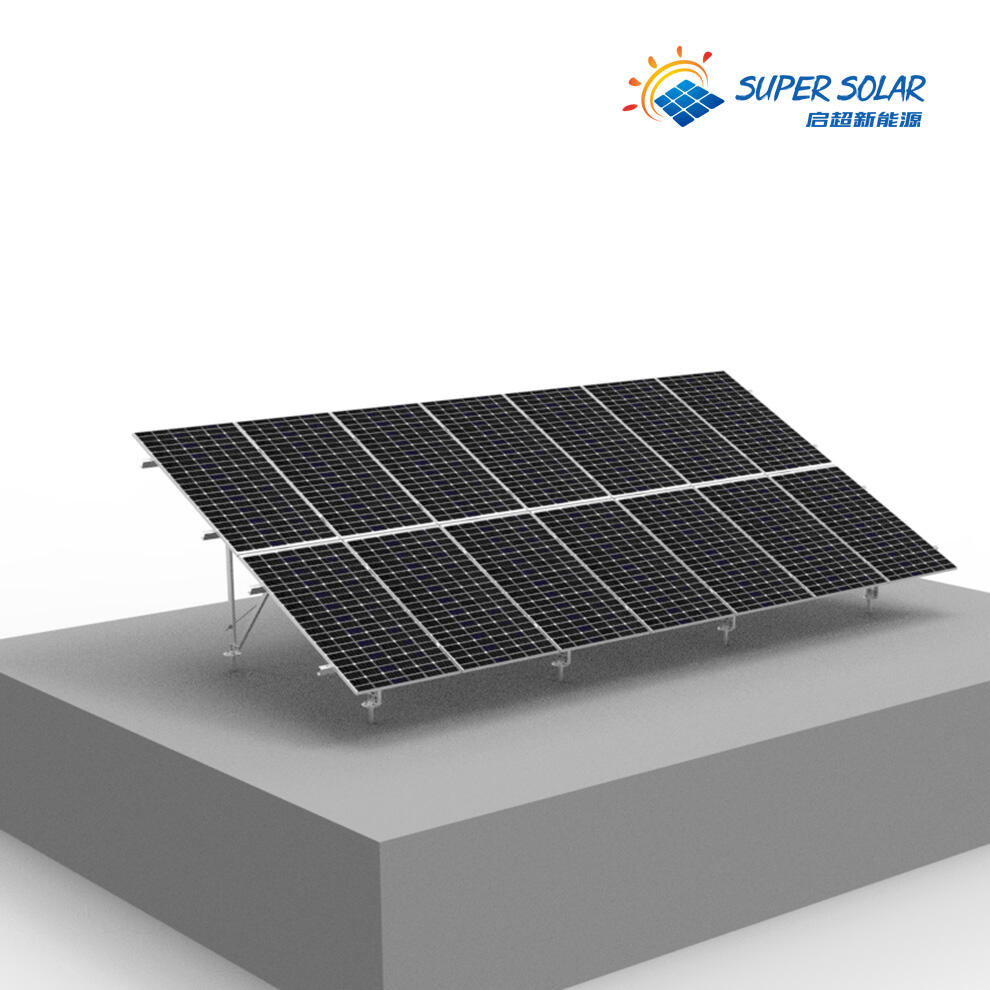

solar ground mounting factory

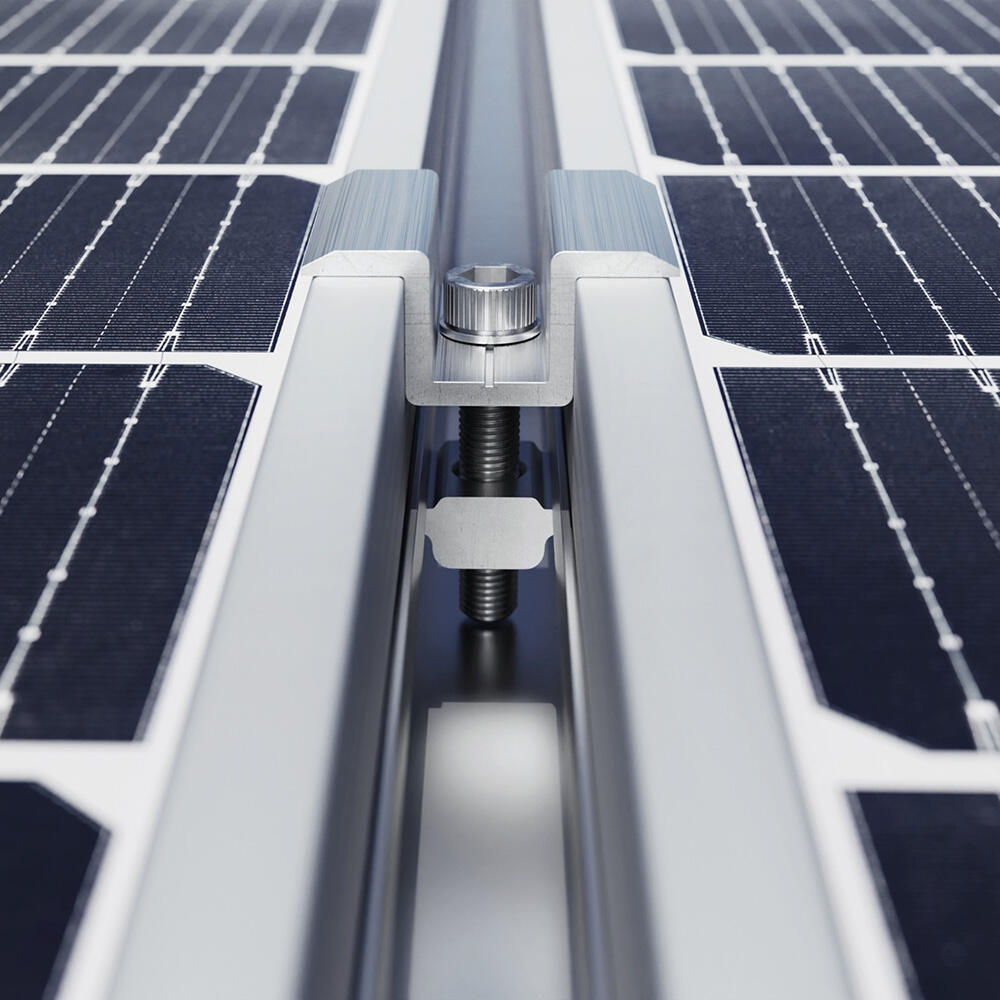

A solar ground mounting factory serves as the cornerstone of renewable energy infrastructure development, specializing in the design, manufacturing, and distribution of ground-mounted solar panel systems. These specialized manufacturing facilities focus on creating robust mounting structures that securely position photovoltaic panels on ground surfaces, maximizing energy capture while ensuring long-term durability. The solar ground mounting factory integrates advanced engineering principles with precision manufacturing techniques to produce components that withstand harsh environmental conditions including wind loads, snow accumulation, and seismic activities. Modern facilities employ state-of-the-art machinery for metal fabrication, welding, galvanizing, and quality control processes. The primary functions encompass research and development of innovative mounting solutions, large-scale production of aluminum and steel components, surface treatment operations, and comprehensive testing protocols. Technological features include computer-aided design systems, automated cutting and forming equipment, powder coating lines, and rigorous quality assurance laboratories. These factories typically maintain ISO certifications and adhere to international standards for structural integrity and material specifications. Applications span across utility-scale solar farms, commercial installations, and residential ground-mount systems. The solar ground mounting factory produces various configurations including fixed-tilt systems, single-axis tracking systems, and dual-axis tracking mechanisms. Each system type offers specific advantages depending on geographical location, solar irradiance patterns, and project requirements. Manufacturing processes incorporate sustainable practices, recycling metal waste, and optimizing energy consumption. The factory environment requires specialized expertise in metallurgy, structural engineering, and renewable energy technologies. Quality control measures ensure products meet stringent performance standards and regulatory compliance. Distribution networks connect these manufacturing hubs with solar installers, engineering firms, and project developers worldwide. The solar ground mounting factory plays a crucial role in accelerating solar energy adoption by providing reliable, cost-effective mounting solutions that maximize return on investment for solar projects.