Mounting Clamp Selection as a Specification Decision

For installers, EPCs, and distributors involved in large-scale or repeat solar projects, solar panel mounting clamps are not a conceptual product category but a specification item. Buyers already understand what mid clamps and end clamps do. The real purchasing decision revolves around size accuracy, rail compatibility, material durability, and whether the clamps can be supplied consistently in bulk with controlled tolerances.

In procurement scenarios, a mismatch of just a few millimeters or an incompatible rail interface can delay installation across an entire site. That is why experienced buyers evaluate mounting clamps based on measurable specifications rather than general descriptions. This article focuses on those practical criteria, addressing the confirmation questions most commonly raised during bulk purchasing.

Mid Clamp and End Clamp Functional Differences

Mid clamps and end clamps serve distinct structural and layout roles within a module array. Understanding their functional differences helps ensure correct quantity planning and compatibility assessment.

Mid Clamp Role in Module Arrays

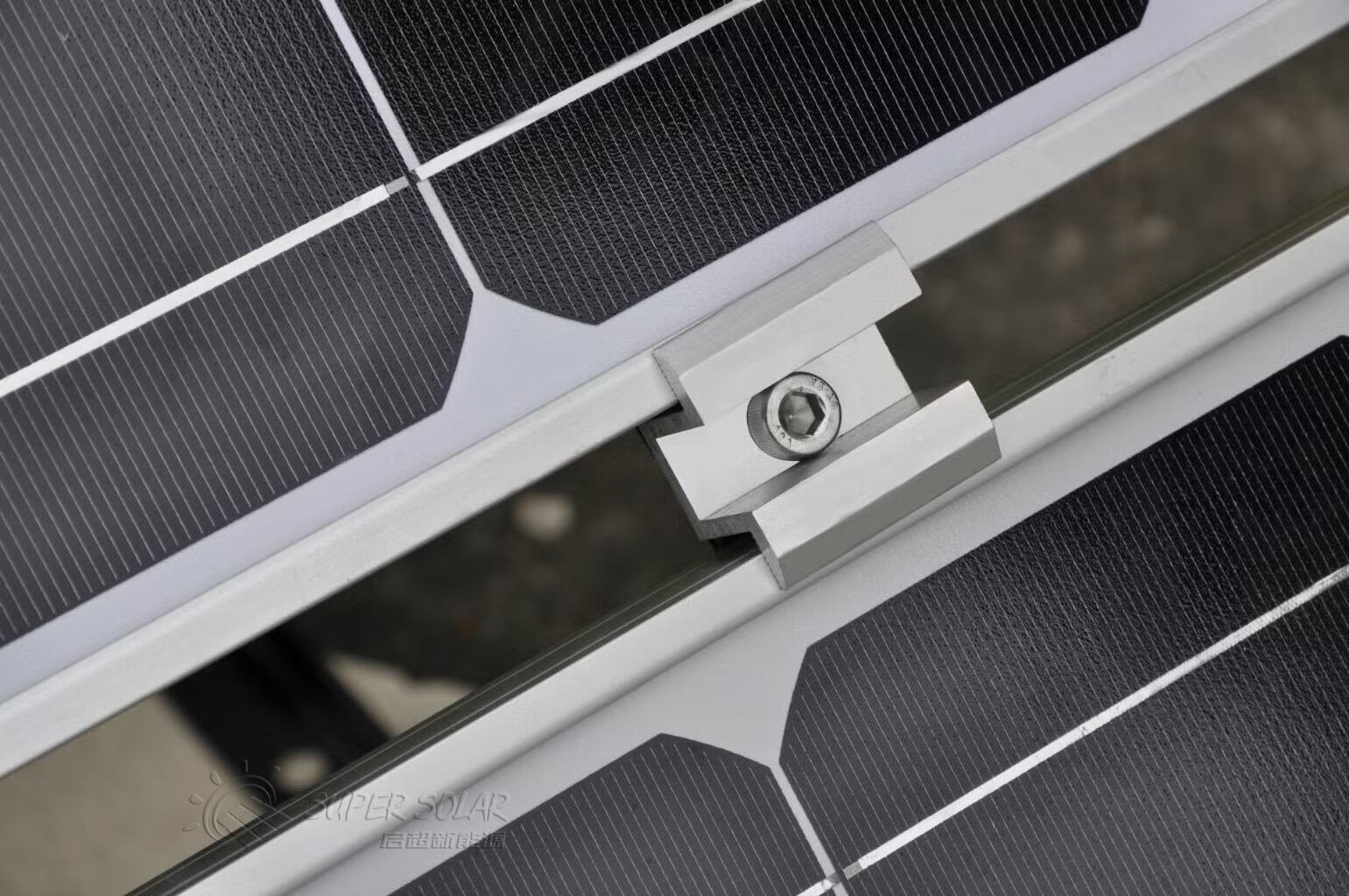

Mid clamps secure the internal edges between two adjacent solar modules. Their height corresponds directly to the module frame thickness, making size accuracy critical. A correctly sized mid clamp maintains even pressure across both module frames without introducing torsional stress.

In bulk installations, uniform mid clamp performance contributes to consistent array alignment and load distribution. Poorly machined clamps or incorrect heights can cause uneven clamping force, leading to micro-movement over time. For this reason, buyers often prioritize tight dimensional tolerances when sourcing mid clamps in volume.

End Clamp Role and Edge Stability

End clamps secure the outermost module edges of an array. Unlike mid clamps, end clamps interact with only one module frame, but they are equally important for overall system stability. They must resist uplift forces while maintaining aesthetic alignment along the array perimeter.

End clamp selection must match both the module frame height and the rail profile. Inconsistent sizing can result in visible height differences across rows, which is unacceptable in commercial and utility-facing projects. Bulk buyers typically require end clamps that match mid clamp finishes and material properties to ensure visual and mechanical consistency.

Quantity Planning for Bulk Orders

In large projects, accurate clamp quantity calculations reduce excess inventory and on-site shortages. Standard practice involves one mid clamp per shared module edge and one end clamp per outer edge. However, rail layout and module orientation can affect exact quantities. Suppliers that support bulk procurement often provide bill-of-material guidance to streamline ordering.

Clamp Size Standards and Frame Compatibility

Clamp size is one of the most critical confirmation points in solar panel mounting clamps procurement. The most common sizes correspond to module frame thickness rather than arbitrary standards.

30 mm Frame Applications

Thirty millimeter clamps are typically used with thin-frame modules, often found in residential or lightweight commercial installations. These clamps require precise machining due to the reduced contact surface area. Even small deviations can affect clamping force.

For bulk buyers, consistency across production batches is especially important for 30 mm clamps. Variations can result in uneven pressure distribution, increasing the risk of module frame deformation over time.

35 mm as the Most Common Size

Thirty-five millimeter is currently the most widely used clamp size in commercial solar projects. It balances structural rigidity and compatibility across a wide range of module brands. As a result, many distributors treat 35 mm solar panel mounting clamps as a core inventory item.

Because of their widespread use, buyers often request compatibility confirmation across multiple module suppliers when sourcing 35 mm clamps. Reliable manufacturers maintain strict dimensional control to ensure cross-brand compatibility.

40 mm Frame and Heavy-Duty Modules

Forty millimeter clamps are designed for thicker, reinforced module frames, often used in utility-scale or high-wind applications. These clamps experience higher mechanical loads and must be manufactured from materials with sufficient strength and fatigue resistance.

Bulk procurement of 40 mm clamps typically involves additional verification of load ratings and material certifications. Buyers may also request test data to support structural calculations.

Rail Compatibility and Universal Interface Design

Rail compatibility is a decisive factor when selecting solar panel mounting clamps, particularly for distributors serving multiple mounting system brands.

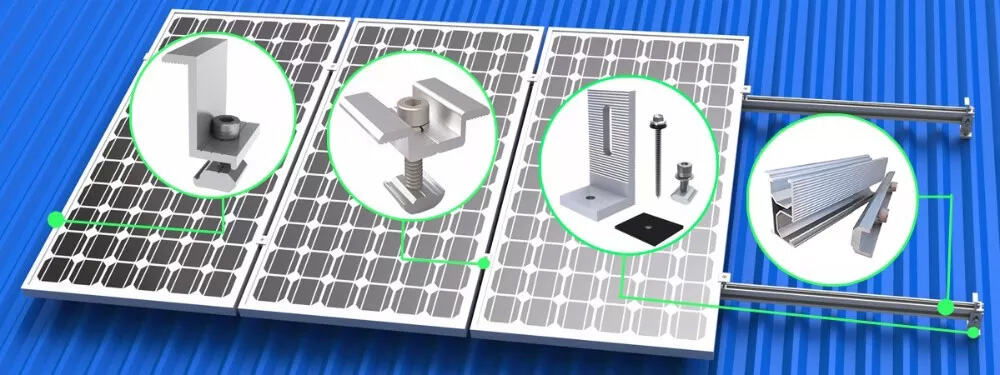

Standard T-Slot and Top-Mount Interfaces

Most modern clamps are designed to interface with standard aluminum rails using T-slot nuts or top-mount bolts. A universal interface allows clamps to be used across different rail profiles without modification.

Buyers involved in multi-brand projects often prioritize clamps that support common slot dimensions and bolt sizes. This reduces SKU complexity and simplifies inventory management across different system configurations.

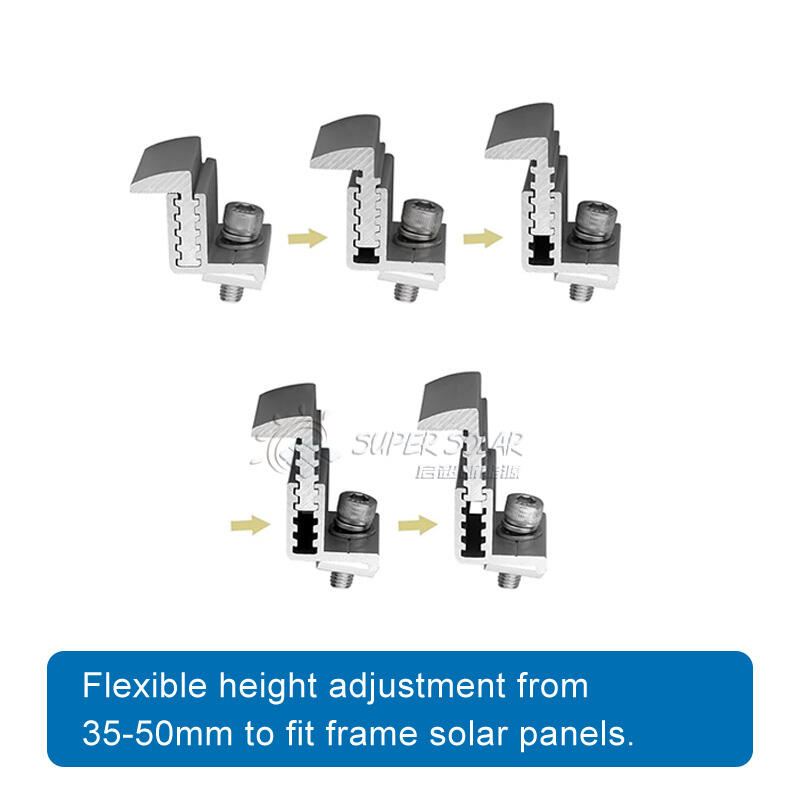

Adjustable Clamp Geometry for Tolerance Control

Some clamps feature adjustable or floating nut designs that compensate for minor rail manufacturing tolerances. This flexibility can be valuable in retrofit projects or when combining components from different suppliers.

From a bulk supply perspective, clamps with adaptable interfaces reduce compatibility-related returns and on-site installation issues. This is particularly important when supplying international markets with varying rail standards.

Avoiding Proprietary Lock-In

Distributors generally prefer solar panel mounting clamps that are not locked to proprietary rail systems. Universal compatibility allows greater sourcing flexibility and reduces dependency on a single supplier. Manufacturers that design clamps around widely accepted interface standards tend to be favored in long-term supply agreements.

Material Options and Surface Treatment

Material selection directly affects durability, corrosion resistance, and long-term performance. Buyers evaluating clamps in bulk focus on material consistency and surface treatment quality rather than basic material descriptions.

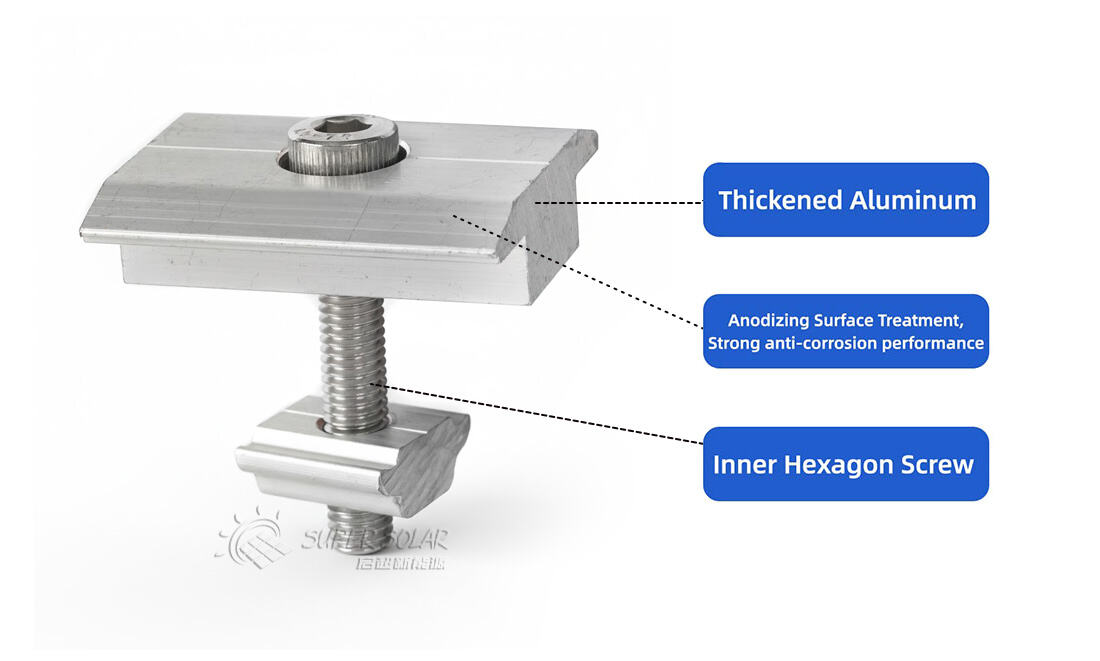

Anodized Aluminum Clamps

Anodized aluminum is widely used due to its balance of strength, weight, and corrosion resistance. Anodization improves surface hardness and provides a uniform finish that matches aluminum rails aesthetically.

For bulk orders, buyers often specify anodization thickness and color consistency. Uniform anodizing ensures that clamps installed across large arrays maintain a consistent appearance and predictable corrosion performance.

Stainless Steel Clamps and Components

Stainless steel is typically used for higher-load applications or in aggressive environments such as coastal or industrial zones. Some clamp designs use stainless steel bodies, while others combine aluminum bodies with stainless steel fasteners.

Material grade consistency is critical in bulk procurement. Buyers may request confirmation of stainless steel grades to ensure resistance to corrosion and galling during installation.

Mixed Material Assemblies

Many solar panel mounting clamps combine anodized aluminum bodies with stainless steel bolts and nuts. This hybrid approach balances cost and performance. However, proper material pairing is essential to avoid galvanic corrosion.

Manufacturers supplying clamps at scale must demonstrate control over material sourcing and assembly processes to ensure long-term reliability.

Compatibility with Module Brands and System Layouts

Bulk buyers often work with multiple module brands across different projects. As a result, clamp compatibility must be validated beyond nominal frame height.

Module frame lip design, corner radius, and coating thickness can all influence clamp fit. Well-designed clamps accommodate these variations without compromising clamping force.

Suppliers that provide compatibility lists or testing references help buyers reduce uncertainty during procurement. This information is especially valuable when modules change between project phases.

Customization and OEM Supply Options

For distributors, customization capability is often as important as technical specifications. Solar panel mounting clamps are frequently supplied under private-label programs.

Customization may include laser marking, packaging design, color variations, or bundled kits with bolts and nuts. OEM support allows distributors to differentiate their offerings while maintaining consistent technical performance.

Manufacturers with established bulk supply processes can support custom requirements without disrupting lead times or quality control. This capability is particularly relevant for buyers planning long-term procurement contracts.

Bulk Supply Capacity and Quality Consistency

Bulk purchasing introduces requirements beyond individual product performance. Consistency across thousands or millions of units becomes the primary concern.

Reliable bulk suppliers implement batch tracking, dimensional inspection, and surface finish control throughout production. This ensures that clamps delivered months apart remain interchangeable without installation adjustments.

Lead time stability, packaging durability, and logistics coordination are also part of bulk supply evaluation. Buyers often assess suppliers based on their ability to deliver repeatable quality rather than one-off samples.

FAQ

How do I confirm the correct size of solar panel mounting clamps

Clamp size should match the module frame thickness exactly. Confirm the nominal frame height from the module datasheet and select clamps designed specifically for that dimension.

Are solar panel mounting clamps compatible with all rails

Compatibility depends on the clamp interface and rail slot design. Clamps with universal T-slot or top-mount interfaces are generally compatible with most standard aluminum rails.

Is anodized aluminum suitable for outdoor installations

Anodized aluminum provides good corrosion resistance for most environments. In highly corrosive locations, stainless steel or enhanced coatings may be preferred.

Can solar panel mounting clamps be customized for OEM supply

Yes, many manufacturers support OEM customization, including branding, packaging, and configuration options, especially for bulk orders.

Table of Contents

- Mounting Clamp Selection as a Specification Decision

- Mid Clamp and End Clamp Functional Differences

- Clamp Size Standards and Frame Compatibility

- Rail Compatibility and Universal Interface Design

- Material Options and Surface Treatment

- Compatibility with Module Brands and System Layouts

- Customization and OEM Supply Options

- Bulk Supply Capacity and Quality Consistency

- FAQ

- How do I confirm the correct size of solar panel mounting clamps

- Are solar panel mounting clamps compatible with all rails

- Is anodized aluminum suitable for outdoor installations

- Can solar panel mounting clamps be customized for OEM supply