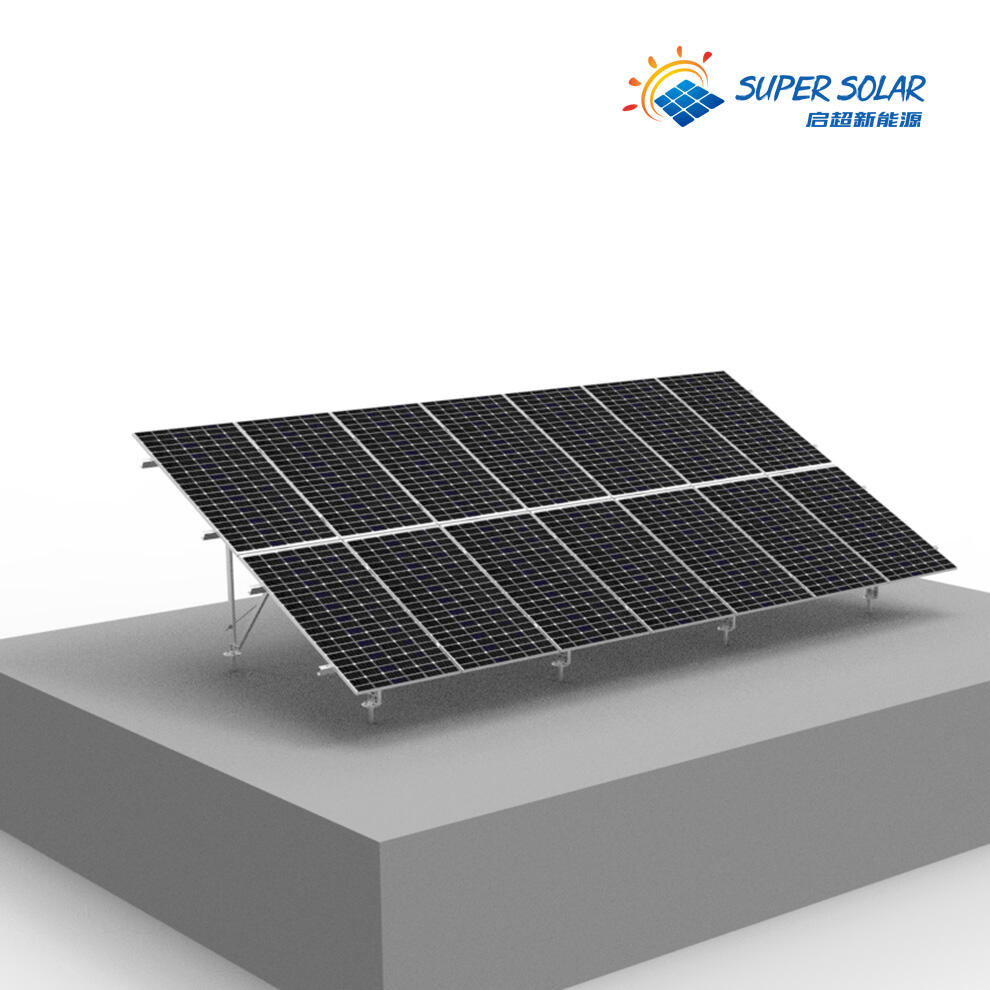

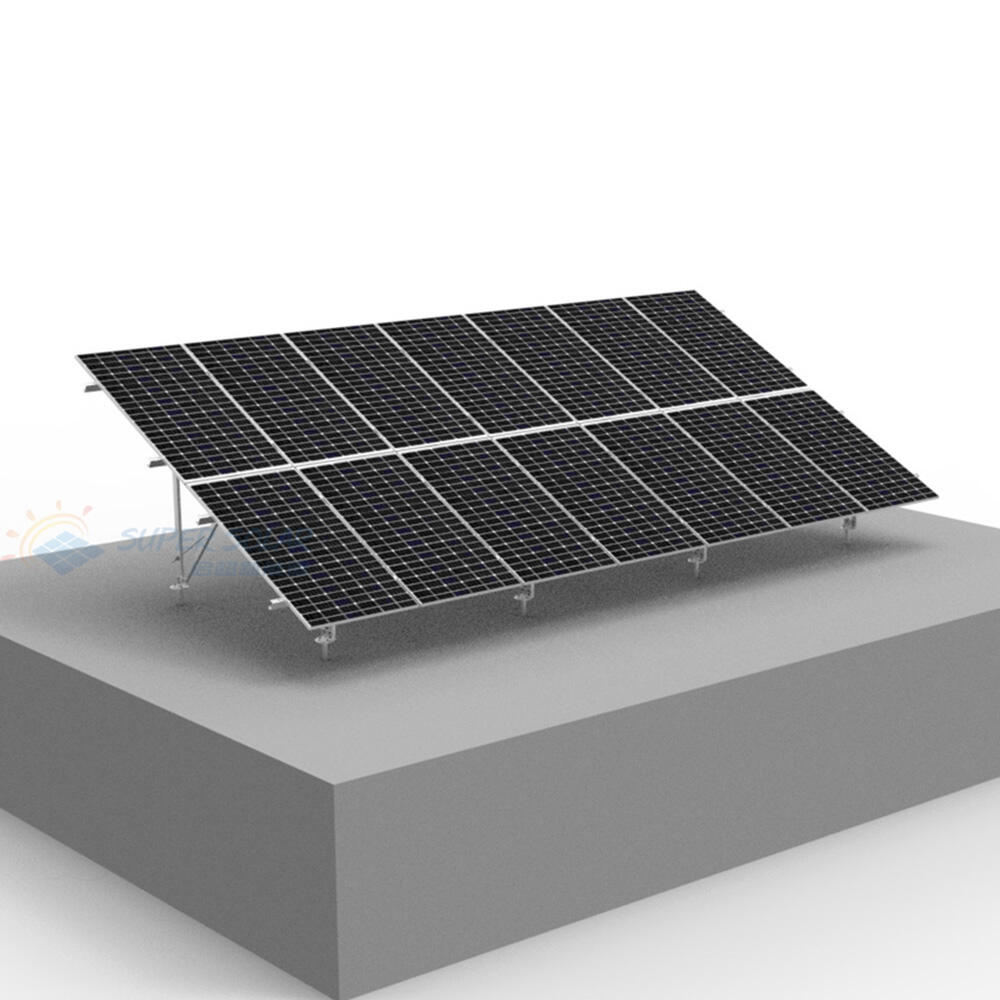

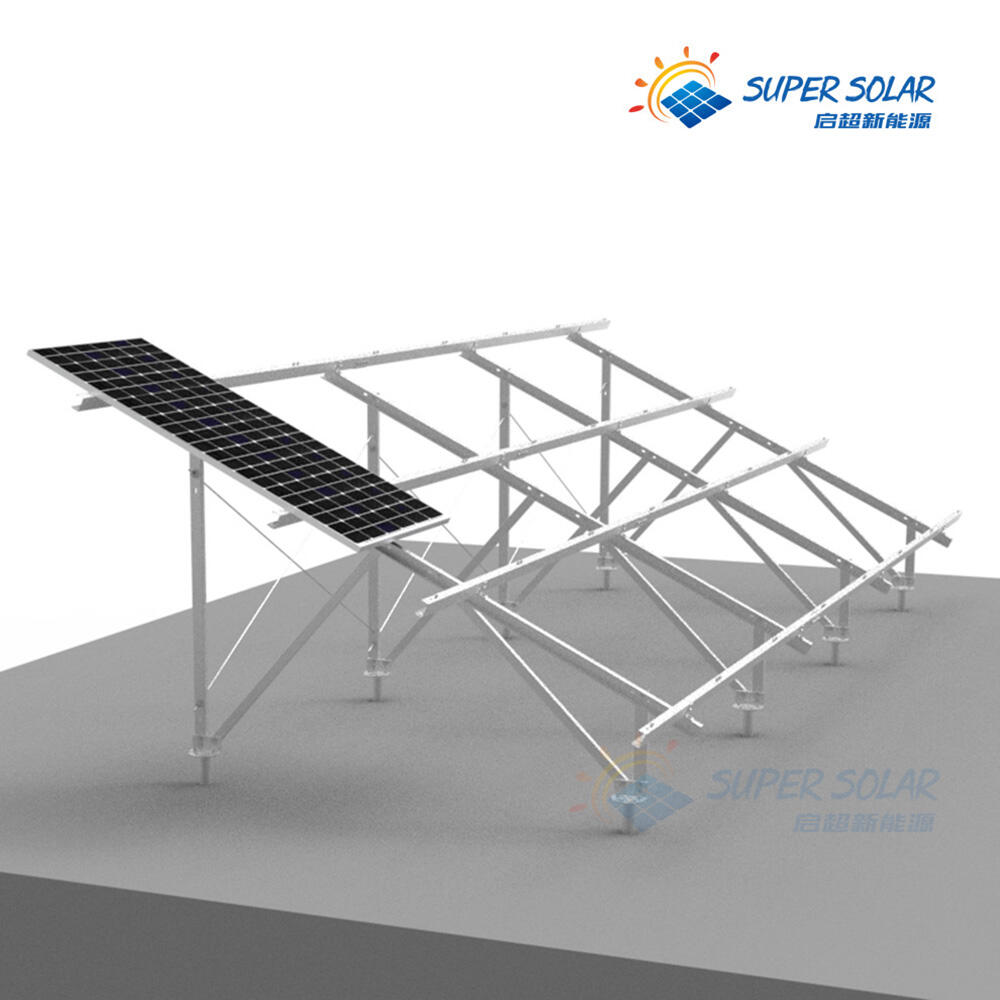

solar ground mounting structure chinese factory

Solar ground mounting structure chinese factory represents a cornerstone of the renewable energy manufacturing sector, producing essential infrastructure components that enable large-scale photovoltaic installations worldwide. These specialized facilities focus on designing, engineering, and manufacturing robust mounting systems that secure solar panels to ground-based foundations across diverse terrains and environmental conditions. The primary function of a solar ground mounting structure chinese factory involves creating comprehensive mounting solutions that include aluminum rails, steel brackets, foundation systems, tracking mechanisms, and associated hardware components. These factories employ advanced manufacturing processes, incorporating precision engineering techniques and quality control measures to ensure products meet international standards and certifications. The technological features of modern solar ground mounting structure chinese factory operations include automated production lines, computer-aided design systems, and sophisticated testing equipment that validates structural integrity and weather resistance. Manufacturing capabilities typically encompass multiple product categories, including fixed-tilt mounting systems, single-axis tracking systems, dual-axis tracking systems, and customized solutions for specific project requirements. The production process integrates lean manufacturing principles, utilizing state-of-the-art machinery for cutting, welding, forming, and finishing operations. Quality assurance protocols ensure each component meets rigorous performance standards for wind load resistance, snow load capacity, and corrosion protection. Applications for products from solar ground mounting structure chinese factory span utility-scale solar farms, commercial installations, industrial facilities, and large residential developments. These mounting systems accommodate various panel technologies, including crystalline silicon and thin-film modules, while providing flexibility for different installation angles and configurations. The factory operations support global deployment of renewable energy projects by delivering cost-effective, reliable mounting solutions that facilitate efficient installation processes and long-term performance optimization across diverse geographical locations and climate conditions.