durable ground screw solar mounting

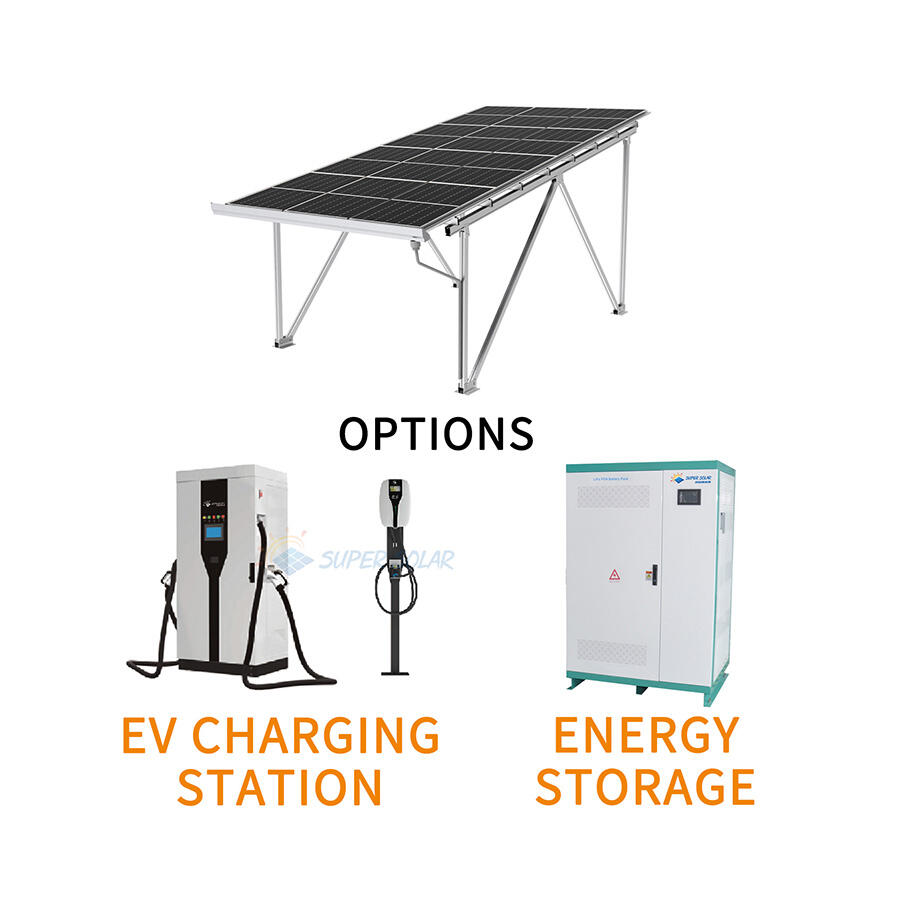

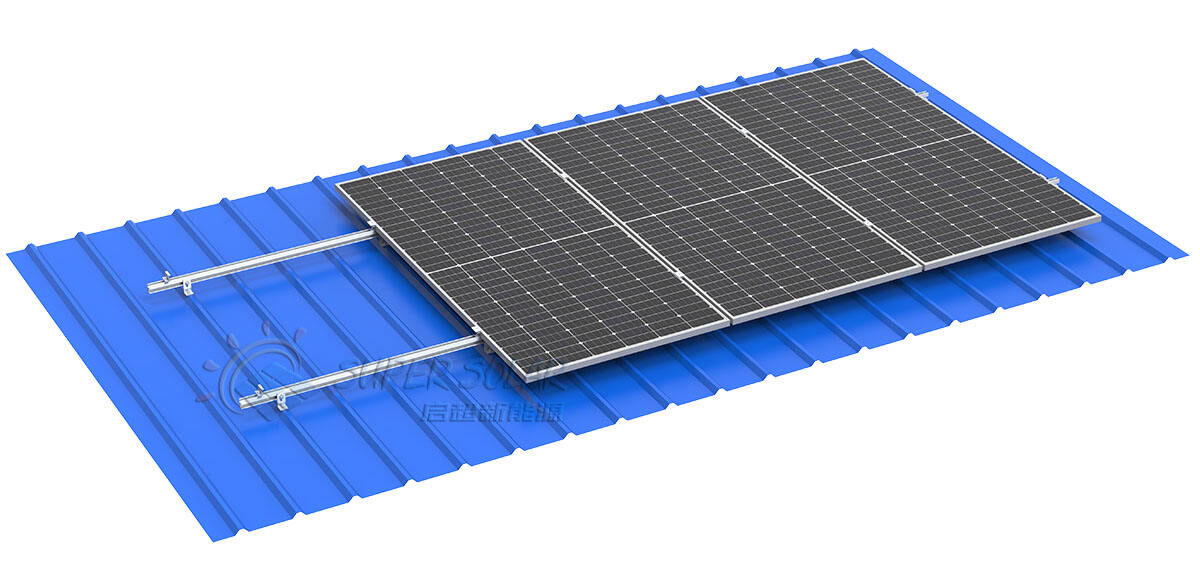

The durable ground screw solar mounting system represents a revolutionary advancement in photovoltaic installation technology, offering superior stability and longevity for solar panel arrays across diverse terrain conditions. This innovative mounting solution utilizes specially engineered ground screws that penetrate deep into various soil types, creating an unshakeable foundation for solar installations without requiring extensive excavation or concrete foundations. The durable ground screw solar mounting system features corrosion-resistant materials, typically galvanized steel or aluminum alloy construction, ensuring decades of reliable performance even in harsh environmental conditions including coastal areas with salt exposure, extreme temperature variations, and high wind zones. The main function of this mounting system centers on providing secure anchoring points for solar panel frameworks while maintaining optimal positioning angles for maximum energy generation. Technological features include pre-engineered screw dimensions calculated for specific soil conditions, integrated leveling mechanisms that accommodate uneven terrain, and modular design components that facilitate rapid installation and future system expansion. The threaded screw design creates exceptional holding power by compacting surrounding soil during installation, effectively increasing load-bearing capacity compared to traditional foundation methods. Applications for durable ground screw solar mounting systems span residential installations, commercial solar farms, utility-scale projects, and specialized environments such as agricultural land where minimal soil disruption is essential. These mounting systems excel in temporary installations, remote locations where concrete delivery is impractical, and projects requiring quick deployment timelines. The versatility of durable ground screw solar mounting makes it particularly valuable for ground-mounted arrays, solar tracking systems, and installations on slopes or irregular terrain where conventional mounting methods prove challenging or cost-prohibitive. Environmental benefits include reduced site preparation requirements, minimal landscape disruption, and complete reversibility for land restoration purposes.