china solar panel mounting factory

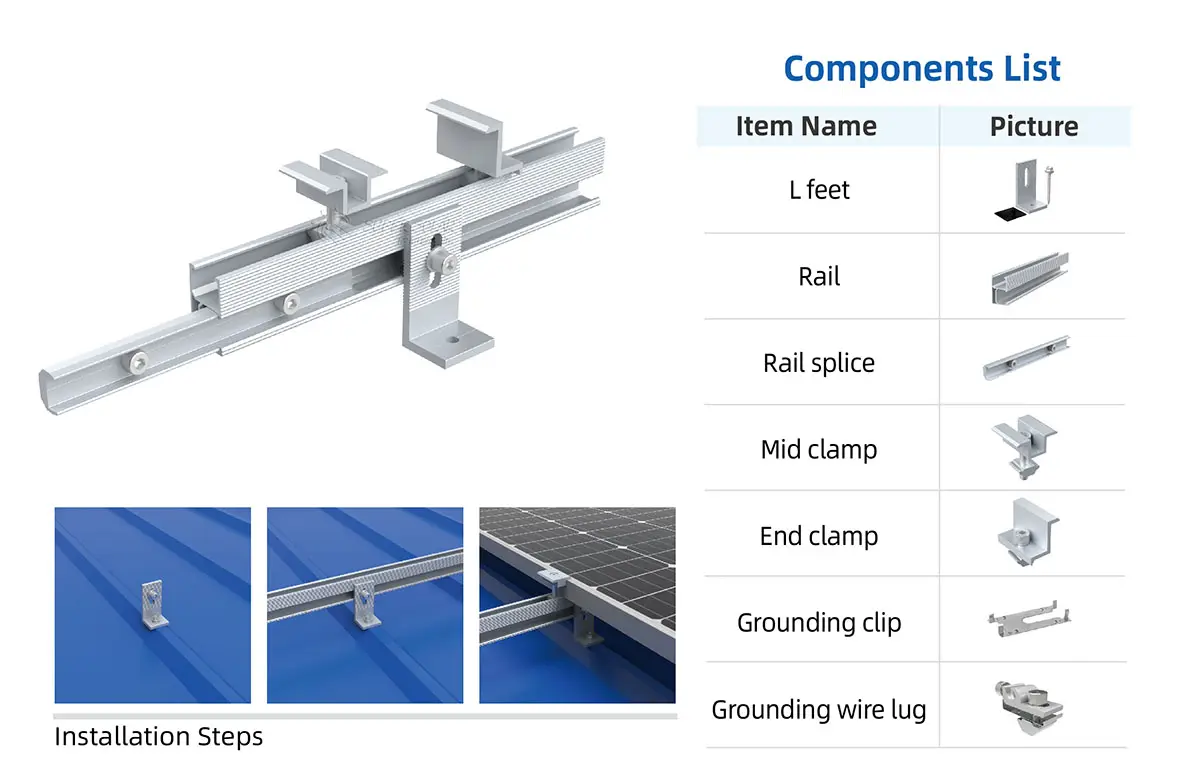

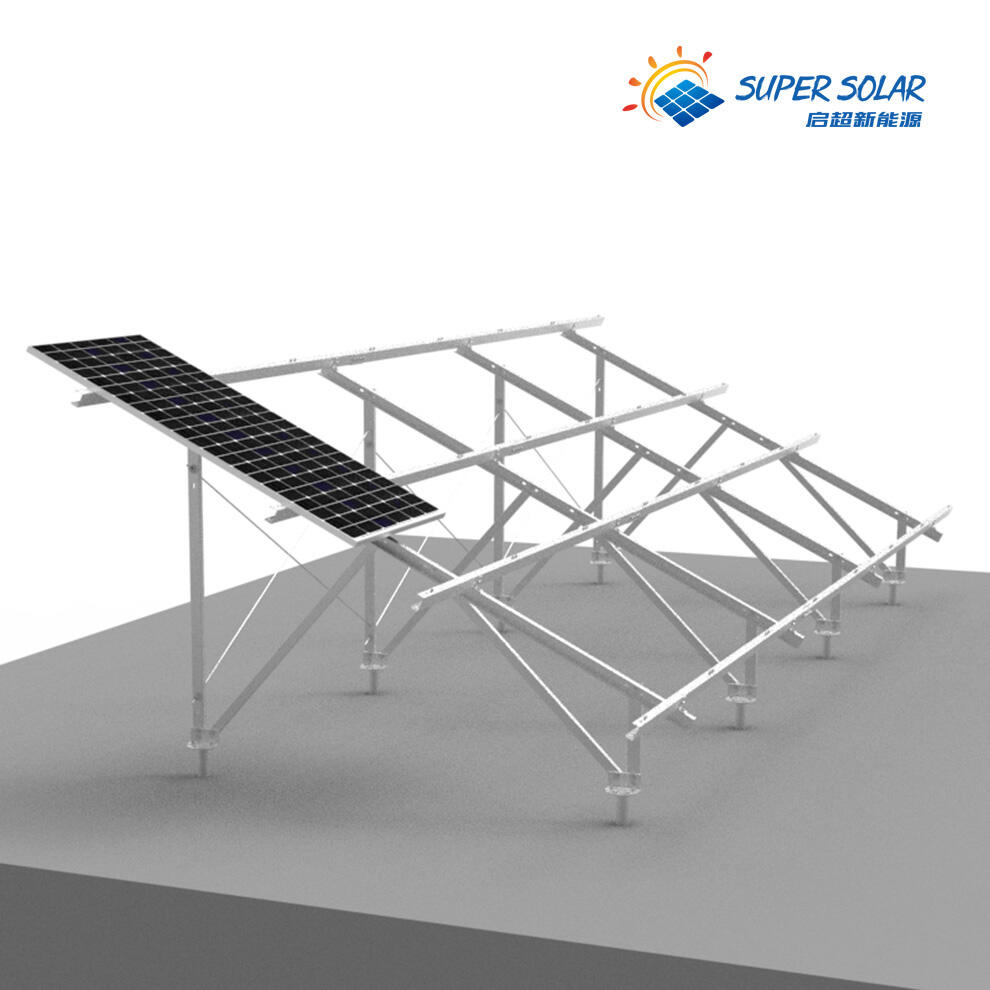

A China solar panel mounting factory serves as a specialized manufacturing facility dedicated to producing high-quality mounting systems and hardware components essential for solar photovoltaic installations worldwide. These factories focus on designing, engineering, and manufacturing comprehensive mounting solutions that secure solar panels to various surfaces including rooftops, ground structures, and commercial buildings. The primary function of a China solar panel mounting factory involves creating durable, weather-resistant mounting rails, clamps, brackets, and fastening systems that ensure optimal panel positioning and long-term structural integrity. Advanced manufacturing processes within these facilities incorporate precision machining, automated welding, and quality control testing to produce components that meet international standards and certifications. The technological features of a China solar panel mounting factory include computer-aided design systems for custom solutions, robotic assembly lines for consistent production quality, and comprehensive testing laboratories that verify load-bearing capacities and corrosion resistance. These factories typically employ galvanized steel, aluminum alloys, and stainless steel materials to create mounting systems capable of withstanding extreme weather conditions, seismic activity, and thermal expansion cycles. Applications for products manufactured in these facilities span residential rooftop installations, utility-scale solar farms, commercial building integrations, and specialized mounting solutions for challenging terrain or unique architectural requirements. Many China solar panel mounting factory operations integrate lean manufacturing principles to optimize production efficiency while maintaining strict quality standards. The factories often provide customization services, allowing for tailored mounting solutions that accommodate specific project requirements, local building codes, and environmental considerations. Export capabilities enable these facilities to serve global markets, supporting renewable energy projects across different continents and climate zones.