Comprehensive Compatibility and Customization Solutions

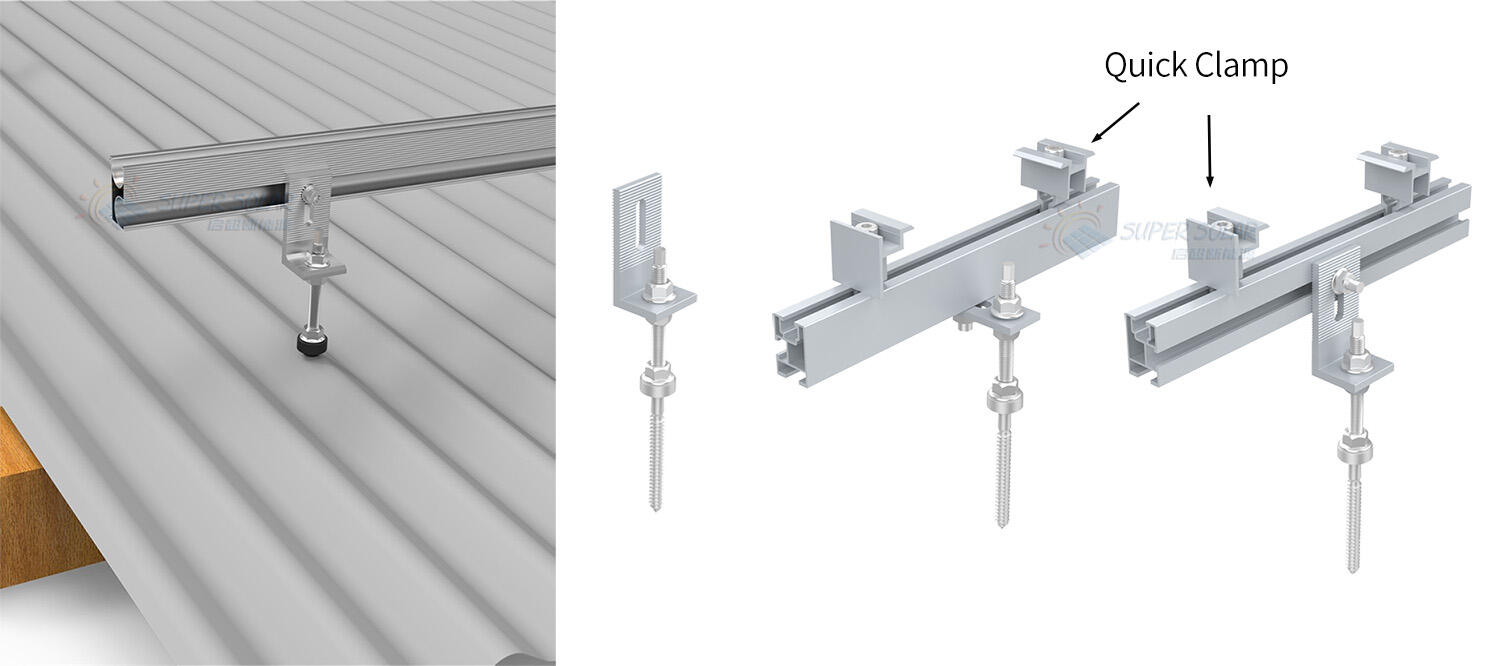

Metal roof solar brackets manufacturers excel in providing comprehensive compatibility solutions that accommodate the vast diversity of metal roofing systems found across residential, commercial, and industrial applications. This versatility represents a significant competitive advantage, as these manufacturers have invested extensively in research and development to create mounting solutions that work seamlessly with virtually every metal roof profile available in the market. The compatibility expertise extends beyond simple attachment mechanisms to include detailed understanding of thermal expansion characteristics, material properties, and installation requirements specific to each roof type. Metal roof solar brackets manufacturers maintain extensive databases of roof profiles and specifications, enabling them to provide precise mounting recommendations and custom solutions when standard products cannot meet specific project requirements. The customization capabilities of these manufacturers allow for modifications in bracket dimensions, attachment methods, and material specifications to address unique installation challenges or performance requirements. This flexibility proves invaluable for solar installers working on complex projects involving irregular roof configurations, extreme environmental conditions, or specialized performance criteria. The comprehensive approach includes detailed technical documentation, installation guides, and engineering certifications that streamline the approval process for solar installations across different jurisdictions and building code requirements. Metal roof solar brackets manufacturers also provide extensive training programs and technical support services to ensure that installers can properly deploy their products regardless of roof complexity or project scale. The compatibility solutions extend to integration with various solar panel manufacturers and system configurations, ensuring that mounting hardware does not limit design flexibility or system optimization opportunities. Advanced manufacturing capabilities allow metal roof solar brackets manufacturers to produce custom solutions efficiently without sacrificing quality or increasing lead times significantly. This comprehensive compatibility approach reduces project risks, eliminates installation delays, and provides solar installers with confidence that they can deliver reliable mounting solutions for any metal roof application they encounter in the field.