safe solar roof mounting in stock

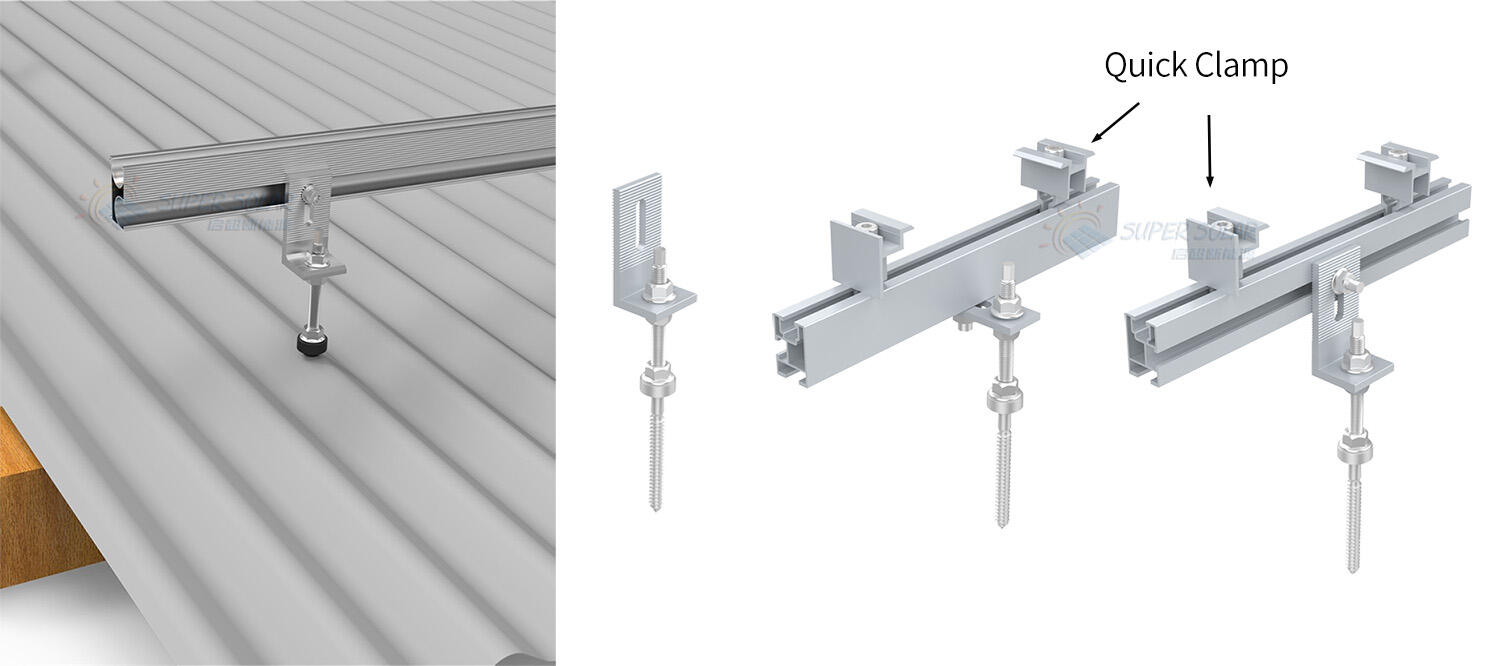

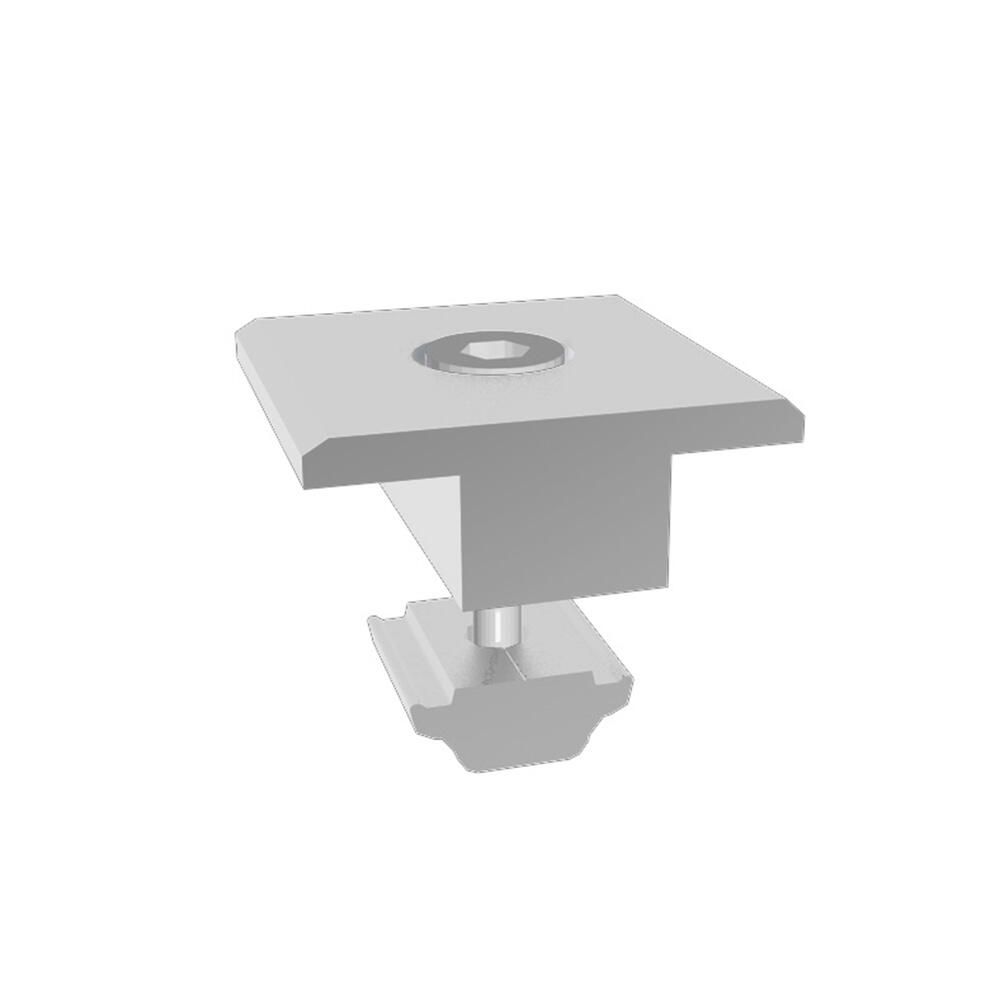

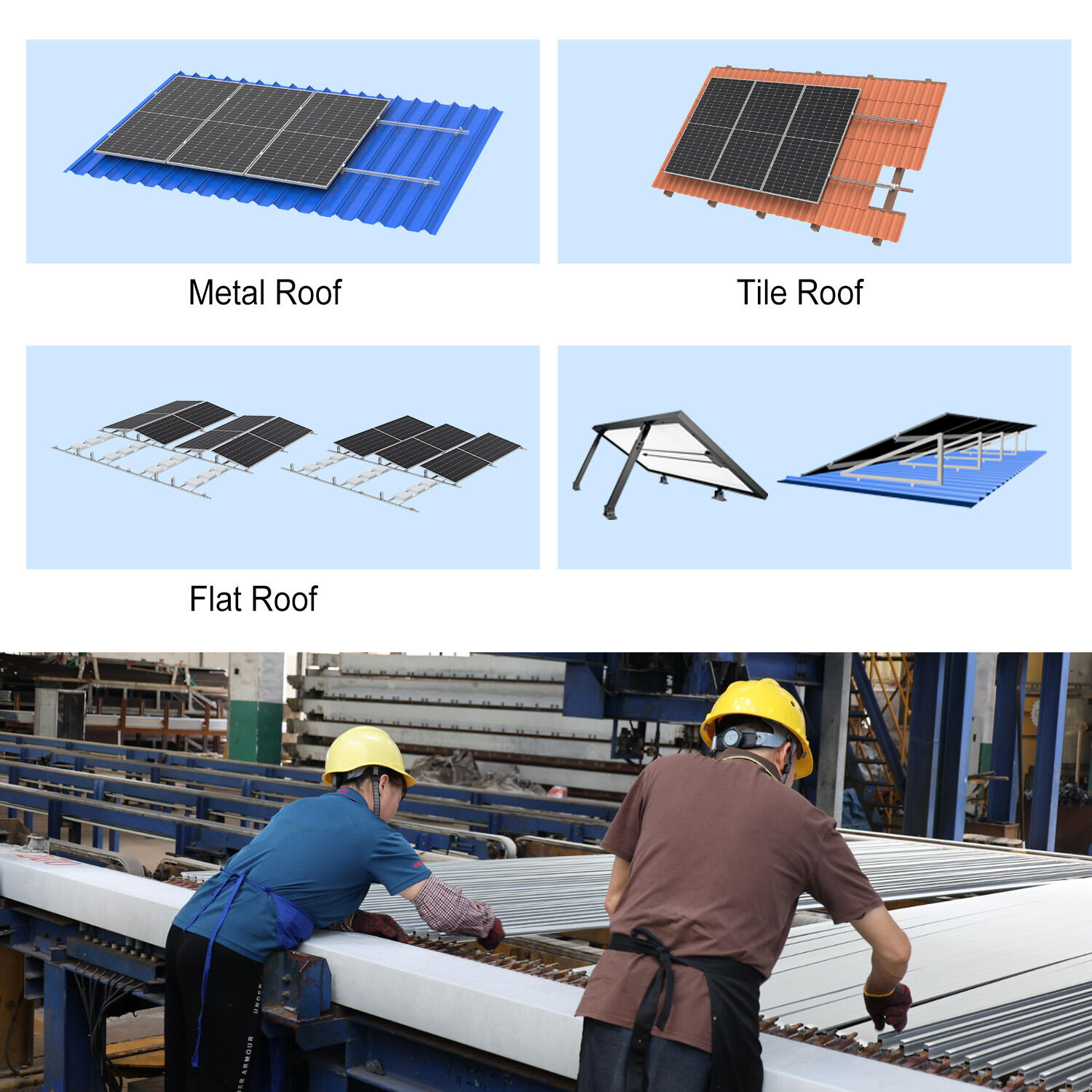

Safe solar roof mounting in stock represents a critical infrastructure component that enables secure installation of photovoltaic systems on residential and commercial rooftops. These mounting systems serve as the foundational support structure that connects solar panels to various roof types while maintaining structural integrity and weather resistance. The primary function of safe solar roof mounting in stock involves creating a stable platform that distributes the weight of solar arrays evenly across roof surfaces, preventing damage to underlying structures while ensuring optimal panel positioning for maximum energy generation. Modern mounting systems incorporate advanced engineering principles that account for wind loads, snow accumulation, thermal expansion, and seismic activity to guarantee long-term performance and safety. Technological features of safe solar roof mounting in stock include corrosion-resistant aluminum alloy construction, adjustable tilt mechanisms for optimal sun exposure, integrated grounding systems for electrical safety, and modular designs that accommodate various panel sizes and configurations. These systems utilize precision-engineered rails, clamps, and fasteners manufactured to exact specifications, ensuring consistent quality and compatibility across different installation scenarios. The mounting hardware incorporates weather-sealed connections, stainless steel components in high-stress areas, and protective coatings that resist ultraviolet degradation and environmental corrosion. Applications for safe solar roof mounting in stock span residential installations on asphalt shingle, tile, metal, and flat membrane roofing systems, as well as commercial projects requiring large-scale array deployment. The versatility of these mounting solutions enables installation on pitched roofs ranging from shallow slopes to steep angles, accommodating diverse architectural styles and regional building codes. Professional installers rely on safe solar roof mounting in stock to complete projects efficiently while meeting strict safety standards and manufacturer warranties that protect both property owners and installation contractors from potential liability issues.