Installation Versatility and Compatibility

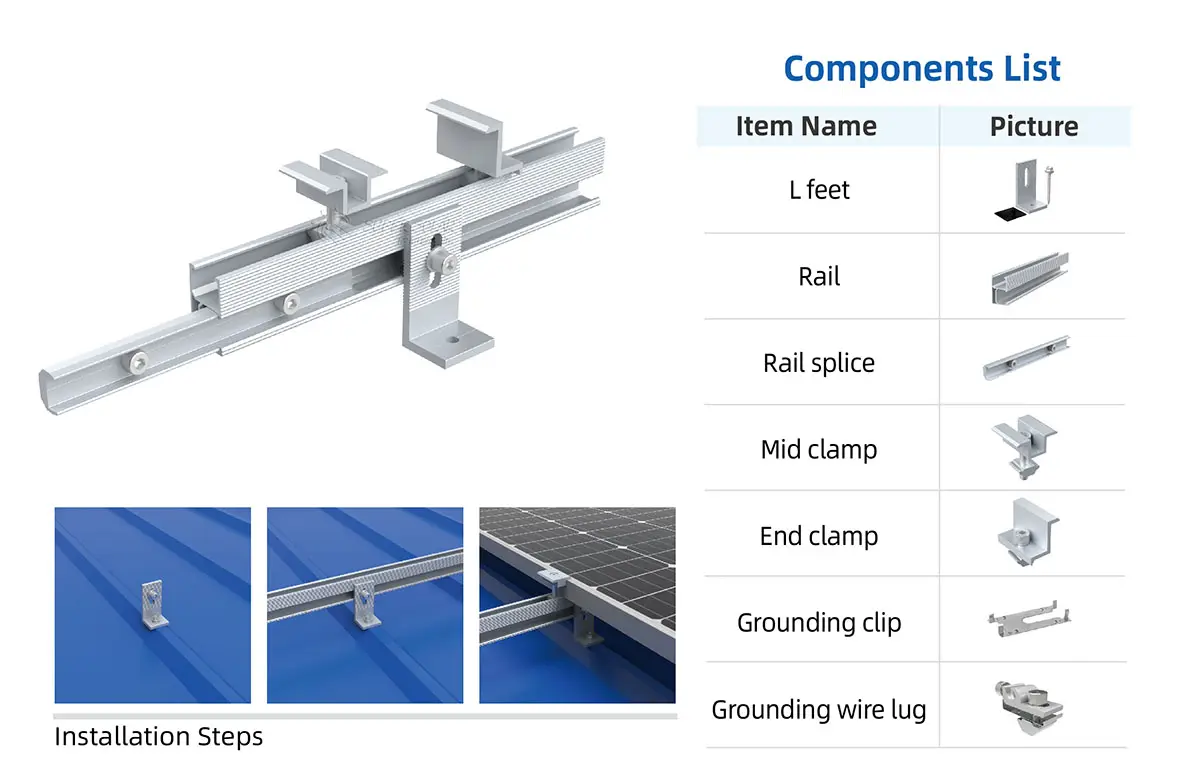

The installation versatility and compatibility features of adjustable tilt solar panel mounts provide unmatched flexibility for diverse project requirements, accommodating various building types, roof configurations, and ground-mounting scenarios with equal effectiveness. This adaptability stems from modular design principles that allow customization for specific site conditions while maintaining structural integrity and optimal performance characteristics. Roof compatibility spans multiple surface types including asphalt shingles, metal roofing, tile installations, membrane systems, and concrete structures, with specialized mounting hardware designed for each application to ensure weatherproof integration. The adjustable framework accommodates different panel sizes and weights, supporting both standard residential panels and larger commercial modules without requiring separate mounting solutions for mixed installations. Ground-mounting versatility enables installation on various foundation types including concrete pads, helical piles, ballasted systems, and pole mounts, providing options for different soil conditions and site restrictions. The universal rail system accepts panels from all major manufacturers, eliminating compatibility concerns and allowing system expansion or panel replacement with different brands as technology evolves. Installation height flexibility ranges from low-profile residential applications to elevated commercial installations, with telescoping components that adjust to specific clearance requirements while maintaining optimal tilt functionality. Site gradient accommodation allows installation on sloped terrain without extensive site preparation, with leveling mechanisms that compensate for uneven surfaces up to 15-degree variations. The modular expansion capability enables phased installation approaches, allowing property owners to start with smaller systems and expand capacity over time without replacing existing mounting infrastructure. Electrical integration features include pre-installed wire management systems, grounding provisions, and conduit attachments that streamline electrical connections while maintaining code compliance and safety standards. Maintenance access design ensures technicians can service all components safely and efficiently, with strategically positioned access points and tool-free adjustment mechanisms that reduce service time and costs. The compatibility extends to tracking system integration, allowing future upgrades to automated positioning systems without complete reinstallation, protecting the initial investment while enabling technology advancement adoption.