solar ground mount racking systems

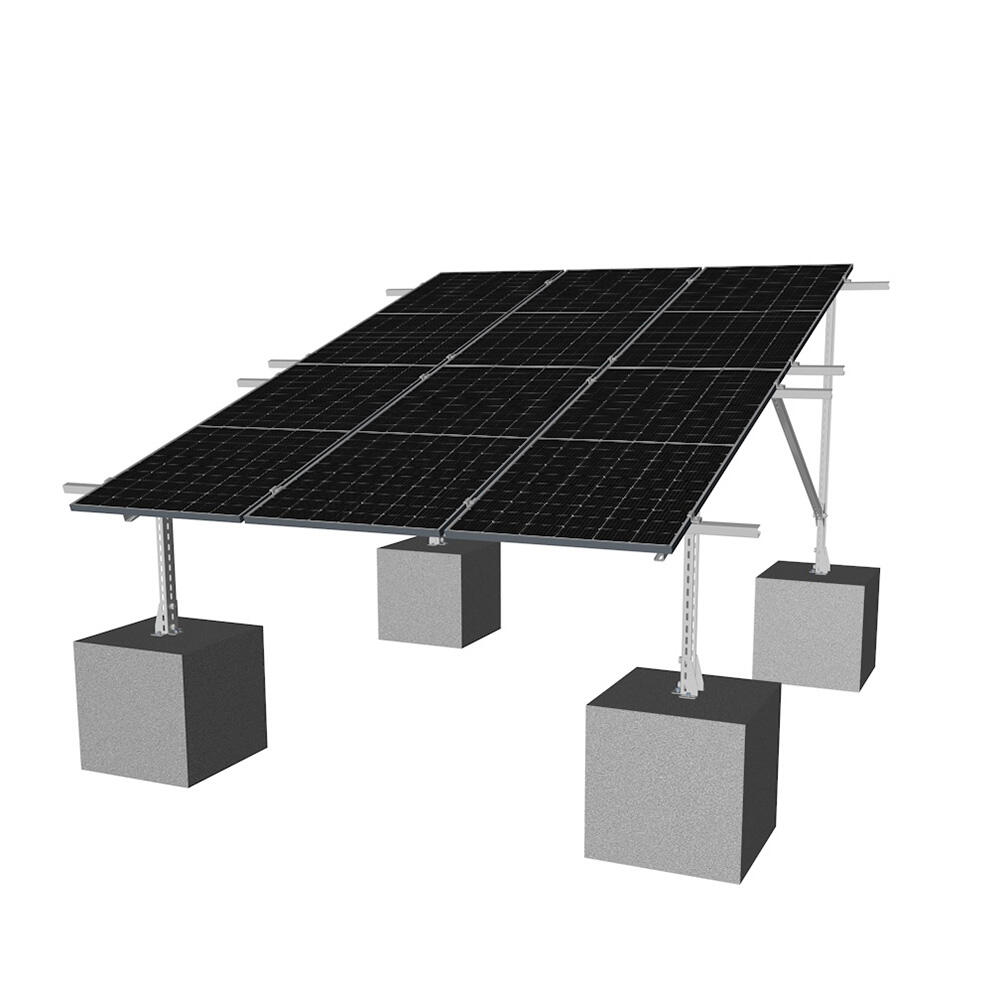

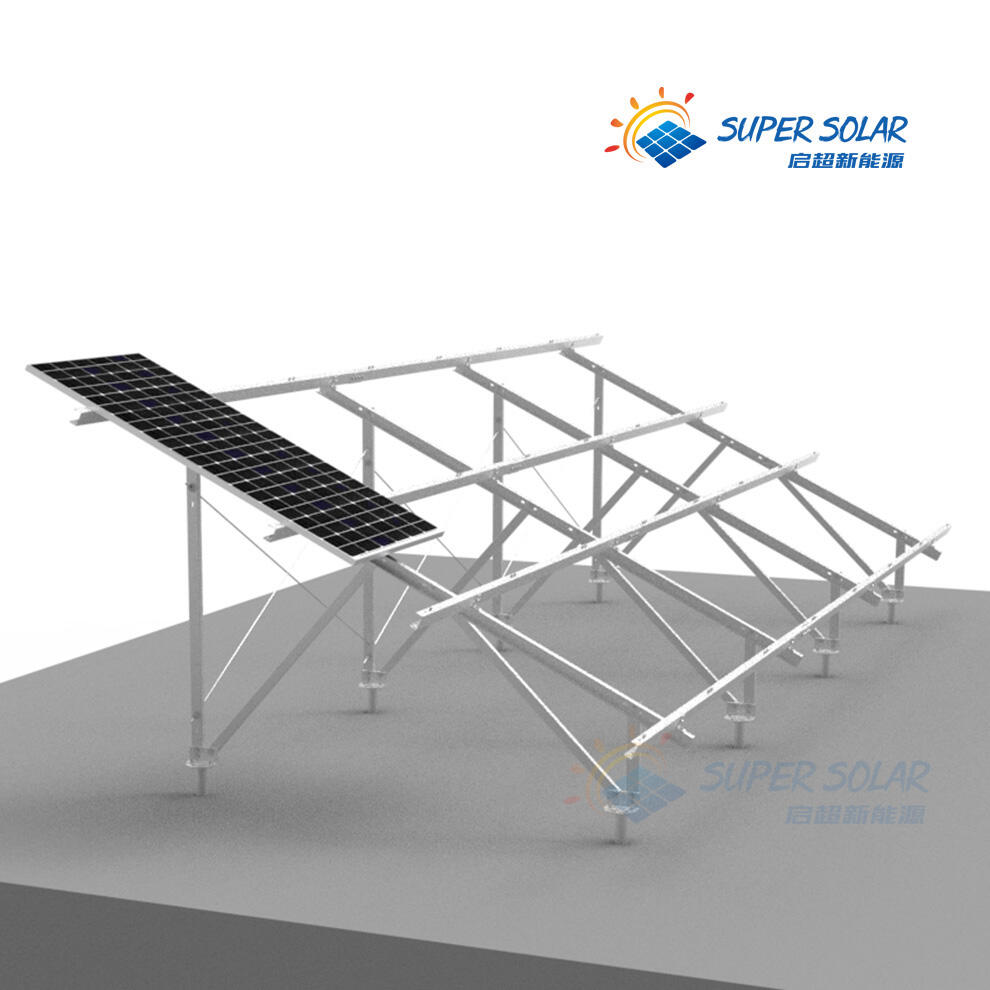

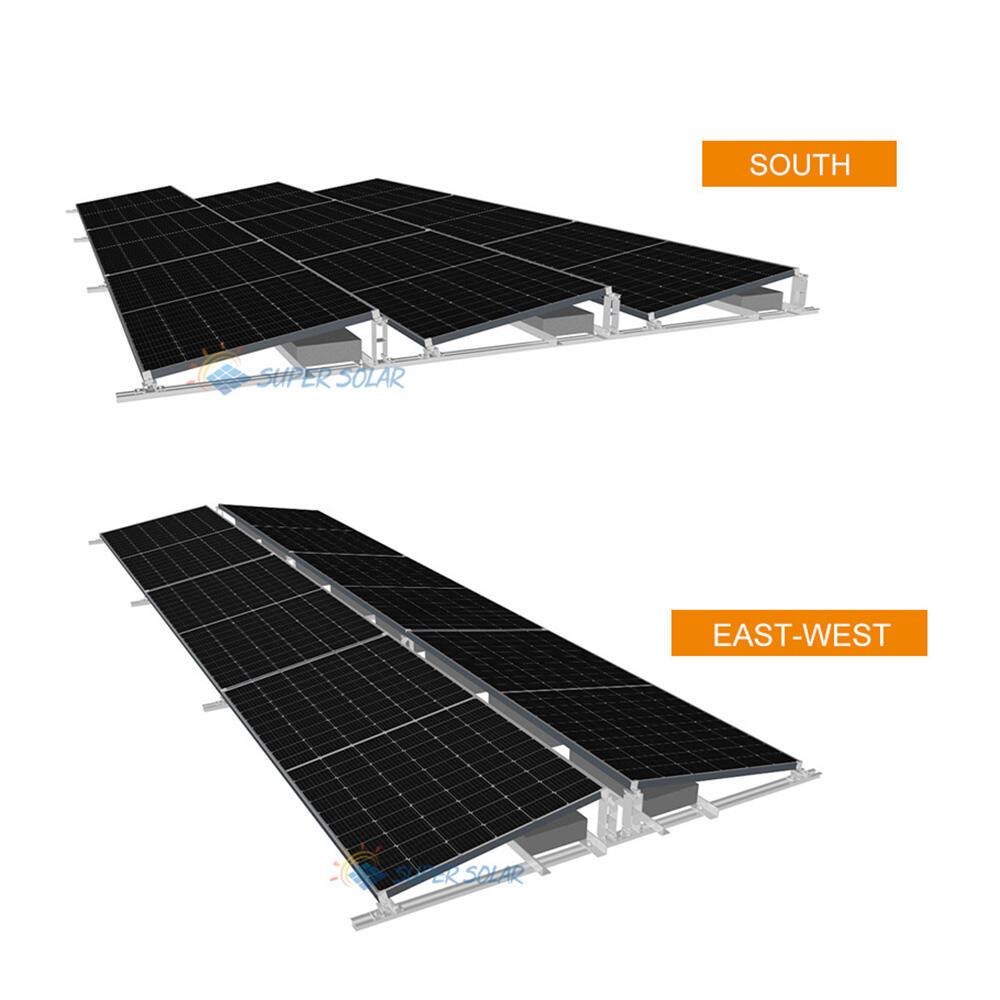

Solar ground mount racking systems represent a fundamental infrastructure solution for utility-scale and commercial solar installations, providing the structural foundation that secures photovoltaic panels to the earth's surface. These sophisticated mounting solutions are engineered to withstand environmental challenges while optimizing energy production through precise panel positioning and orientation. The primary function of solar ground mount racking systems involves creating a stable, durable platform that elevates solar panels at optimal angles for maximum sunlight exposure throughout varying seasons. Modern solar ground mount racking systems incorporate advanced materials such as galvanized steel and aluminum alloys, ensuring exceptional resistance to corrosion and weathering over extended operational periods. The technological features of these systems include adjustable tilt mechanisms that allow for seasonal angle modifications, enhancing energy capture efficiency by up to fifteen percent compared to fixed installations. Pre-engineered foundation solutions within solar ground mount racking systems accommodate diverse soil conditions, from rocky terrain to sandy substrates, utilizing driven piles, concrete ballasts, or helical foundations depending on geological assessments. These mounting solutions integrate seamlessly with various panel types and configurations, supporting both crystalline silicon and thin-film technologies across different wattage specifications. The modular design philosophy behind solar ground mount racking systems enables scalable deployment, allowing projects to expand incrementally while maintaining structural integrity and aesthetic consistency. Advanced drainage considerations built into these systems prevent water accumulation around panel arrays, reducing maintenance requirements and extending equipment lifespan. Applications for solar ground mount racking systems span multiple sectors including utility-scale power generation facilities, commercial rooftop alternatives, agricultural solar farms, and residential installations where roof mounting proves impractical due to structural limitations or shading concerns.