Solar Mid Clamp

Our solar mid clamps are widely used in tile roof, metal roof, and flat roof solar mounting systems.

Supporting residential, commercial, and industrial PV installations.

Send inquiry for bulk price. ↓↓

- Overview

- Recommended Products

Reliable Module Fixing Solution for Rooftop Solar Mounting Systems

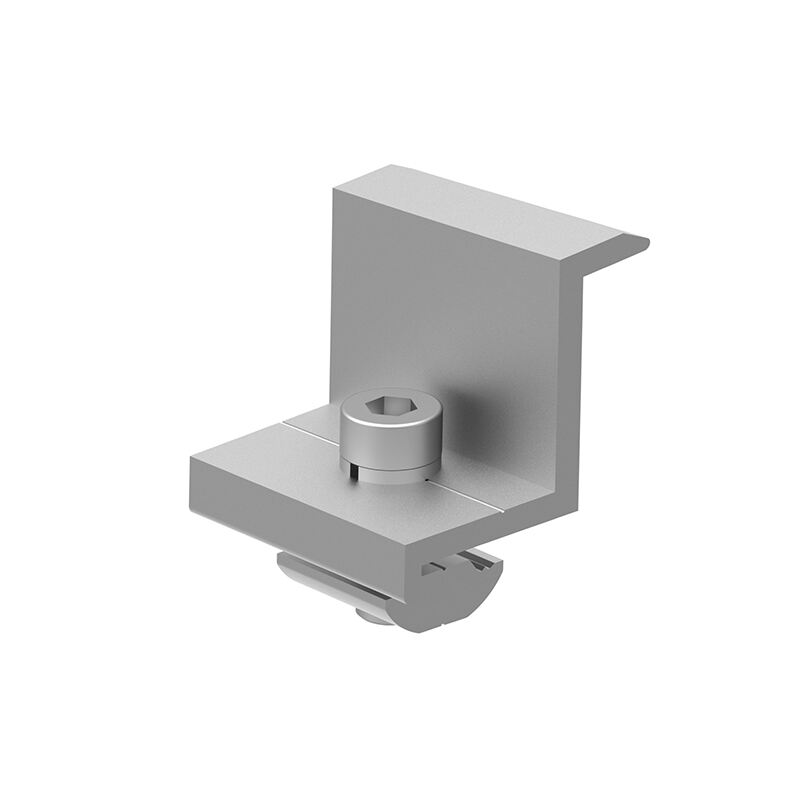

Product Overview

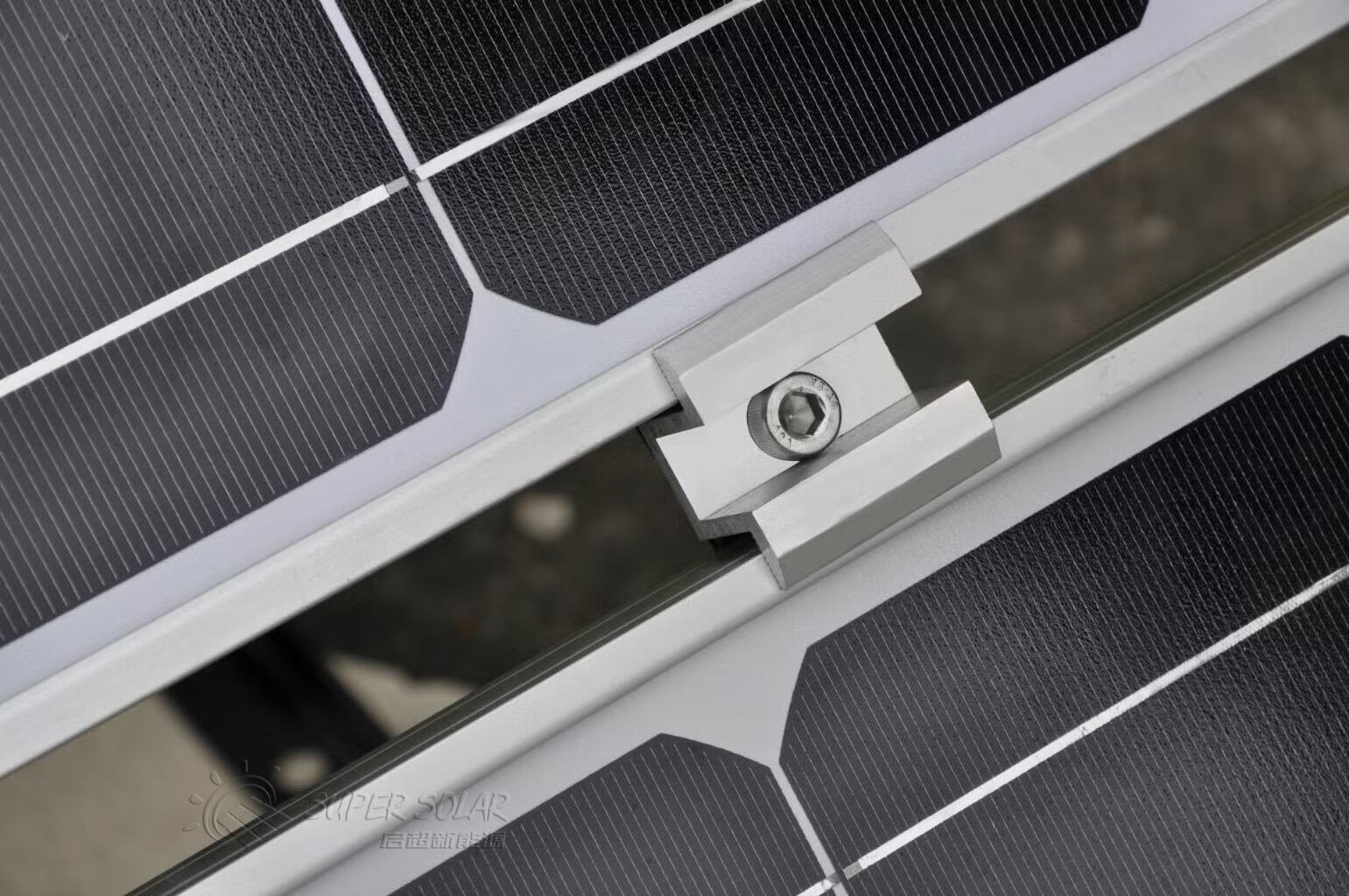

The Solar Mid Clamps a core component used to secure photovoltaic modules between adjacent panels in roof solar mounting systems.

Designed for strength, precision, and compatibility, Super Solar’s mid clamps ensure stable module fixation while maintaining proper spacing and alignment.

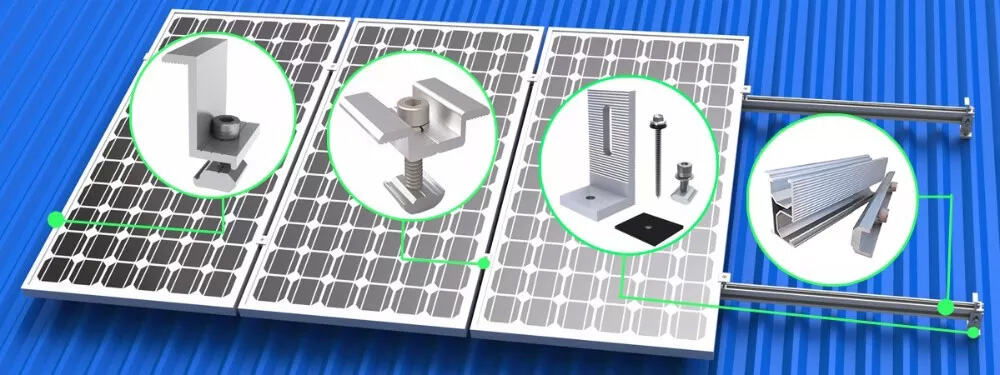

Our solar mid clamps are widely used in tile roof, metal roof, and flat roof solar mounting systems, supporting residential, commercial, and industrial PV installations.

Key Functions of Solar Mid Clamp

- Secure adjacent solar modules firmly on mounting rails

- Maintain consistent module spacing

- Transfer wind and snow loads safely to the mounting structure

- Ensure long-term structural stability of rooftop PV systems

Product Features & Advantages

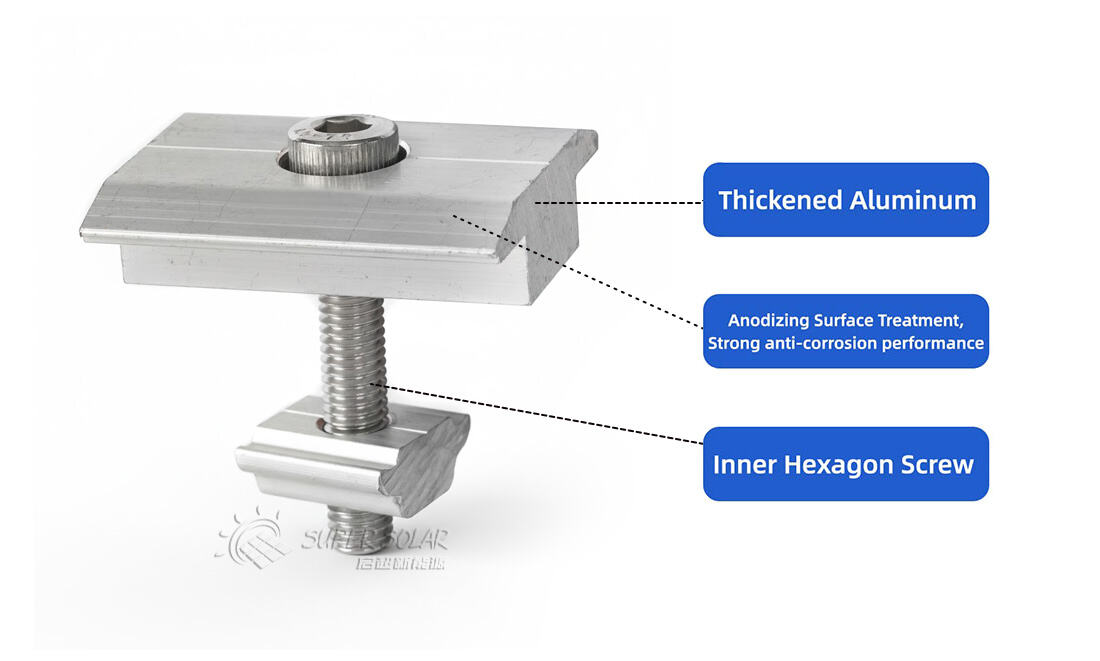

High Structural Strength

- Manufactured from high-strength aluminum alloy

- Designed to withstand high wind and snow loads

- Suitable for long-term outdoor exposure

Universal Compatibility

- Compatible with most framed solar modules

- Works with standard aluminum solar rails

- Suitable for various roof mounting systems

Precise Module Spacing

- Standard spacing ensures professional system appearance

- Supports optimized module ventilation and heat dissipation

Fast & Easy Installation

- Pre-assembled design available

- Reduced installation time on-site

- Installer-friendly structure

---

Material & Surface Treatment

- Material: Aluminum Alloy (AL6005-T5 )

- Fasteners: Stainless Steel (SUS304l)

- Surface Treatment: Anodized aluminum

- Corrosion Resistance: Suitable for coastal and high-humidity environments

---

Technical Specifications (Customizable)

| Parameter | Options |

| Module Thickness | 30mm / 35mm / 40mm / Custom |

| Clamp Length | Standard / Customized |

| Bolt Size | M8 / M10 |

| Color | Silver / Black / Custom |

| Installation Position | Between adjacent modules |

Custom specifications available upon request.

---

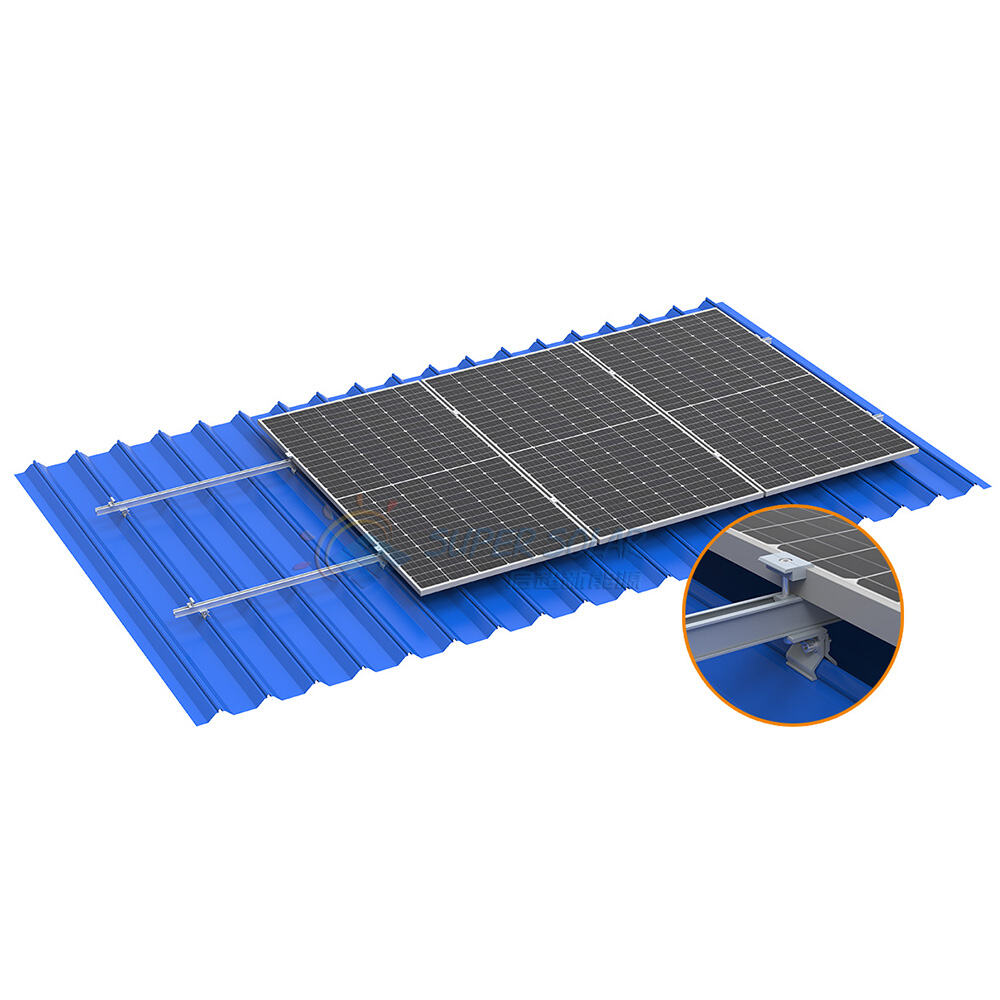

Application Scenarios

Solar mid clamps are commonly used in:

- Tile roof solar mounting systems

- Metal roof solar mounting systems

- Flat roof solar mounting systems

- Residential rooftop PV projects

- Commercial & industrial rooftop installations

---

Quality & Engineering Assurance

- Designed according to international mounting standards

- Structural calculation support available

- Consistent dimensional accuracy

- Tested for mechanical strength and durability

---

OEM & Customization Services

Super Solar provides full OEM and customization support:

- Custom clamp dimensions

- Private label & logo marking

- Customized packaging sets

- Pre-assembled clamp kits for installers

- Engineering drawings and BOM support

> For detailed installation, compatibility, and certification questions, please refer to the FAQ section below.

FAQ

Product Compatibility

1.Which module frame thicknesses do your clamps support?

Our clamps support common module frame thicknesses (30–40 mm), with adjustable options available.

2.Are clamps suitable for all PV module brands?

They are suitable for most mainstream PV module brands when installed according to guidelines.

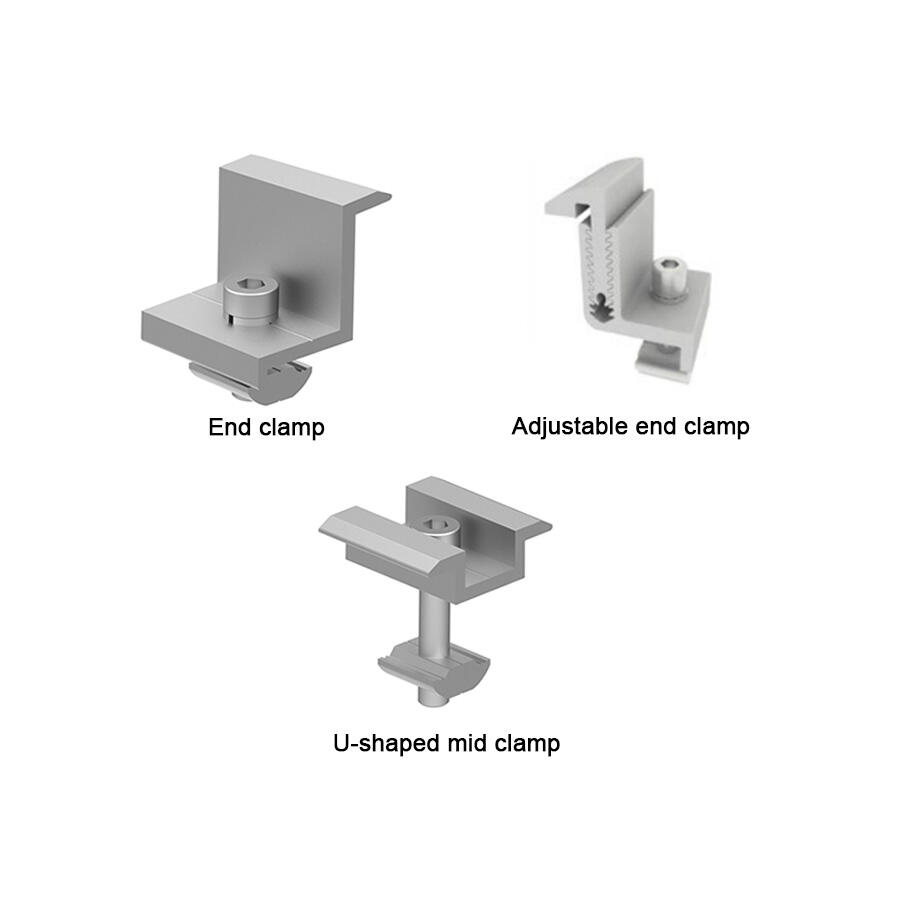

3.Do you provide mid clamps, end clamps, and L-clamps for different applications?

We supply mid clamps, end clamps, and L-clamps for different mounting scenarios.

4.Are clamps compatible with bifacial modules?

Dedicated solutions are available for bifacial modules.

5.Can clamps be used for metal roofs, flat roofs, and ground mounts?

Clamps can be used in rooftop and ground-mounted PV systems.

6.Do you offer clamps for rail-less mounting systems?

Rail-less clamp solutions are available for specific system designs.

Technical / Engineering

7.What is the maximum pull-out strength of your clamps?

Pull-out and shear strength are verified through internal load testing.

8.Are torque and load test reports available?

Torque and load test reports are available upon request.

9.Do your clamps comply with UL 2703, CE, or TUV standards?

Our mounting systems are designed to meet UL, CE, or TÜV requirements depending on the market.

10.Are your clamps resistant to corrosion in coastal areas?

Corrosion resistance is validated through material selection and surface treatment.

11.What materials are used – AL6005-T5, SUS304, or galvanized steel?

Materials include AL6005-T5 aluminum and SUS304 stainless steel.

12.Do you provide structural calculations for wind and snow loads when using your clamps?

Structural calculations for wind and snow loads can be provided at the system level.

Installation & Design

13.How many clamps per module are recommended?

Clamp quantity is determined by module size and load conditions.

14.Do you provide torque specifications for installation?

Torque specifications are clearly defined in installation manuals.

15.Are installation manuals and CAD drawings available?

CAD drawings and installation guides are available.

16.Can clamps be used with adjustable tilt legs?

Clamps are compatible with adjustable tilt structures when specified.

17.Can clamps handle thermal expansion without damaging modules?

Thermal expansion is addressed through system design and clamp positioning.

18.Is pre-assembly required before installation on the rails?

Pre-assembled clamps reduce installation time on-site.

19. How to ensure even pressure on panels with clamps?

Even pressure is ensured through defined clamping zones and torque control.

Commercial / Procurement

19.What information is required for a quotation?

Quotation requires module size, roof type, project location, and quantity

20.What is the lead time for bulk orders?

Bulk order lead time is typically 2–4 weeks.

21.Do you provide OEM / ODM services for solar clamps?

OEM / ODM services are available.

22.What is the minimum order quantity (MOQ)?

MOQ depends on clamp type.

23.How are clamps packaged for shipping?

Clamps are packaged in export-ready cartons or pallets.

24.Are sample kits available for testing?

Sample kits are available for testing.

25.Do you have references or case studies using your clamps?

Project references can be shared upon request.

27. What warranty do you offer for solar clamps?

Standard warranty aligns with mounting system warranty terms.

---

Why Choose Super Solar Solar Mid Clamp

- Specialized solar mounting manufacturer

- Stable mass production capacity

- Strict quality control system

- Global supply experience

- Professional B2B technical support

---

Related Solar Mounting Components

For a complete roof solar mounting system, solar mid clamps are typically used together with:

- Solar End Clamp

- Aluminum Solar Rail

- Solar Roof Hook

- Standing Seam Solar Clamp

- Hanger Bolt System

All components are designed for full system compatibility.

---

Request a Quotation or Sample

Looking for a reliable solar mid clamp supplier for your rooftop PV project?

Contact Super Solar to receive:

- Technical specifications

- Sample support

- OEM solutions

- Competitive quotation

→ Contact Us for Solar Mid Clamp Solutions