solar mounting system for tin roof suppliers

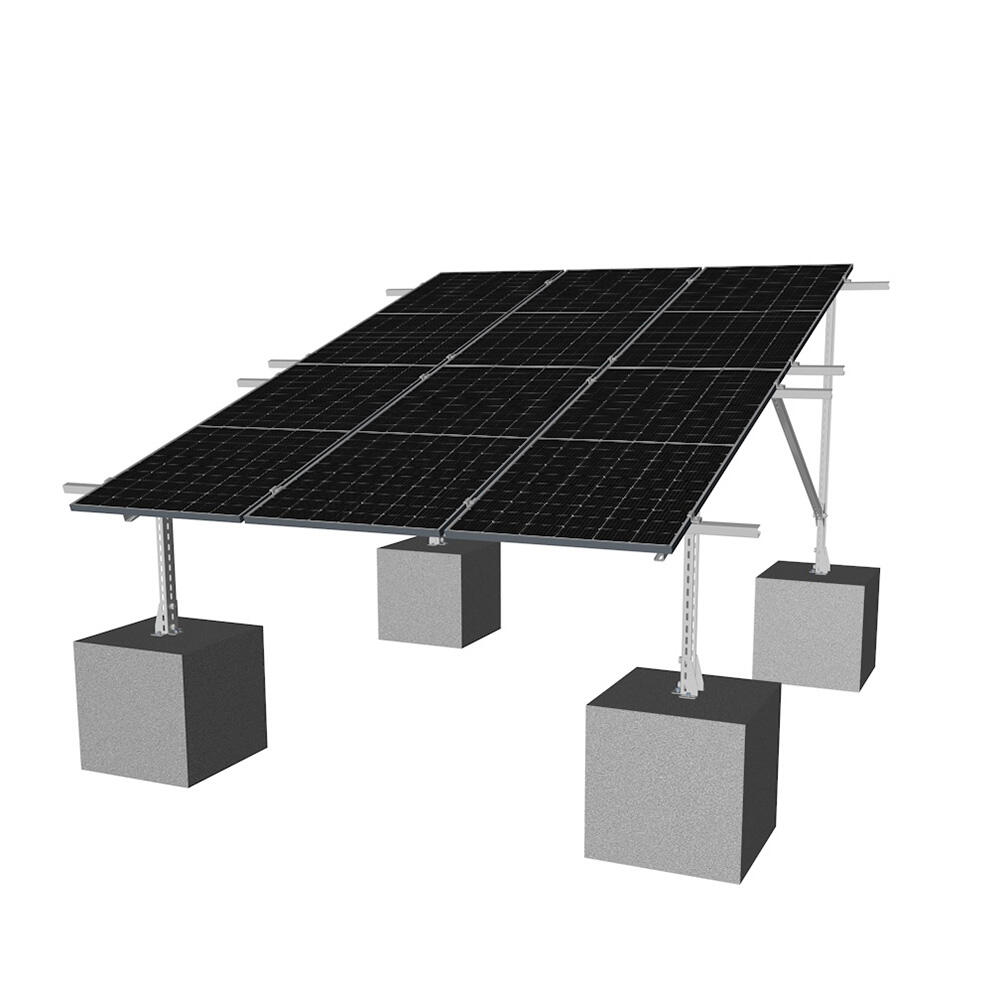

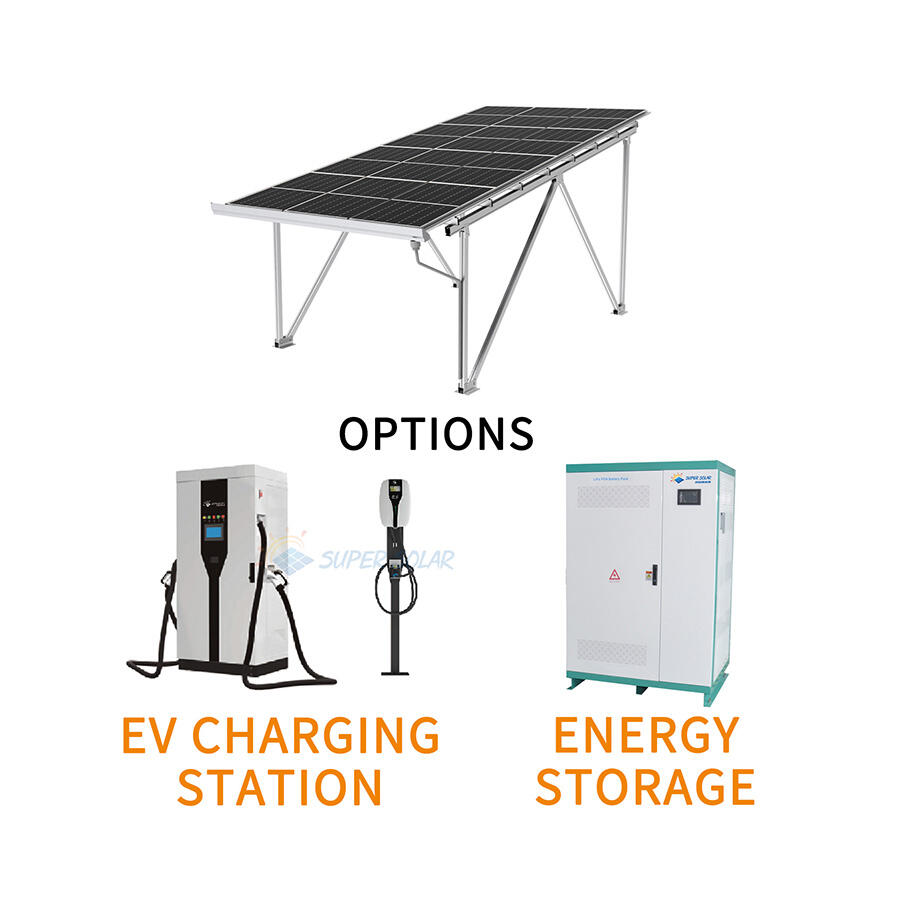

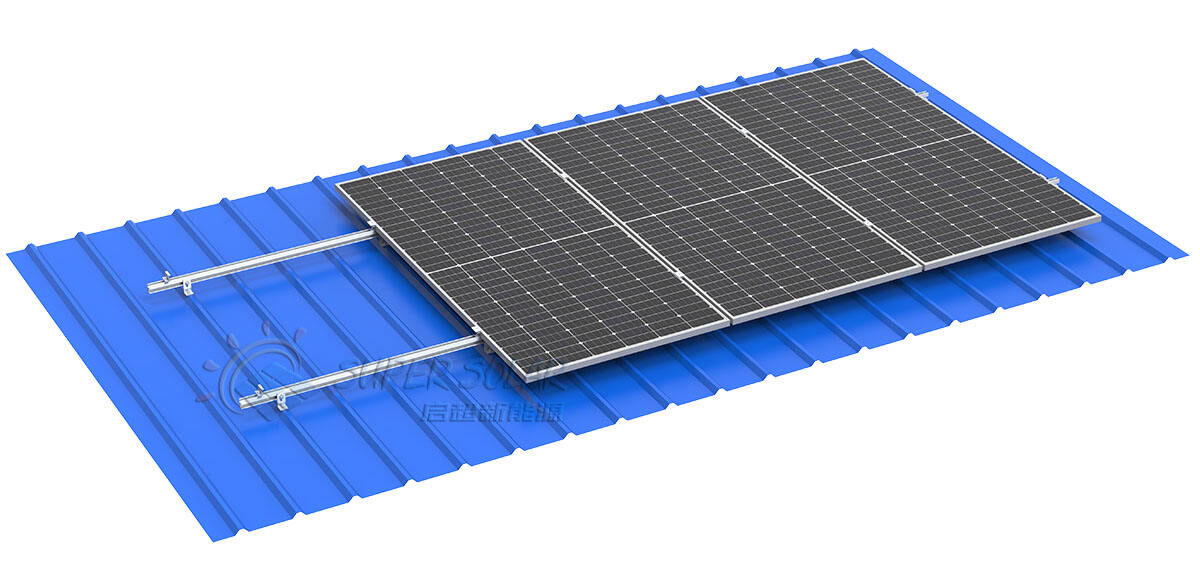

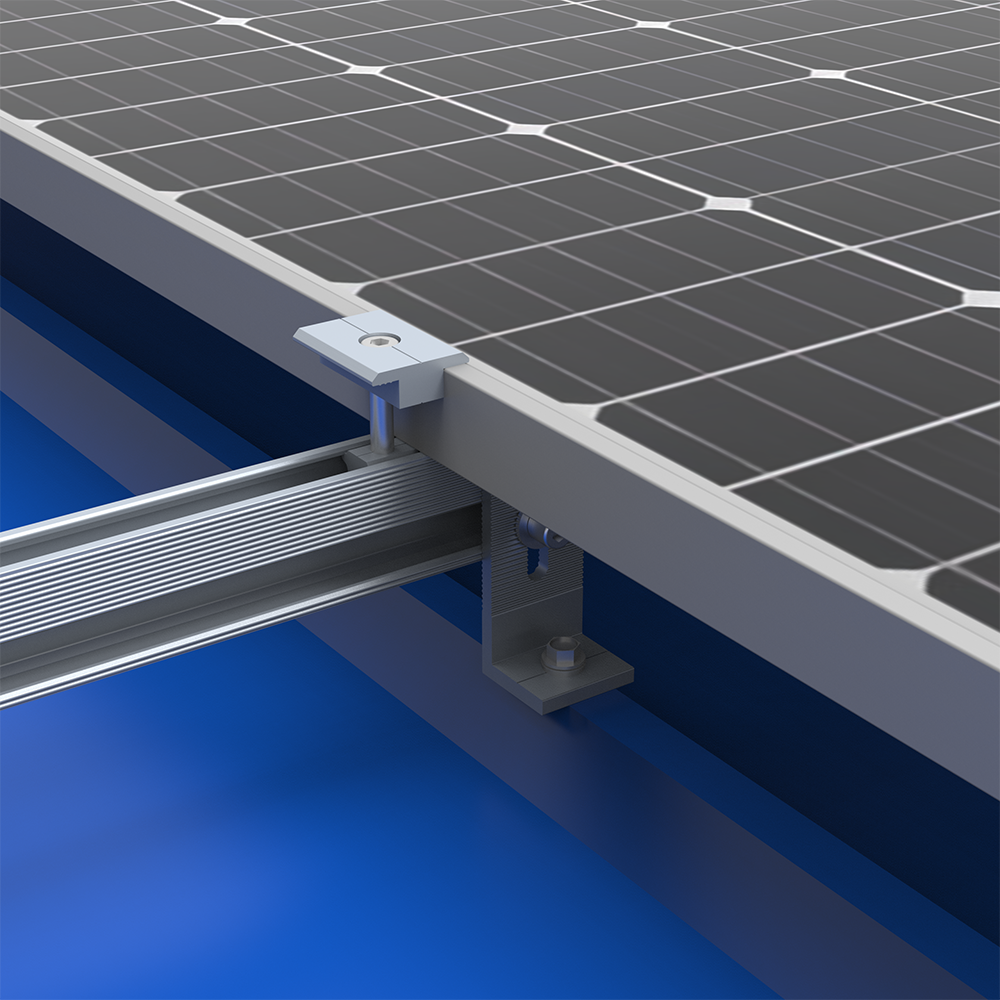

Solar mounting systems for tin roof suppliers represent a specialized engineering solution designed to securely install photovoltaic panels on corrugated metal and tin roofing surfaces. These comprehensive mounting solutions consist of precisely engineered rails, clamps, brackets, and hardware components that work together to create a robust foundation for solar installations. The primary function of these mounting systems centers on providing secure attachment points that distribute the weight of solar panels evenly across the tin roof structure while maintaining the roof's integrity and weatherproofing capabilities. Technological features include corrosion-resistant aluminum and stainless steel construction that withstands harsh environmental conditions, adjustable tilt mechanisms for optimal solar panel positioning, and innovative clamping systems that grip tin roof profiles without penetrating the roofing material. The mounting systems incorporate advanced wind load calculations and structural engineering principles to ensure installations meet local building codes and safety standards. Applications span residential homes, commercial buildings, agricultural structures, and industrial facilities where tin roofing is prevalent. These solar mounting systems for tin roof suppliers enable the transformation of existing metal rooftops into productive energy-generating surfaces without compromising structural integrity. The modular design allows for flexible panel configurations, accommodating various roof sizes and shapes while maintaining consistent performance standards. Professional installers benefit from streamlined installation processes that reduce labor time and minimize potential installation errors. The systems feature pre-assembled components and clear installation guidelines that simplify the mounting process for qualified technicians. Quality solar mounting systems for tin roof suppliers undergo rigorous testing protocols to verify their durability under extreme weather conditions including high winds, snow loads, and temperature fluctuations, ensuring long-term reliability for solar investments.