Solar Mounting Systems

Contact Us

- Building A06, Jimei Software Park, Xiamen, China

- +86-592-6683155

- [email protected]

This selection guide focuses on helping installers, EPCs, and distributors choose the most appropriate mounting system based on project conditions, rather than promoting any specific product.

When designing a metal roof solar PV system, one of the most common engineering and procurement decisions is whether to use a solar mini rail system or a full rail mounting system.

For EPC contractors, installers, and distributors, this choice directly affects structural safety, installation efficiency, project cost, and long-term reliability. This article provides a professional, B2B-focused comparison to help you select the right solution for different project scenarios.

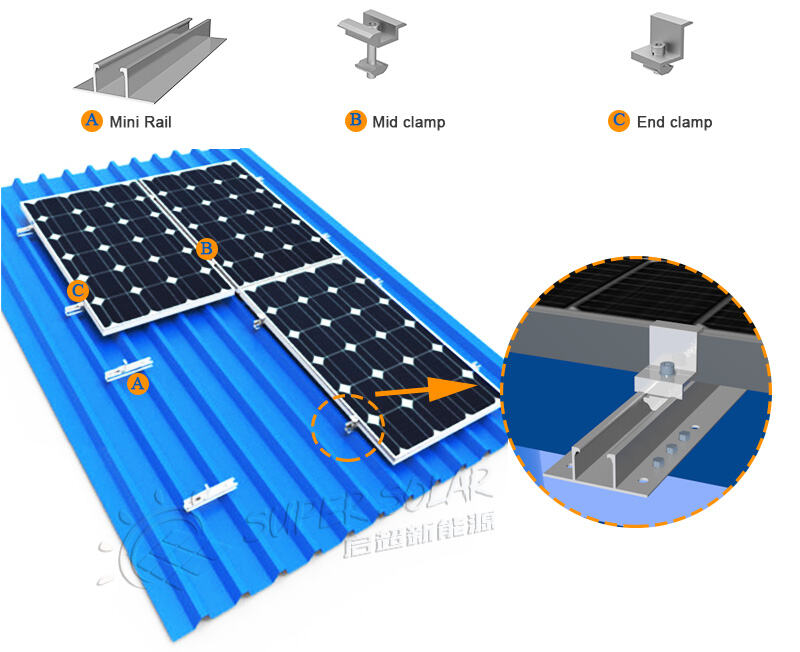

A solar mini rail is a short aluminum rail segment fixed directly to a metal roof sheet using self-drilling screws and sealing washers. Solar modules are mounted on these short rails rather than on long continuous rails.

Key characteristics:

Designed for trapezoidal or corrugated metal roofs

Penetrating installation

Reduced material usage

Faster installation compared to full rail systems

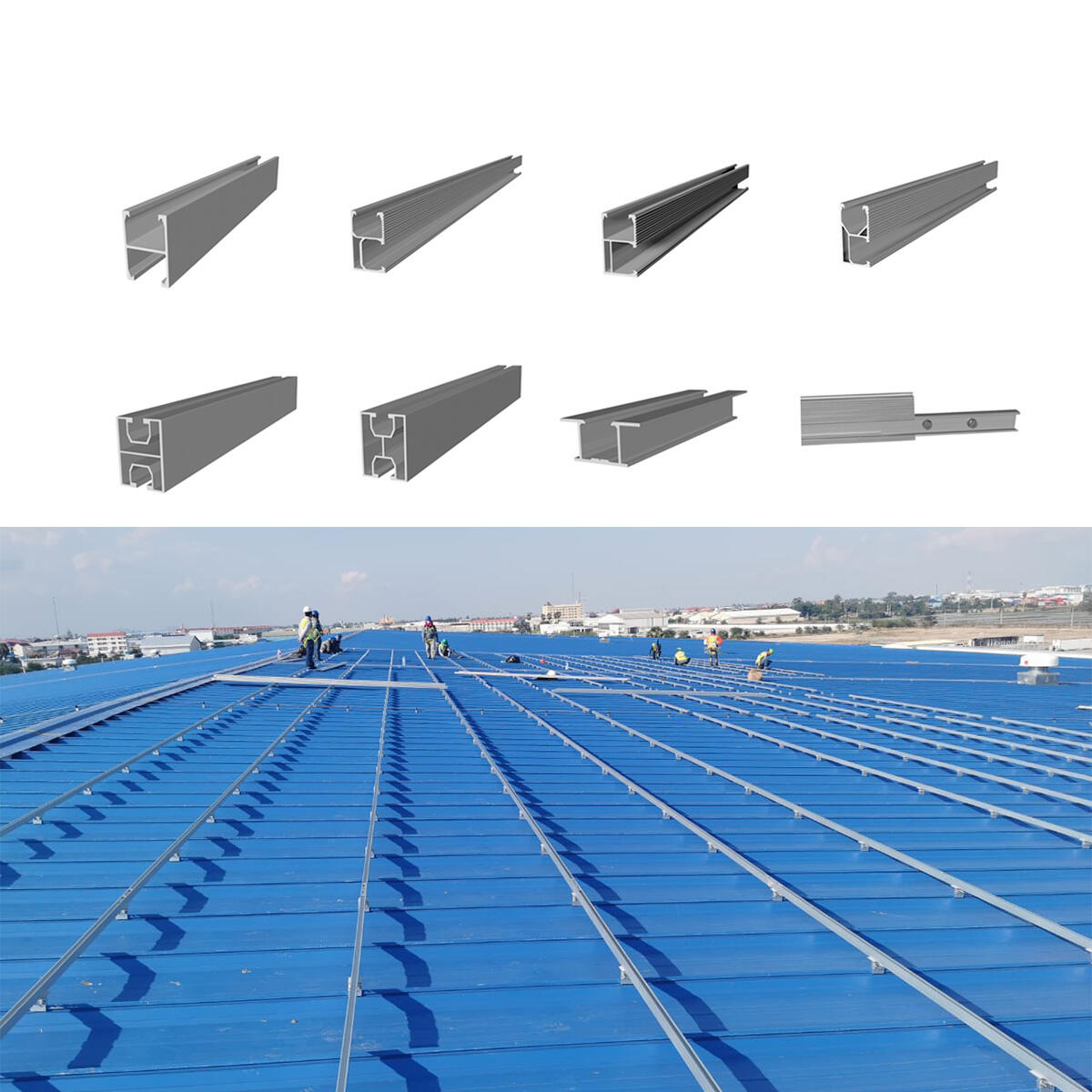

A full rail system uses continuous aluminum rails running across the roof, supported by roof attachments or brackets. Solar panels are clamped along these rails.

Key characteristics:

Widely used across residential, commercial, and industrial projects

Higher structural tolerance

Flexible layout adjustment

Compatible with a wider range of roof conditions

| Comparison Item | Solar Mini Rail | Full Rail System |

|---|---|---|

| Material usage | Low | Higher |

| Installation speed | Very fast | Moderate |

| Structural tolerance | Lower | Higher |

| Roof load distribution | Concentrated | More evenly distributed |

| Engineering flexibility | Limited | High |

| Transport & storage | Compact | Bulkier |

| Typical project size | Small–medium | Medium–large |

Solar mini rails significantly reduce aluminum consumption, which lowers material cost, transportation volume, and storage requirements.

With fewer components and no long rail alignment, installers can complete projects faster, reducing labor costs per kilowatt installed.

Short rail lengths naturally minimize thermal expansion effects compared to continuous rail systems.

Mini rails work best on standard trapezoidal metal roofs with consistent purlin spacing and good sheet strength.

Mini rail systems transfer more load directly to the roof sheet and fasteners, requiring careful evaluation of roof conditions.

Layout tolerance is smaller. Incorrect positioning can affect load distribution and module alignment.

Solar mini rails are not recommended for standing seam roofs or roofs with unknown structural performance.

Continuous rails distribute loads more evenly, making them suitable for high wind, high snow, or complex roof zones.

Full rail systems allow installers to adjust module positions more easily during installation.

They can be adapted to a wider range of roof types and project conditions.

Higher material and transport costs

Longer installation time

Increased system weight

The project uses standard trapezoidal metal roofs

Roof sheet strength is verified

Speed and cost efficiency are priorities

Project size is small to medium

Roof conditions are complex or variable

The project is located in high wind or snow load zones

Greater structural redundancy is required

Long-term adjustability is important

Before selecting either system, professional buyers should evaluate:

Local wind and snow load requirements

Roof manufacturer warranty conditions

Fastener pull-out strength

Availability of structural calculation reports

Installation team experience

There is no universally "better" solution between solar mini rail and full rail systems. The optimal choice depends on roof structure, environmental loads, installation conditions, and project risk tolerance.

For EPC contractors and installers, understanding these differences helps avoid installation risks, cost overruns, and long-term performance issues.

Yes, when properly engineered and installed on suitable metal roofs. Structural calculations are recommended, especially in high wind or snow load regions.

Full rail systems distribute loads along continuous rails, reducing dependence on individual fasteners and roof sheet strength.

No. Mini rails are best for simple metal roof projects. Full rail systems are preferred for complex or high-risk environments.

Solar mini rails usually offer lower total cost due to reduced materials and faster installation, assuming roof conditions are suitable.

Both systems can achieve 25-year service life when properly designed. Full rail systems generally provide higher redundancy.