aluminum solar ground structure manufacturers

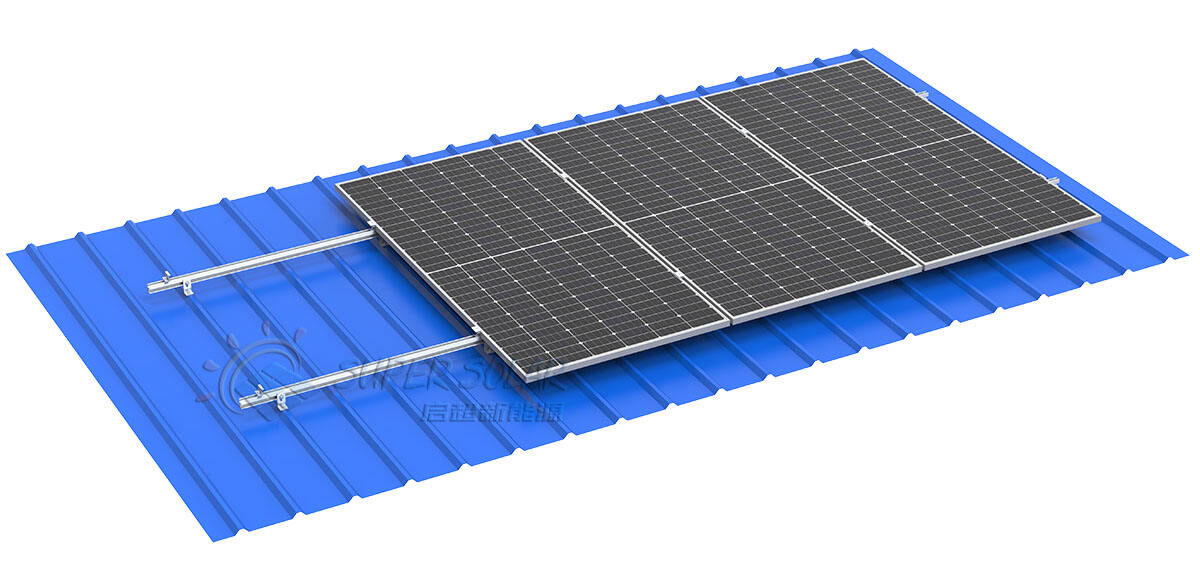

Aluminum solar ground structure manufacturers represent a crucial segment of the renewable energy industry, specializing in the design, production, and supply of mounting systems that secure solar panels to ground-based installations. These manufacturers focus exclusively on aluminum-based solutions, leveraging the metal's exceptional properties to create durable, lightweight, and corrosion-resistant mounting frameworks. The primary function of these structures involves providing stable, secure foundations for photovoltaic panels while optimizing their positioning for maximum solar energy capture. Modern aluminum solar ground structure manufacturers employ advanced engineering techniques to develop modular systems that accommodate various terrain types, weather conditions, and installation requirements. Their products typically feature pre-engineered components that simplify field assembly, reduce installation time, and minimize construction costs. These manufacturers integrate sophisticated design software and finite element analysis to ensure structural integrity under diverse environmental loads including wind, snow, and seismic forces. The technological features of contemporary aluminum solar ground structures include adjustable tilt mechanisms, integrated cable management systems, and compatibility with multiple panel configurations. Many manufacturers now incorporate smart design elements such as optimized spacing for maintenance access, drainage considerations, and thermal expansion accommodation. The applications of these structures span residential installations, commercial solar farms, utility-scale projects, and specialized environments like agricultural solar installations. Leading aluminum solar ground structure manufacturers maintain rigorous quality control standards, often achieving certifications from international testing organizations. They continuously innovate to address evolving industry needs, including compatibility with newer panel technologies, enhanced durability requirements, and cost optimization demands. These manufacturers serve as essential partners in the solar energy ecosystem, enabling efficient deployment of clean energy infrastructure across diverse geographic and climatic conditions while supporting the global transition toward sustainable energy solutions.