile Roof Solutions for Solar Panel Mounting

- Metal Roof Solutions for Solar Panel Mounting

- Flat Roof Solutions for Solar Panel Mounting

- Comparison of Solutions by Installation Complexity

- Evaluating Whether a System Is Truly Universal

- Durability, Maintenance, and Long-Term Performance

- Using This Guide as a Hub for Deeper Evaluation

- FAQ

- Which roof mounts for solar panels are suitable for residential buildings

- Are there roof mounts for solar panels that work on multiple roof types

- Which roof type offers the fastest solar installation

- How should installation complexity influence purchasing decisions