solar panel mounting track

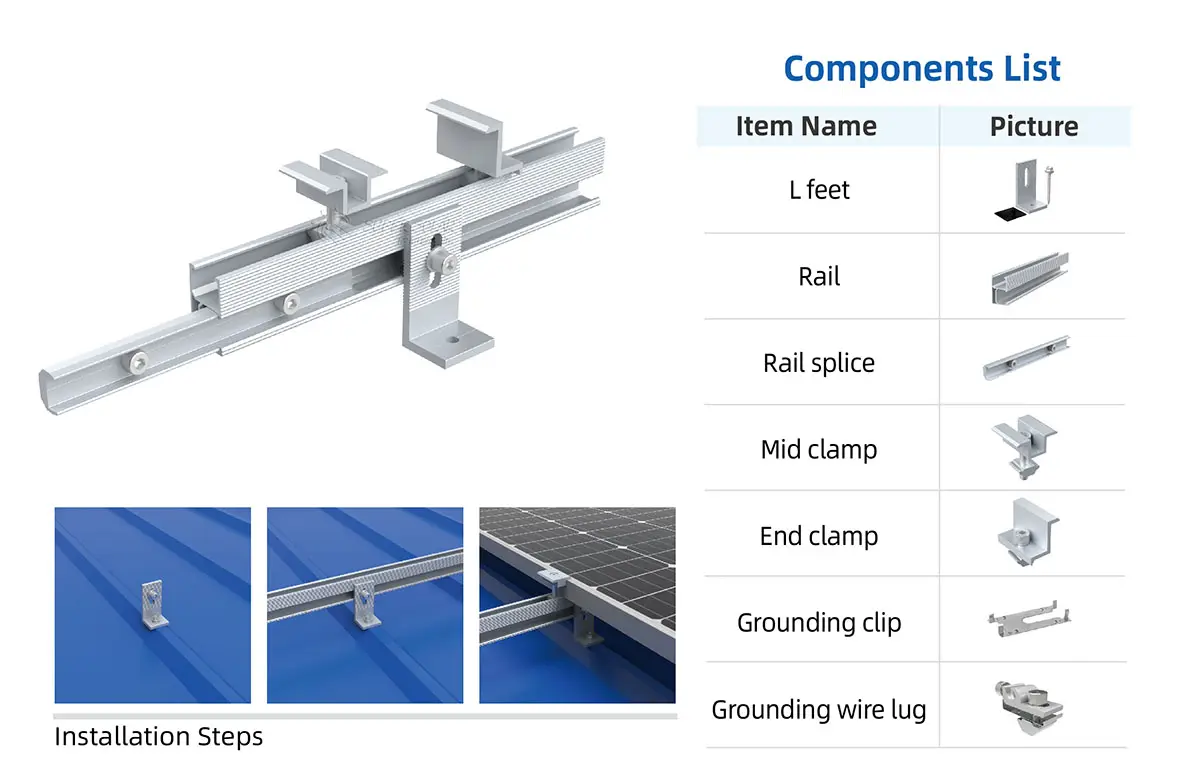

The solar panel mounting track represents a fundamental component in modern photovoltaic installation systems, serving as the backbone for securing solar panels to various surfaces and structures. This innovative hardware solution provides a reliable foundation that ensures optimal panel positioning while maintaining structural integrity throughout the system's operational lifetime. Solar panel mounting track systems consist of precisely engineered aluminum rails that create a secure framework for panel attachment, offering versatility across residential, commercial, and industrial applications. The mounting track's design incorporates advanced materials science, utilizing high-grade aluminum alloys that resist corrosion and weathering while maintaining exceptional strength-to-weight ratios. These tracks feature standardized dimensions that accommodate various panel sizes and configurations, enabling installers to create customized arrays that maximize energy production potential. The technology behind solar panel mounting track systems includes integrated grounding capabilities, built-in drainage channels, and compatibility with multiple attachment methods including clamps, bolts, and specialized fasteners. Installation flexibility remains a key characteristic, as these tracks adapt to different roof types, ground-mount configurations, and tracking systems that follow the sun's movement throughout the day. The mounting track's engineering ensures proper air circulation beneath panels, preventing overheating and maintaining optimal performance levels. Quality manufacturing processes guarantee dimensional accuracy and surface treatments that extend service life beyond 25 years, matching the longevity expectations of modern solar installations. The solar panel mounting track's modular design facilitates system expansion, allowing property owners to add panels incrementally as energy needs grow or budgets permit. This adaptability makes the mounting track an essential investment for sustainable energy infrastructure development.