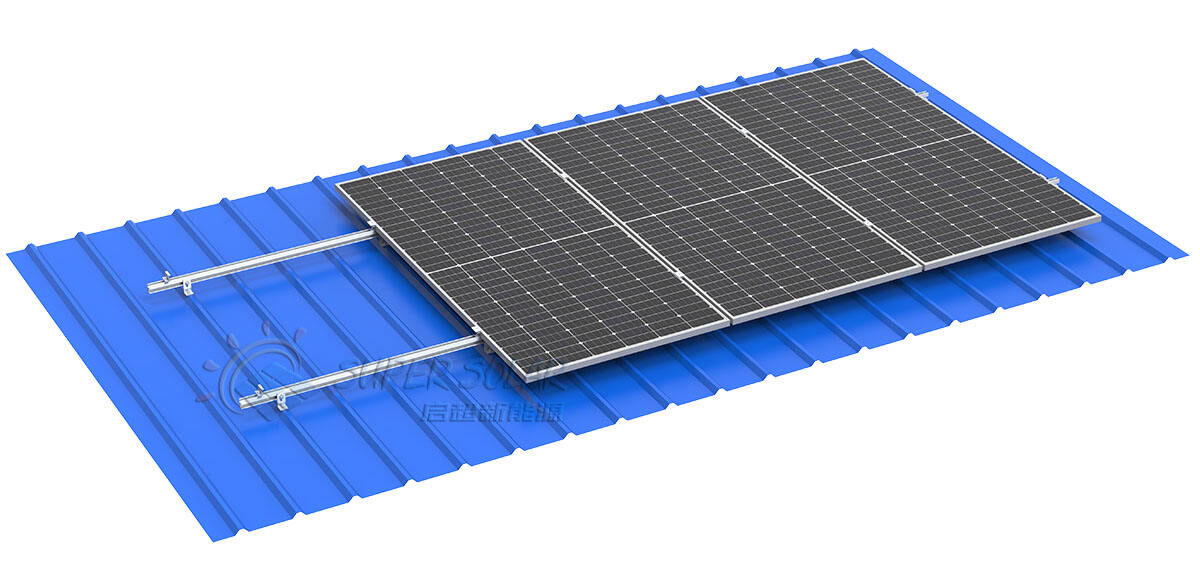

latest design metal roof solar brackets

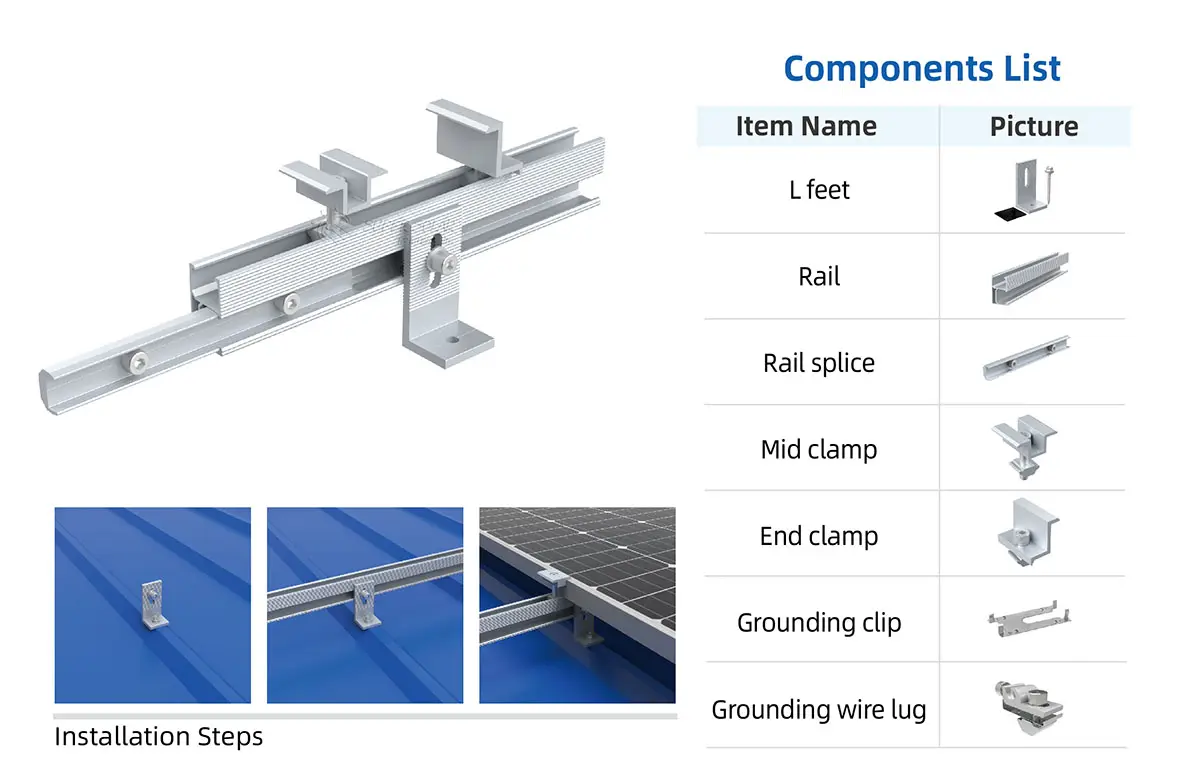

The latest design metal roof solar brackets represent a revolutionary advancement in photovoltaic mounting technology, specifically engineered to optimize solar panel installations on various metal roofing systems. These cutting-edge mounting solutions incorporate advanced engineering principles and premium materials to deliver unparalleled performance, durability, and installation efficiency. The primary function of these innovative brackets centers on providing secure, weather-resistant attachment points that maintain the structural integrity of both the roofing system and solar array while maximizing energy production potential. Modern metal roof solar brackets feature sophisticated clamping mechanisms that eliminate roof penetrations, preserving the waterproof barrier and extending roof lifespan significantly. The technological framework includes corrosion-resistant aluminum alloys and stainless steel components, ensuring decades of reliable service in harsh environmental conditions. These mounting systems accommodate various metal roof profiles including standing seam, corrugated, and ribbed configurations, offering versatility for diverse architectural applications. Advanced grounding pathways are integrated directly into the bracket design, streamlining electrical connections and reducing installation complexity. The latest design metal roof solar brackets incorporate pre-assembled components that dramatically reduce field assembly time while maintaining precise alignment tolerances. Thermal expansion compensation features prevent stress concentrations that could compromise long-term performance. Applications span residential, commercial, and industrial sectors, with scalable solutions supporting installations ranging from small residential arrays to massive commercial solar farms. The aerodynamic profile minimizes wind uplift forces while optimizing drainage patterns to prevent water accumulation. Quality assurance protocols ensure each bracket meets stringent industry standards for structural loading, environmental exposure, and electrical safety. These mounting systems facilitate faster project completion timelines while reducing overall installation costs through improved labor efficiency and reduced material waste.