china solar mounting for metal roof manufacturers

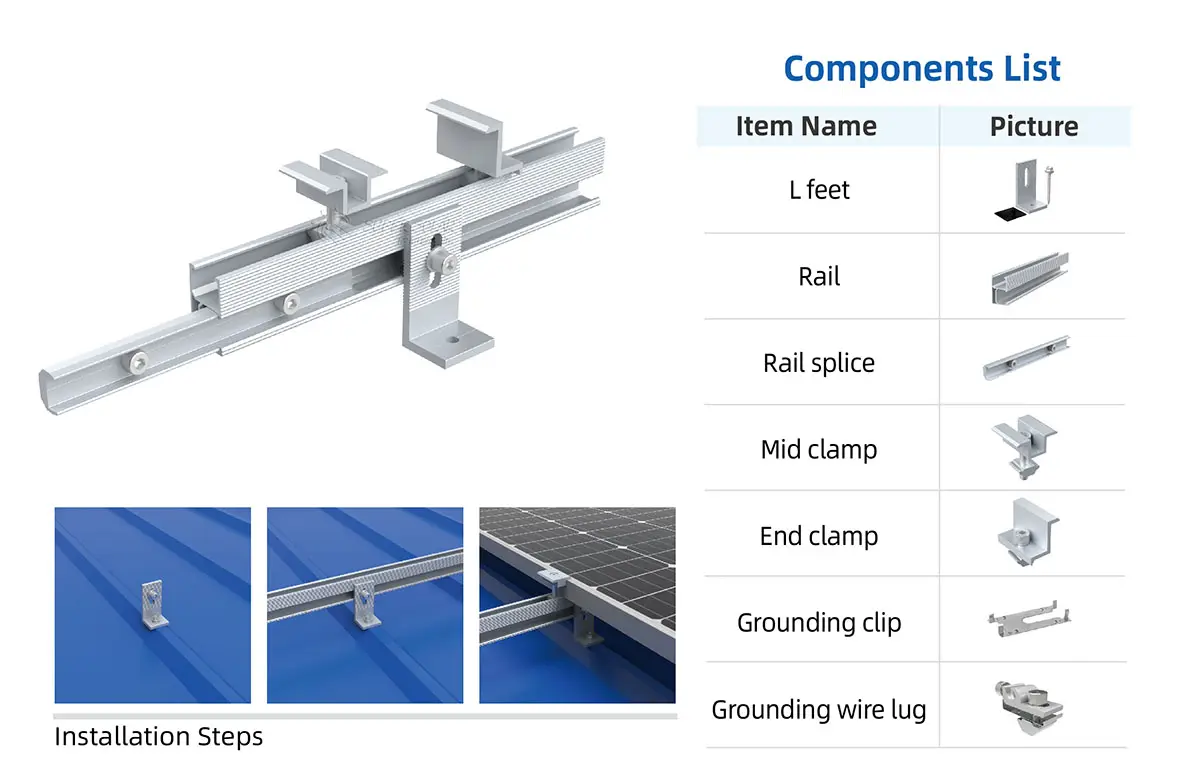

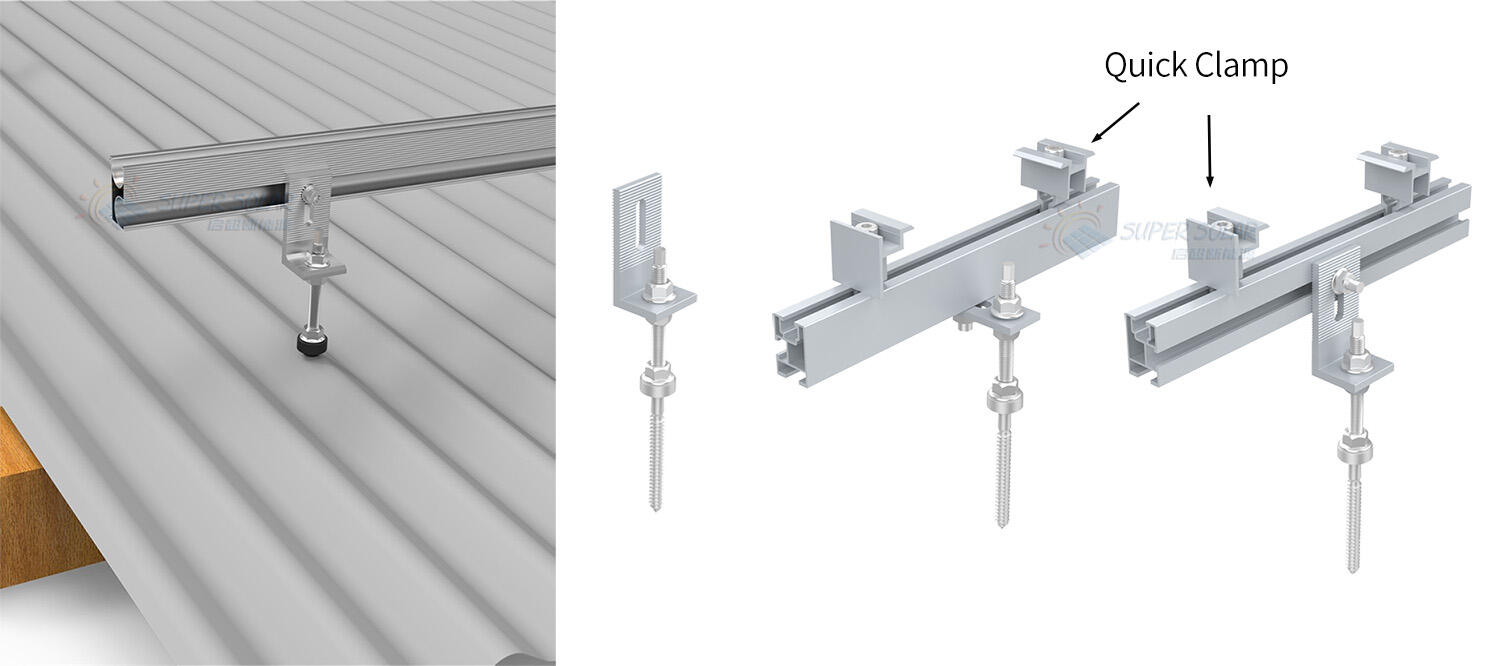

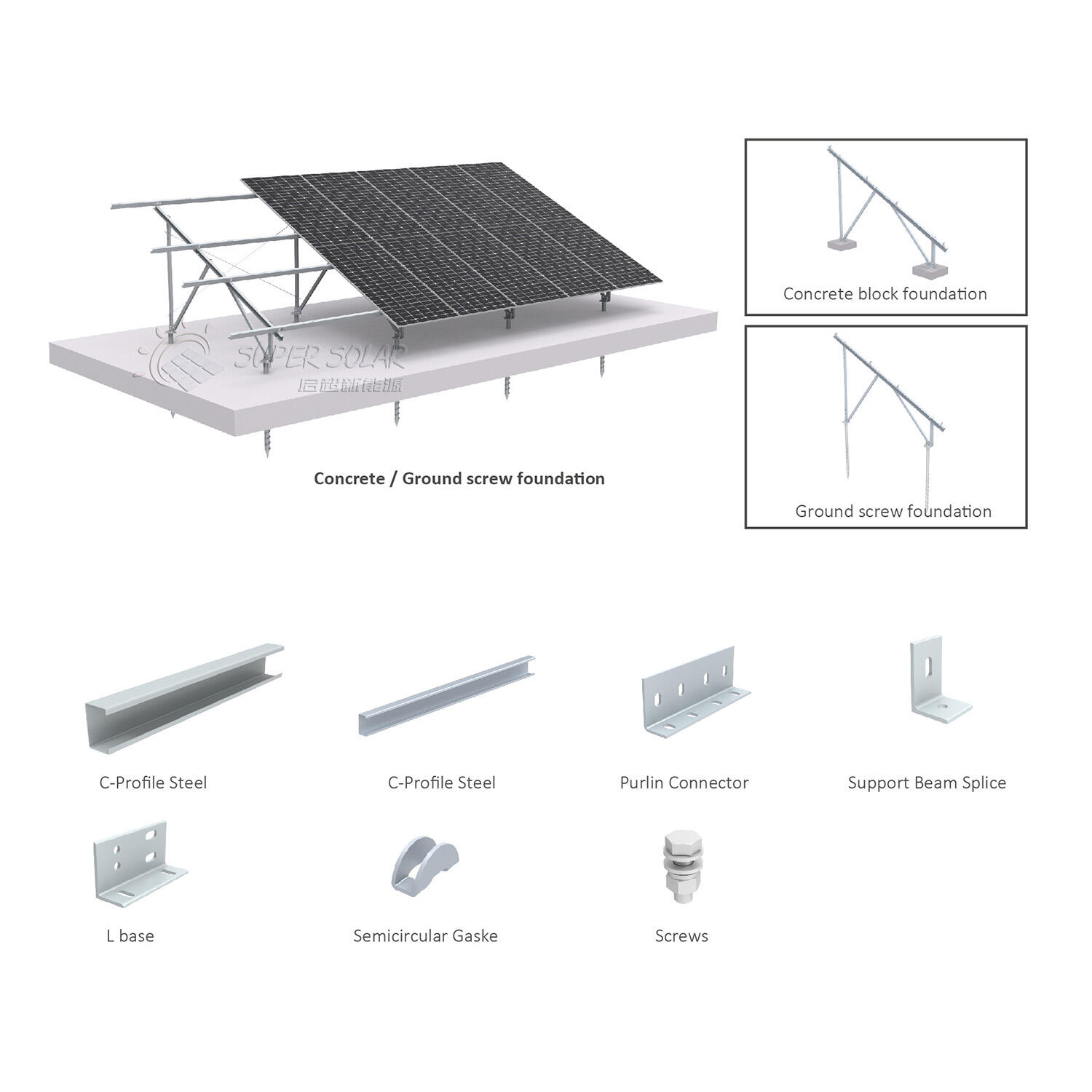

China solar mounting for metal roof manufacturers represent a revolutionary advancement in renewable energy infrastructure, delivering comprehensive solutions that seamlessly integrate photovoltaic systems with various metal roofing configurations. These sophisticated mounting systems are engineered to provide optimal performance while maintaining structural integrity and weather resistance across diverse climatic conditions. The primary function of china solar mounting for metal roof manufacturers involves creating secure, durable connections between solar panels and metal roofing surfaces without compromising the roof's protective capabilities or aesthetic appeal. Advanced technological features include precision-engineered clamps, adjustable rail systems, and corrosion-resistant materials specifically designed for metal roof applications. The mounting systems utilize high-grade aluminum alloy construction combined with stainless steel hardware to ensure longevity and reliability in challenging environmental conditions. Innovative design elements incorporate thermal expansion accommodation, wind load distribution, and waterproof sealing technologies that protect both the solar installation and underlying roofing structure. Applications span residential, commercial, and industrial sectors where metal roofing is prevalent, including warehouses, manufacturing facilities, agricultural buildings, and modern residential constructions. The systems accommodate various metal roof profiles including standing seam, corrugated, and trapezoidal configurations, providing versatility across different architectural requirements. Installation processes are streamlined through modular components that reduce labor time and complexity while ensuring consistent quality outcomes. Quality control measures implemented by china solar mounting for metal roof manufacturers include rigorous testing protocols for structural load capacity, weather resistance, and electrical safety standards. These mounting solutions support both crystalline silicon and thin-film solar technologies, offering flexibility in panel selection based on specific project requirements and performance objectives.