ground solar mounting system factory

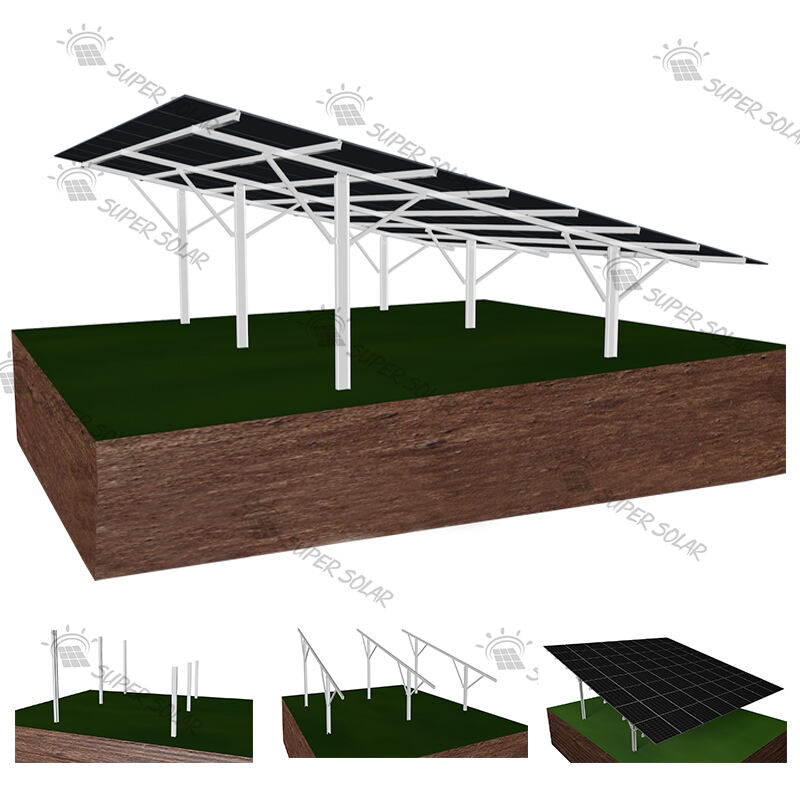

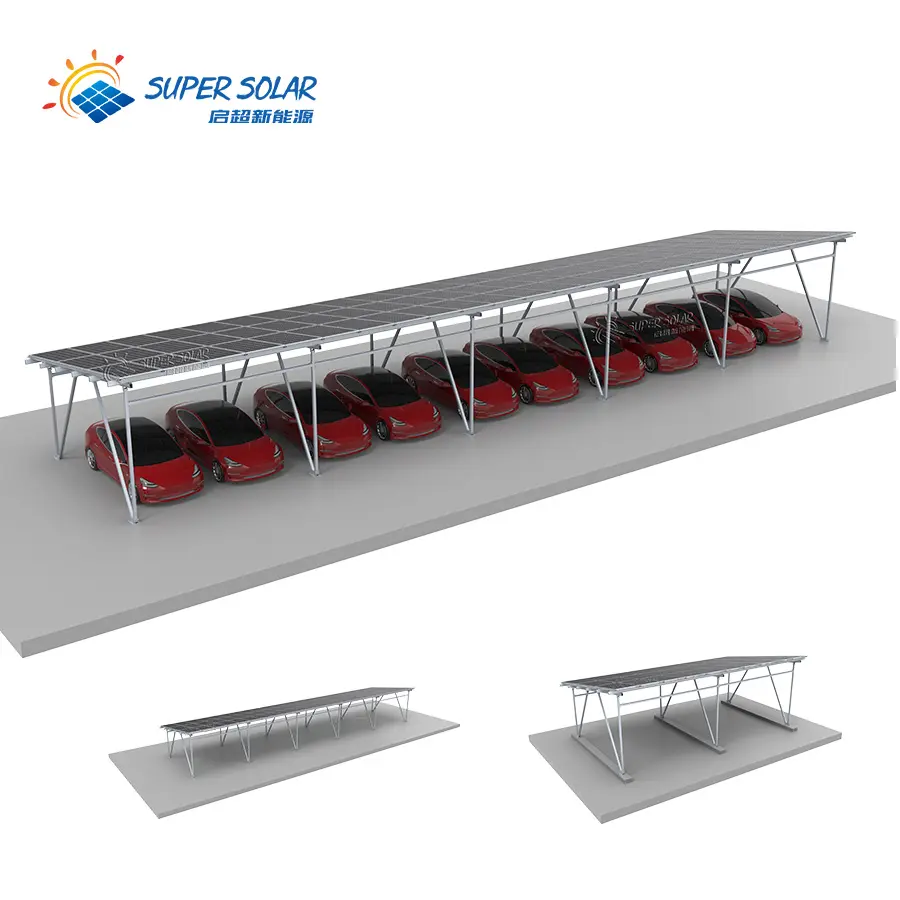

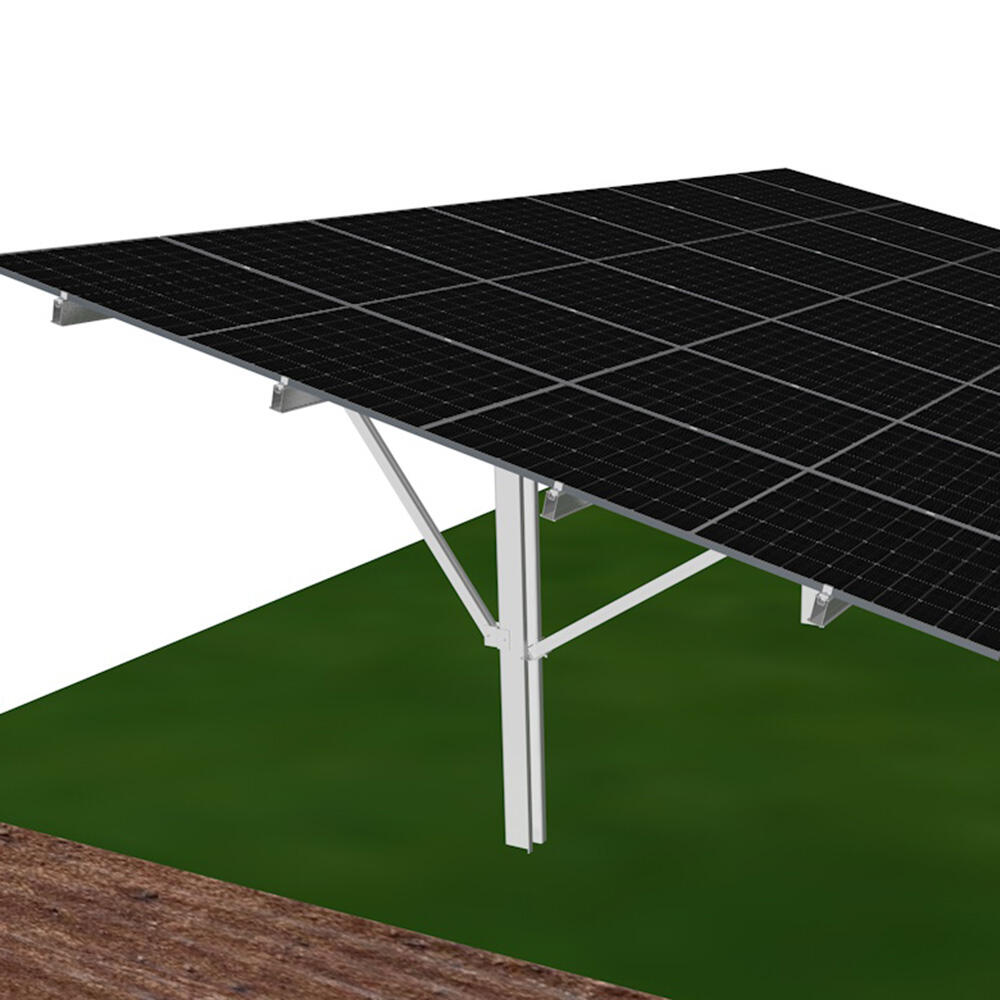

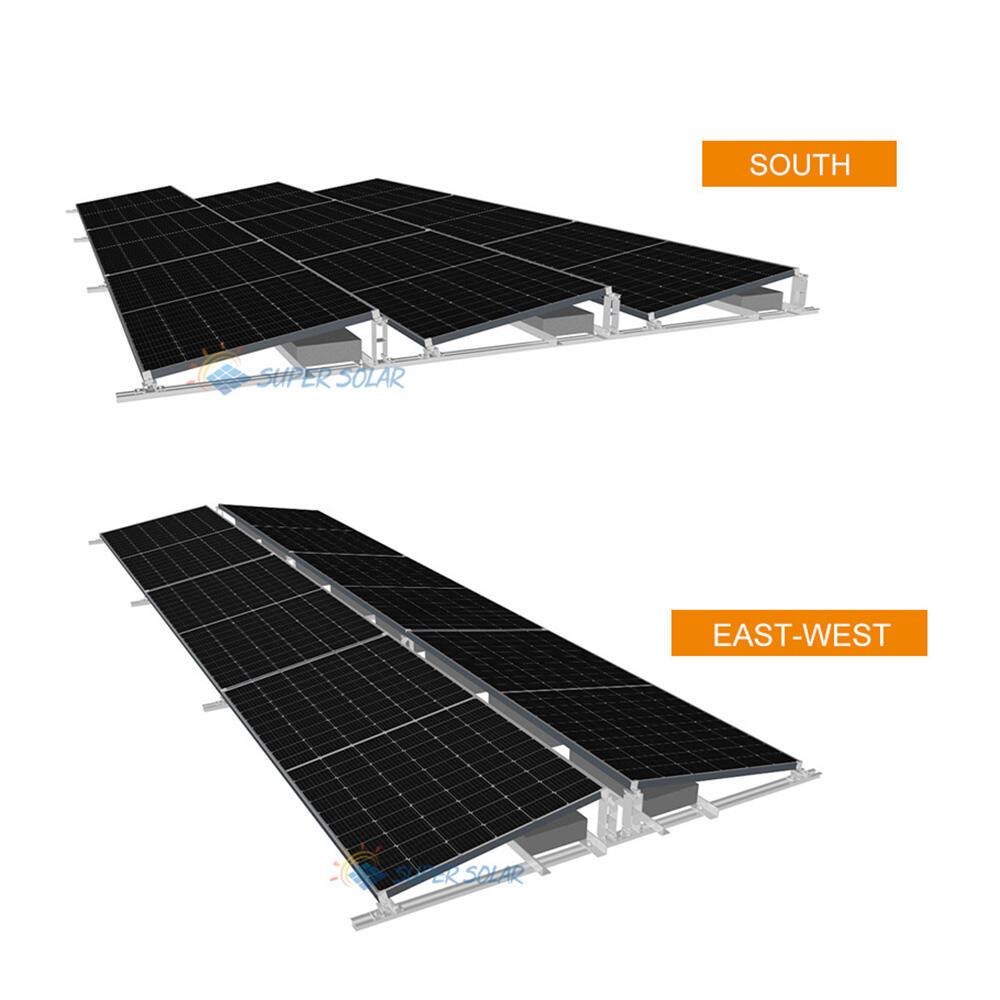

A ground solar mounting system factory represents a specialized manufacturing facility dedicated to producing robust and efficient mounting solutions for photovoltaic installations on level terrain. These factories serve as the backbone of the renewable energy infrastructure, manufacturing critical components that secure solar panels to the ground while maximizing energy capture efficiency. The ground solar mounting system factory operates through sophisticated production lines that combine precision engineering with advanced metallurgy to create durable, weather-resistant mounting structures. The primary function of a ground solar mounting system factory involves designing, fabricating, and assembling various mounting configurations including fixed-tilt systems, single-axis tracking systems, and dual-axis tracking systems. These facilities employ cutting-edge manufacturing technologies such as automated welding stations, computer-controlled cutting machines, and powder coating lines to ensure consistent quality and dimensional accuracy. The technological features of a modern ground solar mounting system factory include advanced CAD software for custom design solutions, robotic assembly systems for high-volume production, and comprehensive quality control laboratories for material testing and performance validation. These factories typically maintain extensive research and development departments that continuously innovate mounting solutions to accommodate different soil conditions, wind loads, and seismic requirements. Applications of products from a ground solar mounting system factory span across utility-scale solar farms, commercial installations, and large residential projects where ground-mounted arrays are preferred over rooftop installations. The factory's output includes pre-engineered mounting kits, custom-fabricated support structures, and specialized hardware components that ensure reliable long-term performance in diverse environmental conditions. Modern ground solar mounting system factory operations emphasize sustainability through recycling programs, energy-efficient manufacturing processes, and the use of eco-friendly materials wherever possible.