ground mount solar racking manufacturers

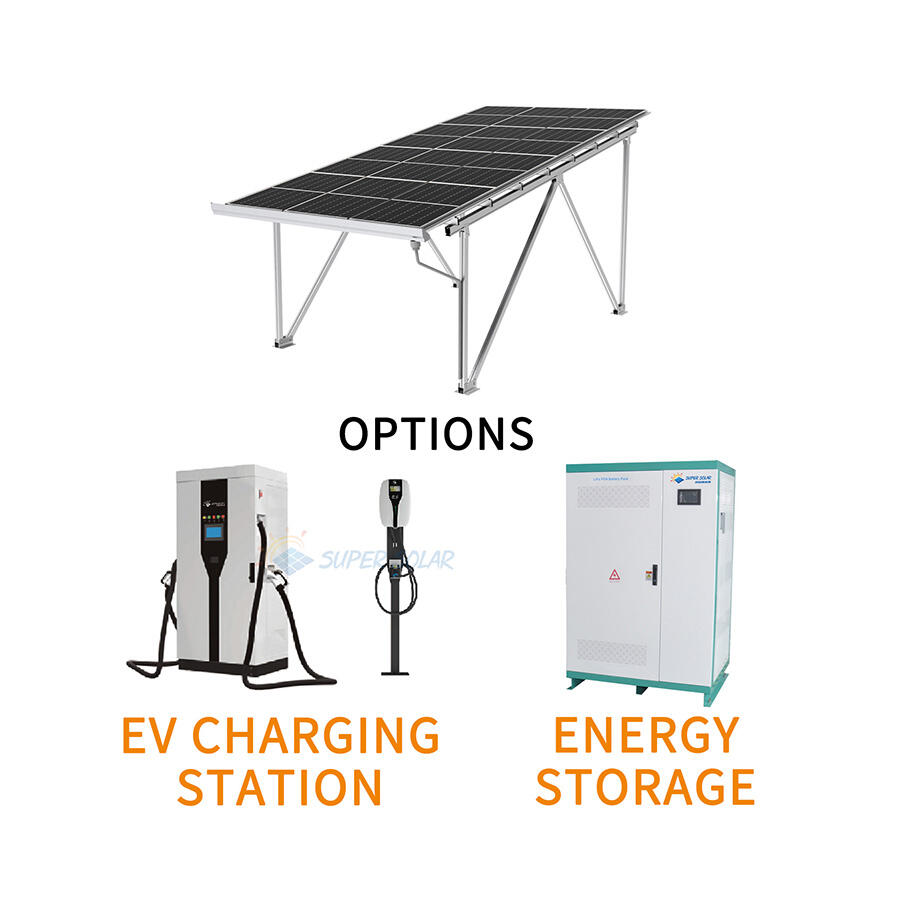

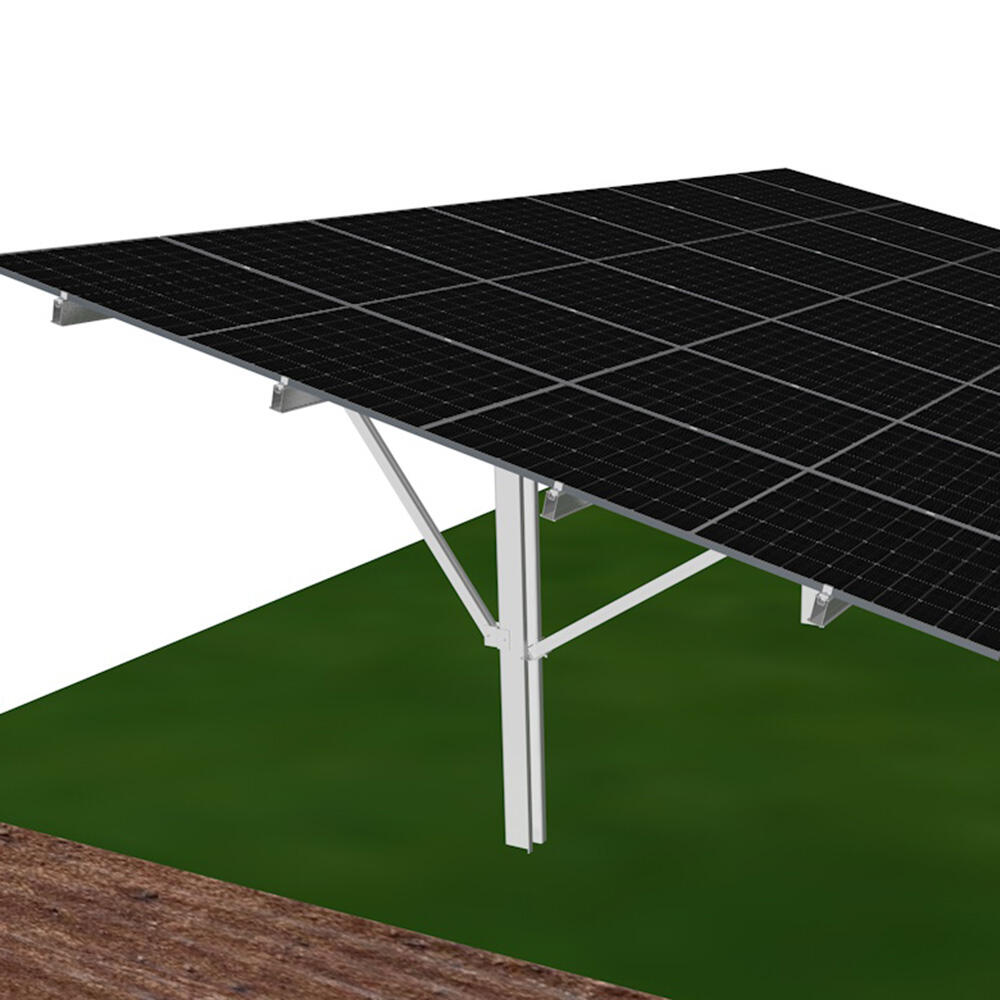

Ground mount solar racking manufacturers represent a vital segment of the renewable energy industry, specializing in the design and production of mounting systems that secure solar panels to the earth's surface. These specialized companies develop robust structural frameworks that elevate photovoltaic modules above ground level, ensuring optimal positioning for maximum solar energy capture. The primary function of ground mount solar racking manufacturers involves engineering mounting solutions that withstand environmental challenges while maintaining panel stability and accessibility for maintenance operations. These systems typically consist of galvanized steel or aluminum frameworks, concrete foundations, and adjustable components that accommodate various terrain conditions and panel configurations. Leading ground mount solar racking manufacturers integrate advanced technologies such as single-axis and dual-axis tracking systems, which automatically adjust panel orientation throughout the day to follow the sun's path. This technological innovation significantly increases energy production compared to fixed-tilt installations. Modern manufacturers also incorporate smart monitoring capabilities, allowing remote assessment of structural integrity and performance metrics. The applications for ground mount solar racking manufacturers extend across residential, commercial, and utility-scale projects. Residential customers benefit from ground-mounted systems when rooftop installations are impractical due to shading, structural limitations, or aesthetic preferences. Commercial enterprises utilize these solutions for large-scale energy generation on available land parcels, while utility companies deploy massive ground-mount arrays for grid-scale power production. Agricultural applications, known as agrivoltaics, represent an emerging market where ground mount solar racking manufacturers create elevated systems that allow farming activities beneath solar panels. The manufacturing process involves precision engineering, quality material selection, and rigorous testing protocols to ensure long-term durability. These companies must comply with local building codes, wind load requirements, and seismic considerations while maintaining cost-effectiveness for widespread adoption.