Structural Reliability as the Foundation of Project Feasibility

In high-wind regions, the performance of a single axis tracker is not determined solely by energy yield calculations, but by whether the structure can reliably withstand long-term environmental stress. For developers and EPCs evaluating project feasibility, structural reliability becomes a gating factor rather than an optimization variable. A tracker system that delivers higher annual output but introduces excessive structural risk can undermine financing, insurance approval, and long-term O&M stability.

From a manufacturing perspective, structural design capability is where differentiation truly emerges. High-wind sites expose weaknesses in pile sizing, torque tube stiffness, bearing tolerance, and connection detailing. A single axis tracker must maintain alignment accuracy under fluctuating loads while avoiding fatigue accumulation over decades of operation. This requires design methodologies that go beyond minimum code compliance and instead integrate wind tunnel data, site-specific load modeling, and conservative safety margins.

Another key consideration is how wind-induced deformation affects tracking accuracy and component wear. Excessive deflection not only increases mechanical stress but also accelerates wear on drive systems and bearings. Manufacturers with in-house structural engineering expertise can optimize section geometry, steel grade selection, and reinforcement strategies to balance strength, cost, and manufacturability.

In high-wind regions, reliability is not an abstract concept. It directly influences project bankability, insurance premiums, and long-term operating costs. For buyers comparing a single axis tracker against fixed-tilt structures, this reliability question often outweighs marginal energy yield differences.

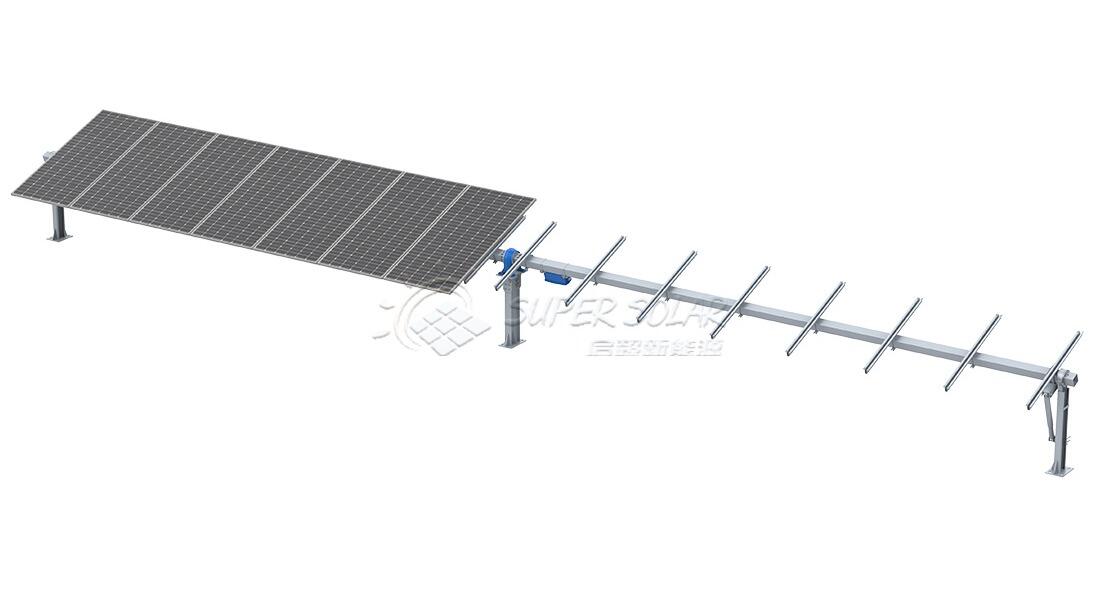

Wind Load Engineering and System Stability

![]()

High-wind environments demand a fundamentally different approach to wind load engineering. Rather than designing for peak gusts alone, a robust single axis tracker must address dynamic wind behavior, turbulence intensity, and directional variability across the site. These factors influence not only ultimate strength but also fatigue life and control system performance.

Site-Specific Wind Modeling Integration

Accurate wind modeling begins with proper interpretation of site data. Wind speed averages are insufficient; extreme gust events, directional frequency, and terrain roughness must all be considered. Advanced manufacturers integrate site wind data directly into structural calculations, allowing tracker geometry and foundation design to be tailored rather than standardized.

This approach reduces overdesign in moderate zones while ensuring sufficient safety margins in exposed areas. For developers, this means a single axis tracker layout that aligns with actual site conditions instead of generic assumptions. It also improves predictability during permitting and third-party engineering reviews.

Stow Strategy and Control Logic Design

Wind resilience is not only a structural issue but also a control strategy challenge. Stow positions, response timing, and redundancy all influence how a single axis tracker behaves during wind events. An effective stow strategy minimizes aerodynamic loads while maintaining system stability and avoiding resonance effects.

Control logic must account for rapid wind speed changes and sensor reliability. Manufacturers with integrated mechanical and control system design capabilities can ensure that stow commands are synchronized across arrays, reducing uneven load distribution. This is especially critical in large-scale projects where partial stow failures can propagate stress through shared components.

Dynamic Load Mitigation and Fatigue Management

Repeated wind cycling can be more damaging than rare extreme events. Fatigue accumulation in torque tubes, fasteners, and drive components is a primary failure risk in high-wind regions. A well-designed single axis tracker incorporates fatigue-resistant detailing, such as optimized weld profiles, reduced stress concentrations, and appropriate material selection.

By addressing fatigue at the design stage, manufacturers help project owners reduce long-term maintenance complexity and unexpected downtime. This is a key differentiator when comparing tracker solutions with similar upfront costs but different lifecycle performance.

Material Selection and Corrosion Protection in Harsh Environments

|

|

|

High-wind regions are often accompanied by other environmental challenges, including coastal exposure, high humidity, or temperature extremes. Material selection and corrosion protection therefore play a central role in ensuring the durability of a single axis tracker over its intended service life.

Structural Steel Grades and Section Optimization

Choosing the right steel grade is not simply a matter of strength. Ductility, weldability, and fatigue resistance all influence long-term performance. Manufacturers with strong material engineering expertise can select grades that provide consistent performance under cyclic loading while maintaining efficient manufacturing processes.

Section optimization is equally important. By refining cross-sectional geometry, it is possible to increase stiffness without proportionally increasing weight. This reduces wind-induced deflection while controlling material costs, a balance that directly impacts project economics.

Coating Systems and Anti-Corrosion Strategies

Corrosion can significantly reduce structural capacity over time, particularly in high-wind areas where abrasive particles and moisture accelerate degradation. A comprehensive anti-corrosion strategy includes appropriate surface preparation, coating selection, and quality control during application.

Hot-dip galvanizing, advanced zinc-aluminum coatings, or multi-layer protective systems may be selected based on site conditions. For a single axis tracker deployed in coastal or desert wind zones, these choices can determine whether the system maintains structural integrity over 25 years or requires premature refurbishment.

Fasteners, Bearings, and Secondary Components

Secondary components are often overlooked, yet they are critical to overall system reliability. Fasteners must resist loosening under vibration, bearings must tolerate misalignment and dust ingress, and seals must maintain performance under temperature fluctuations.

A manufacturer-focused design approach ensures that all components are evaluated as part of an integrated system. This reduces weak points that could compromise the performance of the entire single axis tracker array.

Installation Tolerance and Long-Term Maintenance Considerations

In high-wind regions, installation accuracy and maintenance accessibility are as important as initial design strength. A tracker system that is difficult to install correctly or maintain efficiently introduces operational risk that can erode projected returns.

Foundation Design and Pile Interaction

Foundation behavior under wind loading is highly site-dependent. Soil variability, pile embedment depth, and installation method all affect system stability. Manufacturers with experience in diverse geotechnical conditions can provide guidance on pile design that aligns with both structural requirements and installation practicality.

Proper tolerance management during installation ensures that the single axis tracker operates within its intended mechanical limits. Misalignment can increase drive loads and reduce system lifespan, particularly under wind-induced movement.

Ease of Inspection and Component Replacement

High-wind sites often require more frequent inspections, especially after extreme weather events. A well-designed tracker system facilitates access to critical components without extensive disassembly. This reduces inspection time and improves response speed when issues arise.

Maintenance complexity is a common concern when comparing a single axis tracker to fixed-tilt systems. By simplifying component interfaces and standardizing parts, manufacturers can mitigate this concern and make tracker systems more attractive for challenging environments.

Lifecycle Cost Management

While initial CAPEX is important, lifecycle cost ultimately determines project profitability. Design choices that reduce maintenance frequency, minimize replacement parts, and extend service intervals provide tangible financial benefits. In high-wind regions, these considerations often outweigh small differences in upfront pricing.

Evaluating Tracker Versus Fixed-Tilt Structures in High-Wind Regions

![]()

One of the most common questions from project developers is whether a single axis tracker is suitable for a given high-wind site, or whether fixed-tilt structures offer a safer alternative. The answer depends on a balanced evaluation of energy yield, structural risk, and long-term operational stability.

A single axis tracker typically delivers higher annual energy production by optimizing module orientation throughout the day. In many cases, this increased yield can offset higher structural and control system complexity. However, if the tracker design does not adequately address wind loads, the risk profile may become unacceptable.

Fixed-tilt systems, while simpler, may require heavier structures or reduced tilt angles in high-wind areas, which can limit energy output. When properly engineered, a tracker system can achieve a favorable balance between yield and reliability, particularly when site-specific wind data is integrated from the outset.

For decision-makers, the key is not whether trackers are inherently riskier, but whether the selected single axis tracker has been designed and manufactured with high-wind conditions as a core design input rather than an afterthought.

Manufacturer Capabilities as a Decision Criterion

In high-wind projects, the choice of manufacturer is often as important as the choice of technology. Structural design capability, testing experience, and quality control systems directly influence project outcomes.

Manufacturers that invest in wind engineering expertise, advanced simulation tools, and rigorous validation testing are better positioned to support complex sites. Their ability to adapt designs based on site data, rather than offering fixed configurations, provides additional confidence to developers and investors.

Equally important is communication during the early project phase. A manufacturer that can review site location and wind data and translate it into a practical tracker layout proposal adds value beyond equipment supply. This collaborative approach reduces design iterations and accelerates project timelines.

For buyers evaluating multiple suppliers, these capabilities often distinguish a reliable partner from a commodity provider.![]()

FAQ

How does wind data influence single axis tracker design decisions

Wind data informs load calculations, stow strategy, foundation sizing, and component selection. Accurate site-specific data allows manufacturers to tailor the tracker system to actual conditions rather than relying on conservative generic assumptions.

Is maintenance more complex for a single axis tracker in high-wind regions

Maintenance requirements depend on design quality and component selection. Well-engineered systems with fatigue-resistant detailing and accessible components can maintain manageable maintenance levels even in high-wind environments.

Can a single axis tracker be adapted if wind conditions are more severe than expected

Design flexibility varies by manufacturer. Systems designed with modular components and adaptable control logic are better suited to adjustments based on updated wind assessments or operational experience.

What information should be shared with a manufacturer during early evaluation

Providing site location, historical wind data, terrain characteristics, and preliminary layout constraints enables manufacturers to develop a more accurate tracker layout proposal and assess structural suitability.

Send us your site location and wind data to get a tracker layout proposal tailored to your project conditions.

Table of Contents

- Structural Reliability as the Foundation of Project Feasibility

- Wind Load Engineering and System Stability

- Material Selection and Corrosion Protection in Harsh Environments

- Installation Tolerance and Long-Term Maintenance Considerations

- Evaluating Tracker Versus Fixed-Tilt Structures in High-Wind Regions

- Manufacturer Capabilities as a Decision Criterion

- FAQ

- How does wind data influence single axis tracker design decisions

- Is maintenance more complex for a single axis tracker in high-wind regions

- Can a single axis tracker be adapted if wind conditions are more severe than expected

- What information should be shared with a manufacturer during early evaluation