china solar panel mounting bracket

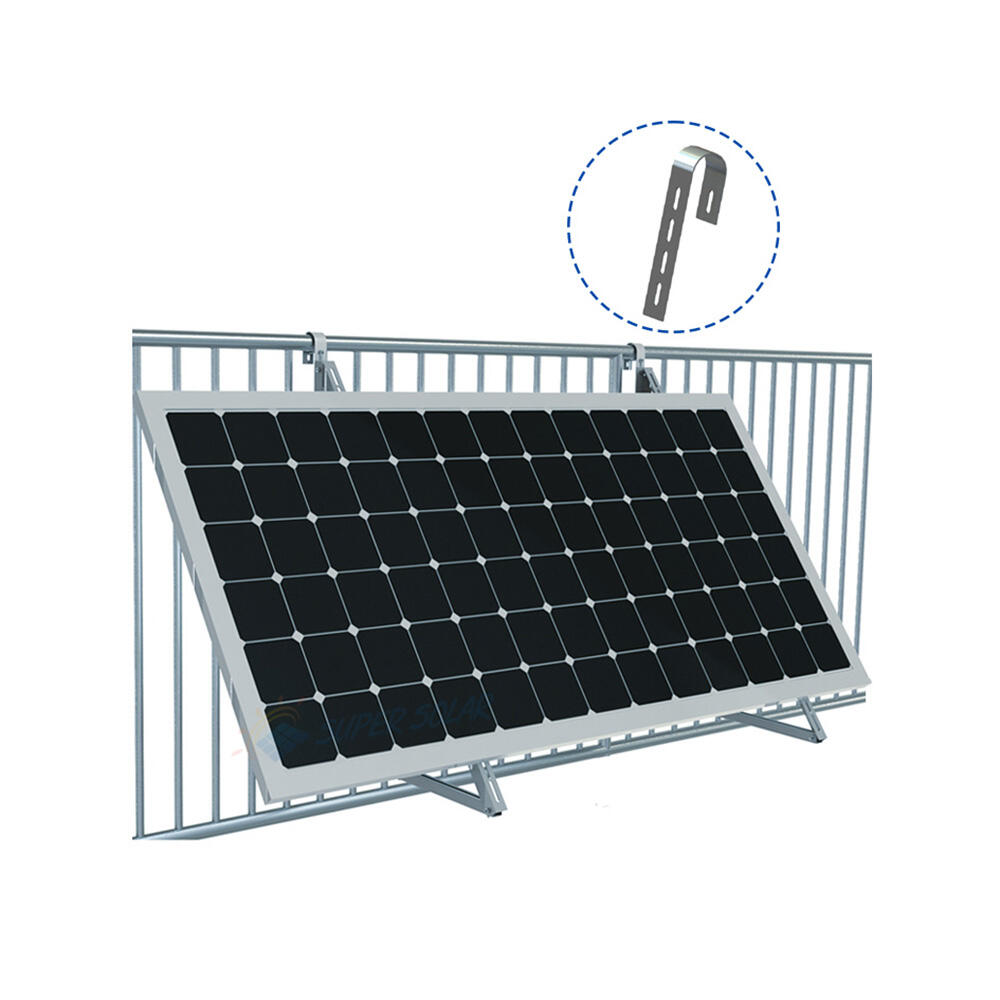

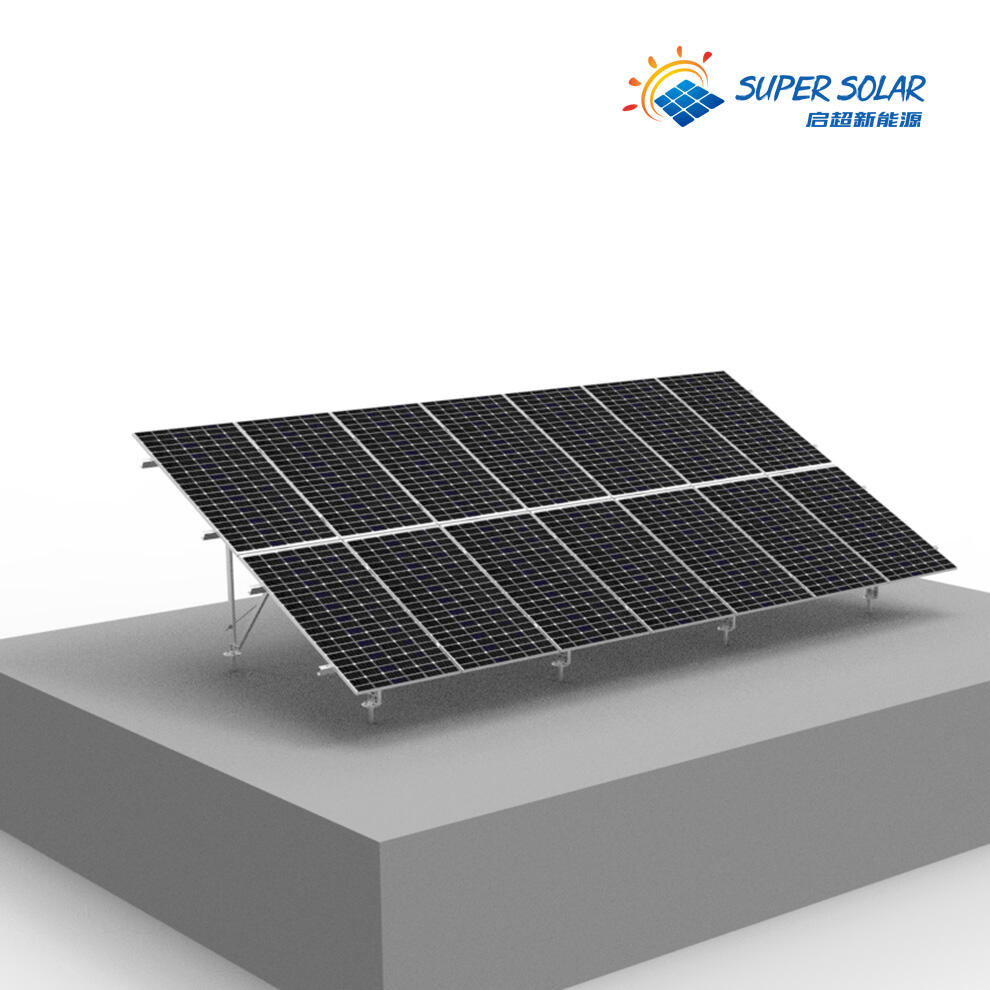

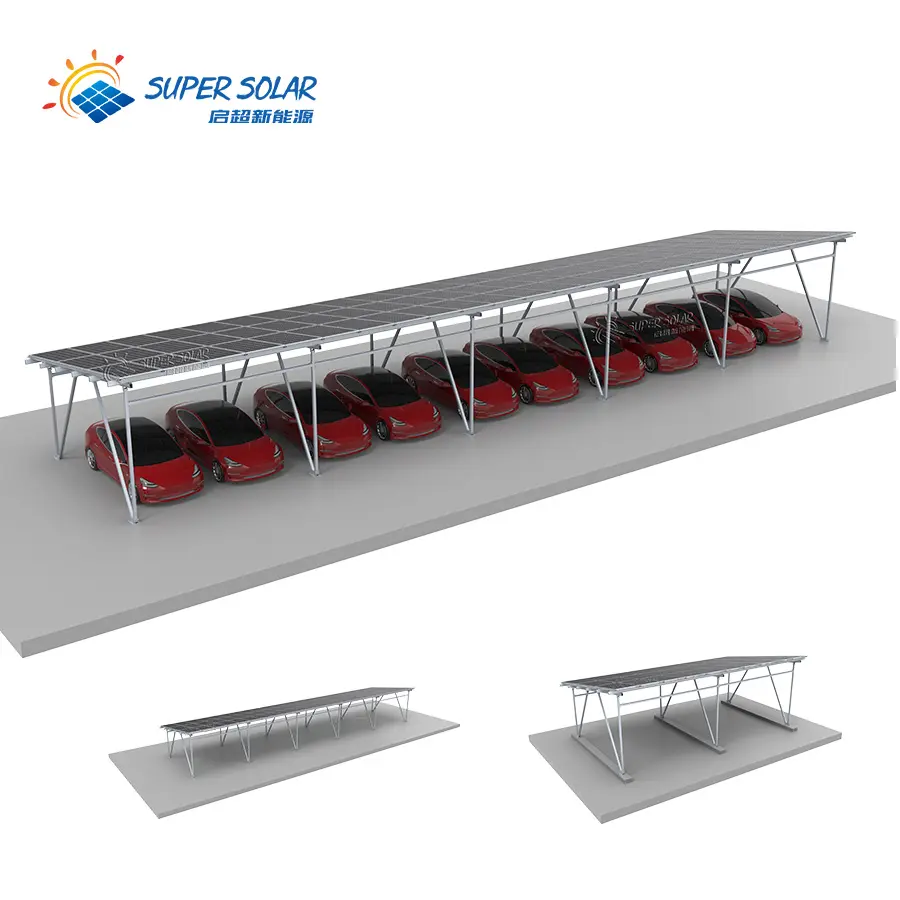

China solar panel mounting brackets represent a critical infrastructure component in the global renewable energy revolution, serving as the foundation for secure and efficient photovoltaic installations worldwide. These mounting systems are engineered to provide robust structural support for solar panels while ensuring optimal positioning for maximum energy capture. The china solar panel mounting bracket industry has emerged as a dominant force in the international market, combining advanced engineering principles with cost-effective manufacturing processes. These brackets function as the mechanical interface between solar panels and various installation surfaces, including rooftops, ground-mounted structures, and specialized solar farms. The primary function of a china solar panel mounting bracket involves creating a stable platform that can withstand environmental stresses such as wind loads, snow accumulation, and seismic activity while maintaining proper panel alignment. Modern mounting bracket systems incorporate sophisticated design features including adjustable tilt angles, corrosion-resistant materials, and modular configurations that accommodate different panel sizes and installation requirements. The technological foundation of these brackets relies on precision-engineered aluminum alloys and galvanized steel components that deliver exceptional strength-to-weight ratios. Chinese manufacturers have pioneered innovative rail systems, clamps, and fastening mechanisms that streamline installation processes while ensuring long-term reliability. These mounting solutions feature advanced drainage channels, integrated grounding systems, and aerodynamic profiles that minimize wind resistance. The applications for china solar panel mounting brackets span residential rooftops, commercial buildings, utility-scale solar farms, and specialized installations such as floating solar arrays and agrivoltaic systems. The versatility of these mounting systems enables deployment across diverse geographical regions and climate conditions, making them essential components for global solar energy expansion initiatives.