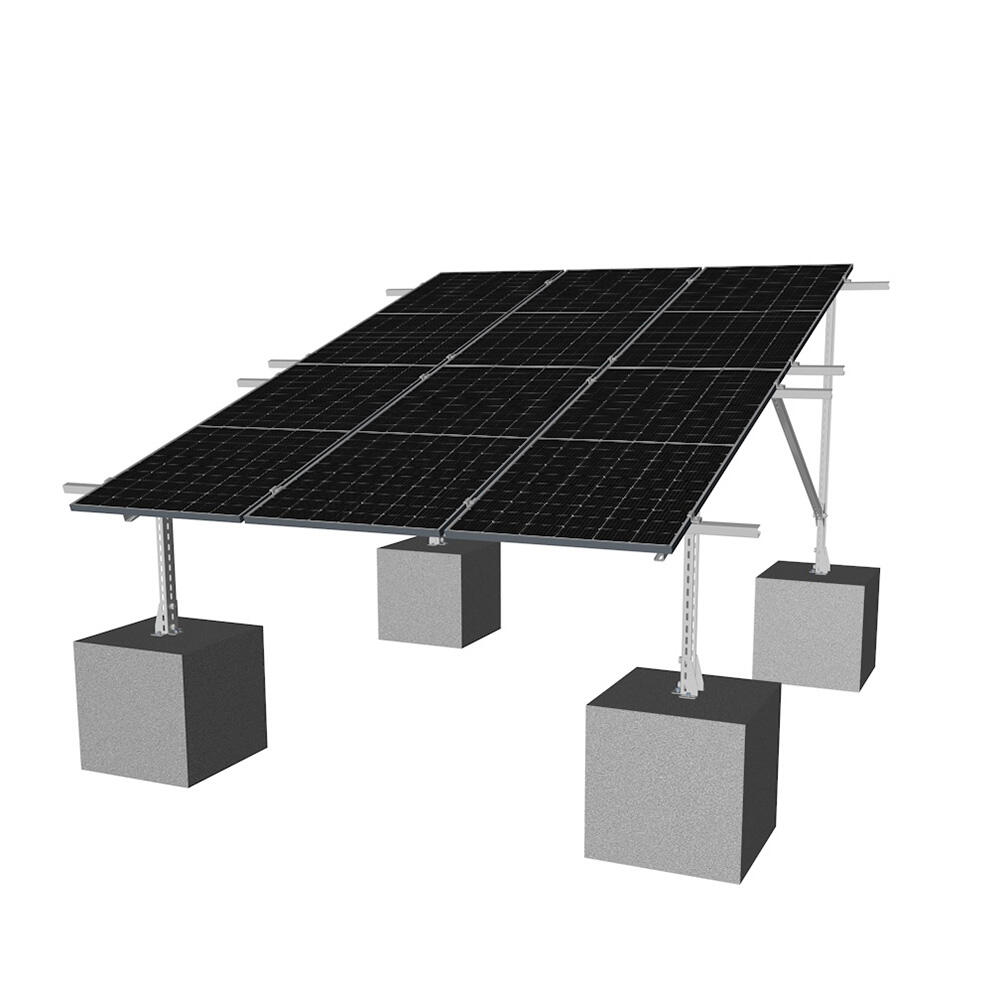

ZAM coated steel solar rack ground mount

Our steel solar rack ground mount system is built with high-strength ZAM (Zinc-Aluminum-Magnesium) coated steel, offering exceptional corrosion resistance and long-term durability. Ideal for utility-scale and commercial ground-mounted solar projects, it ensures fast installation, structural reliability, and lower maintenance costs.

> ZAM Coated Steel Structure

> Strong & Durable

> Efficient Installation

> Flexible Configuration

> Environment-Ready

> Compliant with International Standards

- Overview

- Recommended Products

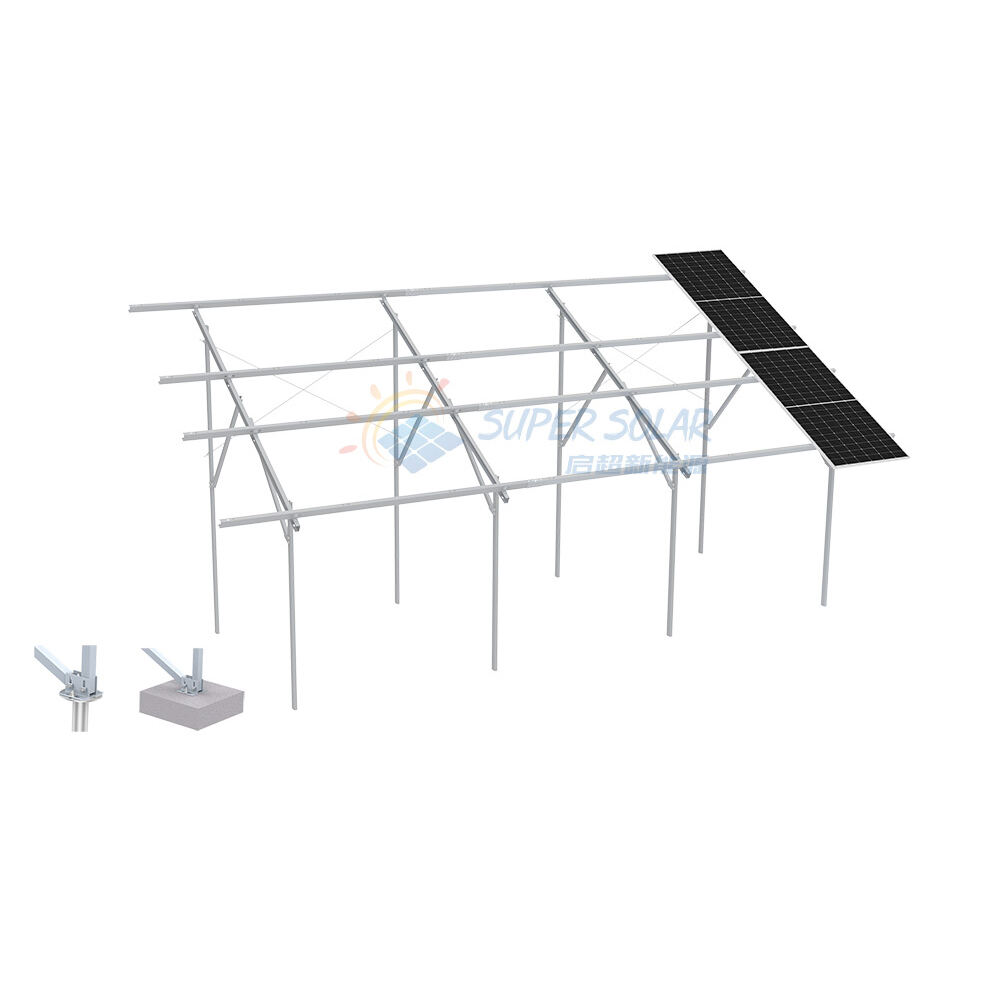

ZAM coated steel solar rack ground mount

ZAM coated steel is a Zn-Al-Mg ternary alloy coatingsteel. This chemical composition has been chosen toprovide the optimum levels of corrosion resistance, which is about 3 to 5 times comparing with HDG steel. This kind of steel permits all the conventional processing operations possible with standard HDG steel. Inaddition to these many benefits, ZAM coated steel hasa lower friction coefficient which remains stablethroughout forming operations to get a better solarmounting structure.

| ||

|

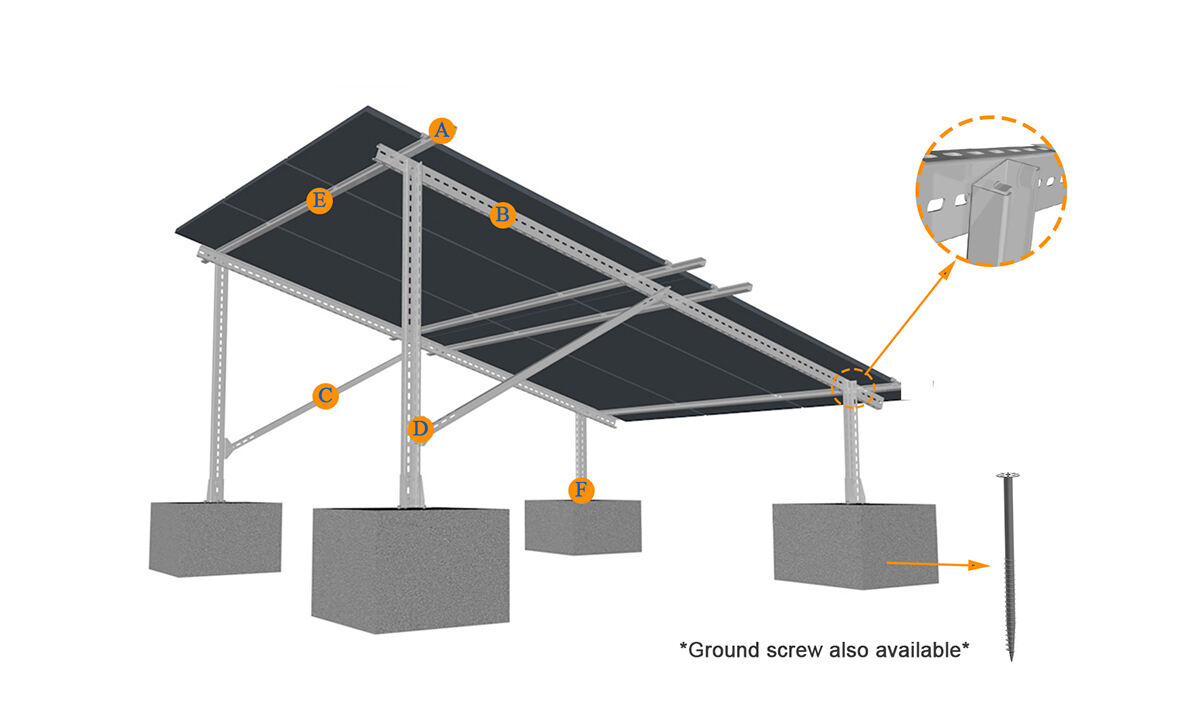

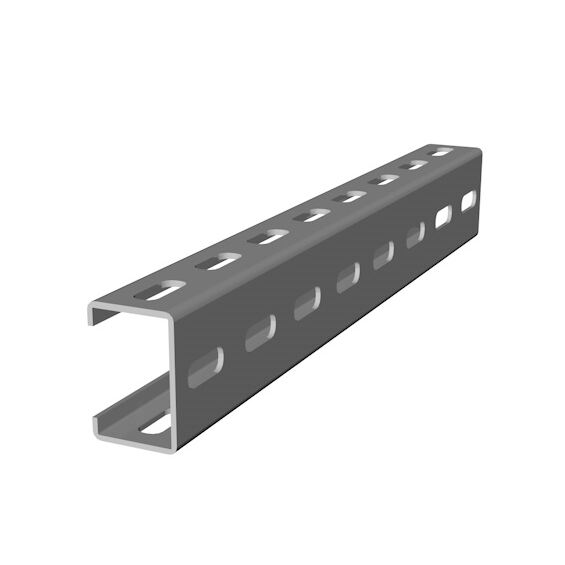

A. Rail |

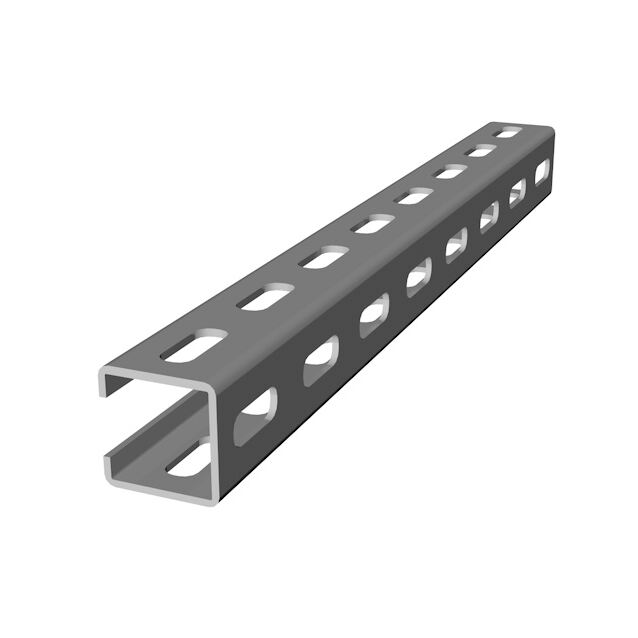

B. Beam |

C. Pile / Brace |

|

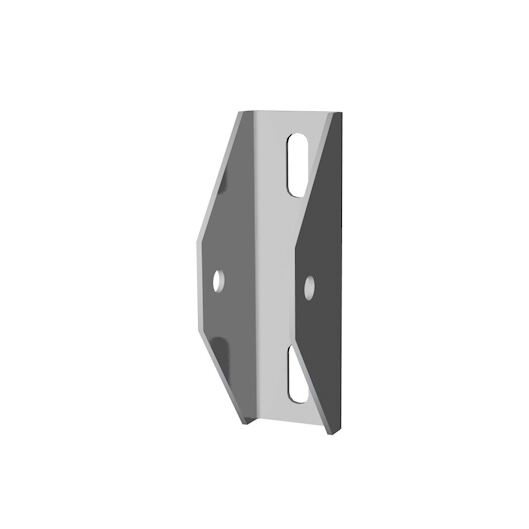

D. Triangle connector |

E. Rail splice |

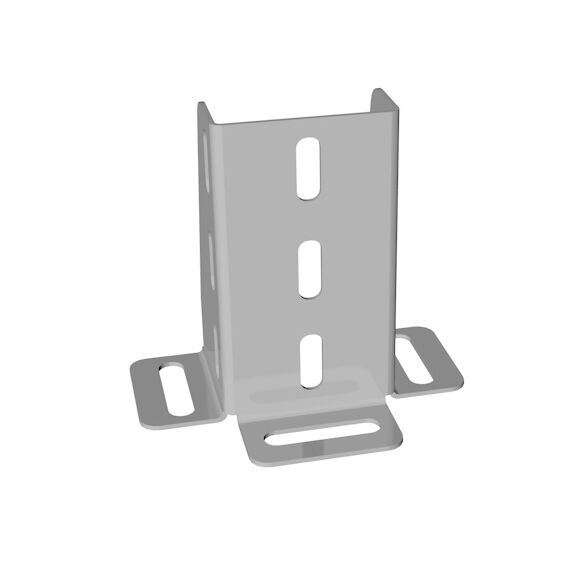

F. Base |

Technical Datasheet

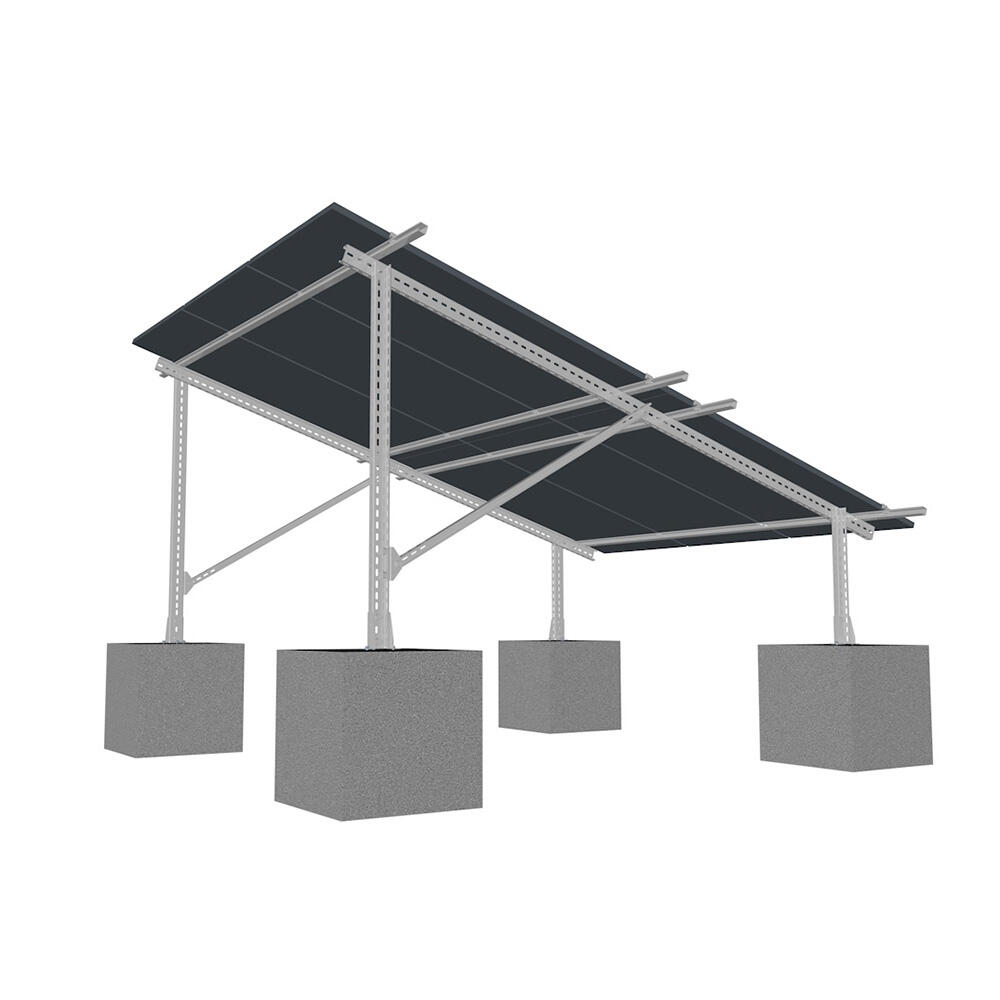

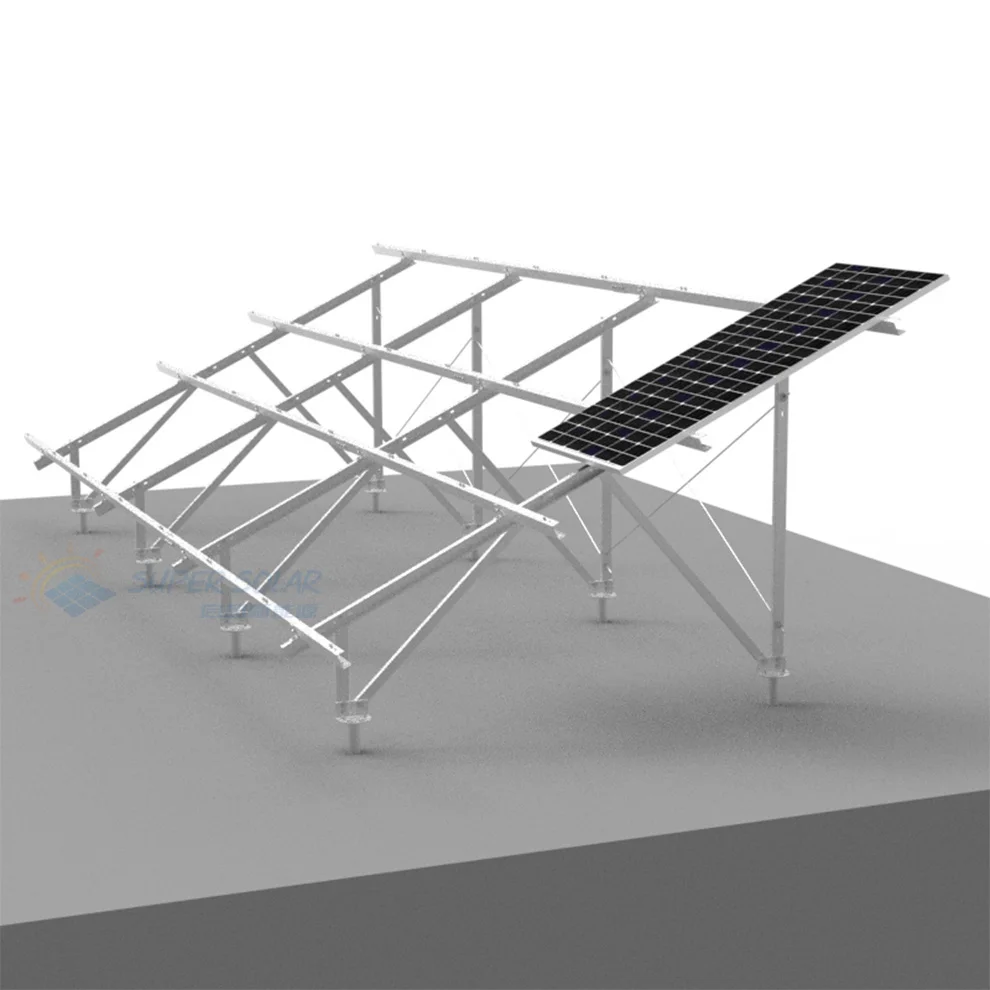

| Application | Flat roof or open field |

| Material | ZAM coated steel. |

| Panel Type | Framed & Frameless |

| Wind Load | Up to 60m/s |

| Snow Load | Up to1.0 KN/m² |

| Panel Orientation | Landscape or Portrait |

| Tilt Angle | 0-45 deg |

| Certificate | ISO/CE |

| Warranty | 12 Years |

| Service life | 25 Years |

Features & Benefits

· ZAM Coated Steel Structure: Superior corrosion resistance—up to 3–10 times better than traditional galvanized steel.

· Strong & Durable: Engineered to support high wind and snow loads, suitable for various terrains.

· Efficient Installation: Modular design with pre-punched holes and pre-cut components for reduced on-site labor.

· Flexible Configuration: Supports both portrait and landscape panel layouts, adaptable to single or double post foundations.

· Environment-Ready: Perfect for desert, coastal, or high-humidity environments where traditional materials fail.

· Compliant with International Standards: Designed to meet CE, ISO, and other global engineering requirements.

Project Case

We Support Your Projects

· Free System Design: Customized mounting solution based on site conditions and customer requirements.

· One-Stop Supply: Complete kits including steel racks, fasteners, and grounding accessories.

· Fast Production & Shipping: Quick lead time with professional export packaging.

· European Warehouse Support: Shorter delivery times and reduced costs for EU partners.

· OEM & Branding Services: Custom labeling, packaging, and component stamping available.

· Expert B2B Support Team: Fast response for RFQs, technical consultations, and post-sale service.