mounting systems for solar panels

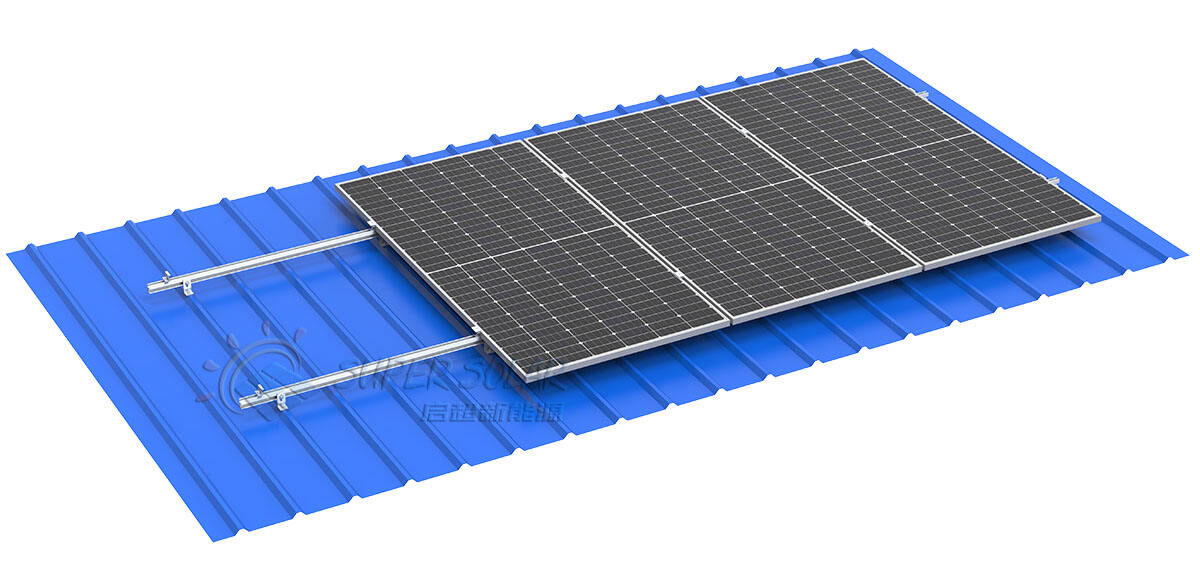

Mounting systems for solar panels serve as the critical foundation that secures photovoltaic arrays to various surfaces, ensuring optimal energy generation while maintaining structural integrity. These sophisticated frameworks are engineered to support heavy solar installations across diverse environments, from residential rooftops to expansive commercial facilities and ground-based utility projects. The primary function of mounting systems for solar panels extends beyond simple attachment, encompassing precise angle optimization, weather resistance, and long-term durability that matches the 25-30 year lifespan of modern solar installations. Modern mounting systems for solar panels incorporate advanced materials such as anodized aluminum and stainless steel components, delivering exceptional corrosion resistance and mechanical strength. These systems feature modular designs that accommodate various panel configurations while maintaining flexibility for future expansions or modifications. The technological sophistication includes integrated grounding pathways, streamlined cable management solutions, and tool-free assembly mechanisms that significantly reduce installation complexity and labor costs. Contemporary mounting systems for solar panels utilize pre-engineered components that have undergone rigorous testing for wind loads, seismic activity, and thermal cycling, ensuring compliance with international building codes and safety standards. The applications span multiple sectors including residential installations on pitched and flat rooftops, commercial buildings requiring ballasted systems, agricultural facilities with dual-use capabilities, and utility-scale ground-mount projects covering hundreds of acres. Additionally, specialized mounting systems for solar panels accommodate unique installations such as carports, floating arrays on water bodies, and tracking systems that follow the sun's trajectory throughout the day. These versatile solutions enable solar deployment across virtually any terrain or structure, maximizing the potential for clean energy generation while adapting to specific site conditions and regulatory requirements.