super solar mini rail mounting system for trapezoidal sheet metal

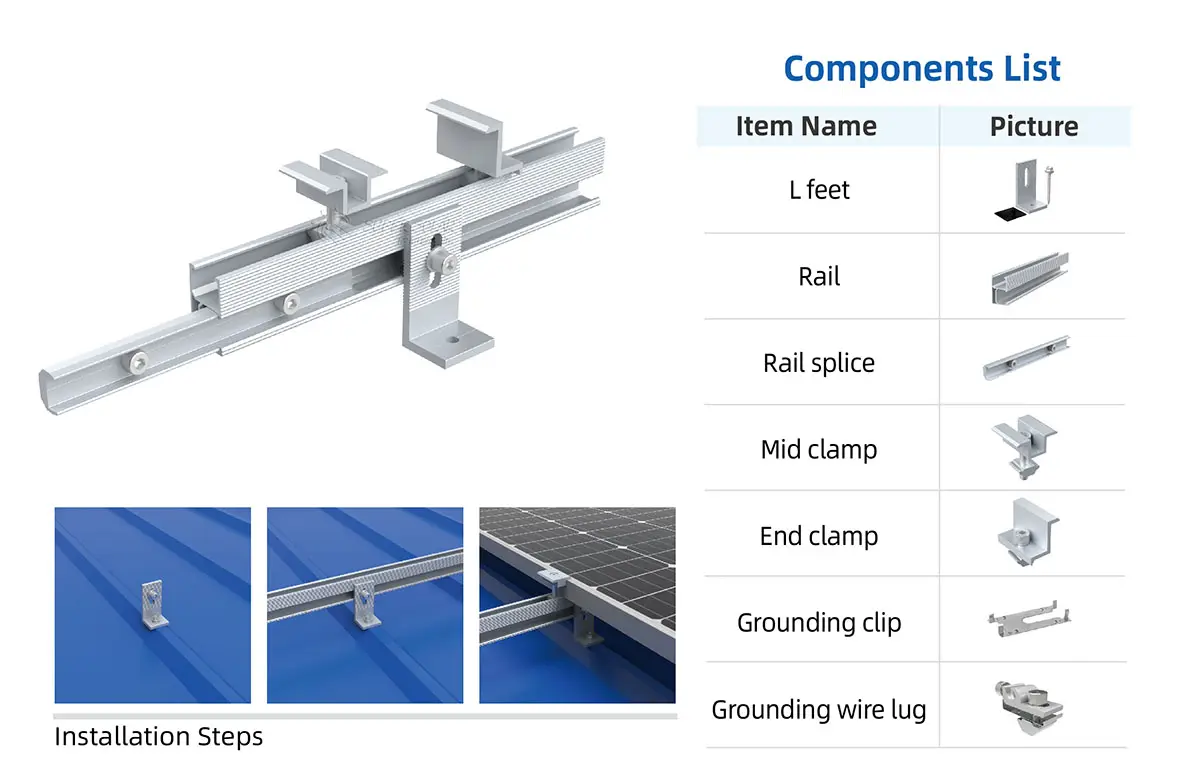

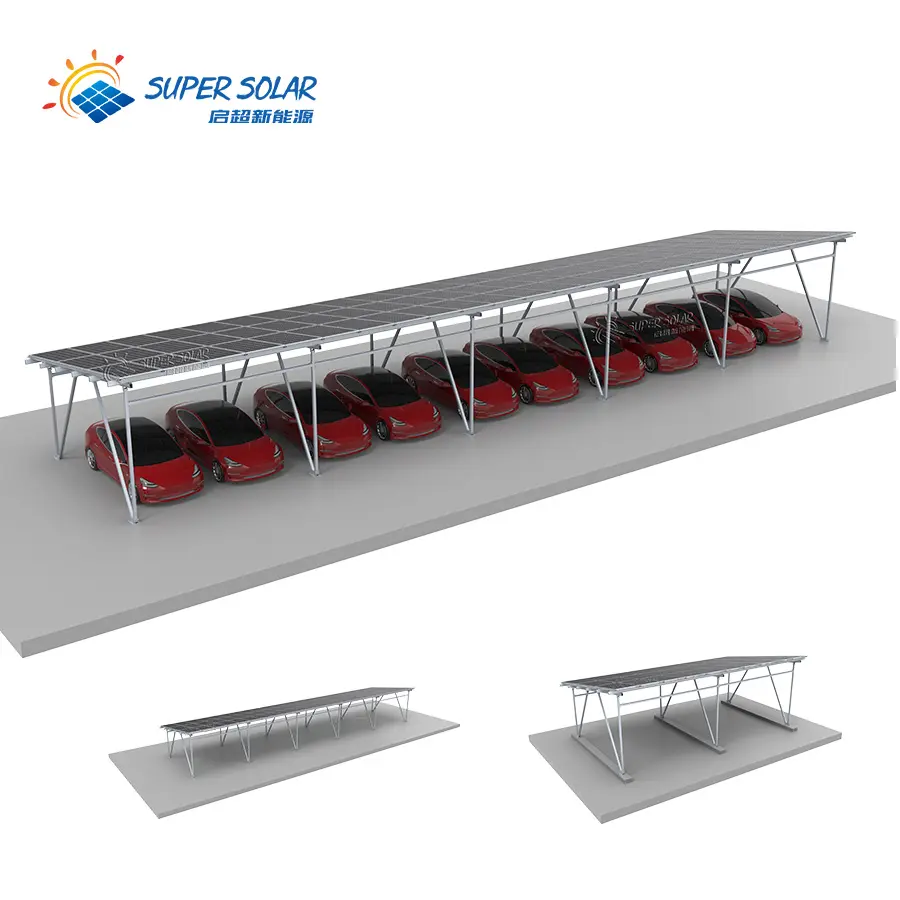

The super solar mini rail mounting system for trapezoidal sheet metal represents a revolutionary advancement in solar panel installation technology, specifically engineered to address the unique challenges posed by corrugated roofing surfaces. This innovative mounting solution combines precision engineering with practical functionality to deliver seamless integration between solar panels and trapezoidal metal roofing systems. The primary function of this mounting system centers on providing secure, weather-resistant attachment points that accommodate the distinctive wave patterns of trapezoidal sheet metal while maintaining optimal panel positioning for maximum energy generation. The system incorporates specialized rail components that conform to the contours of corrugated surfaces, ensuring even weight distribution and preventing stress concentration points that could compromise structural integrity. Technological features include corrosion-resistant aluminum construction with marine-grade anodizing, adjustable height mechanisms for varied roof profiles, and integrated drainage channels that prevent water accumulation. The mounting rails feature pre-engineered connection points that eliminate the need for custom fabrication while maintaining compatibility with standard solar panel configurations. Advanced sealing technology ensures weatherproof performance even under extreme environmental conditions. The system's modular design allows for scalable installations ranging from residential applications to large commercial projects. Installation methodology emphasizes simplicity without sacrificing performance, utilizing proprietary fastening systems that penetrate sheet metal precisely while maintaining waterproof seals. The super solar mini rail mounting system for trapezoidal sheet metal finds extensive application across industrial facilities, agricultural buildings, commercial warehouses, and residential structures featuring corrugated metal roofing. Its versatility extends to both new construction projects and retrofit installations, making it an ideal choice for property owners seeking to maximize renewable energy potential while preserving existing roofing investments. The system's compatibility with various panel technologies ensures long-term adaptability as solar technology continues evolving.