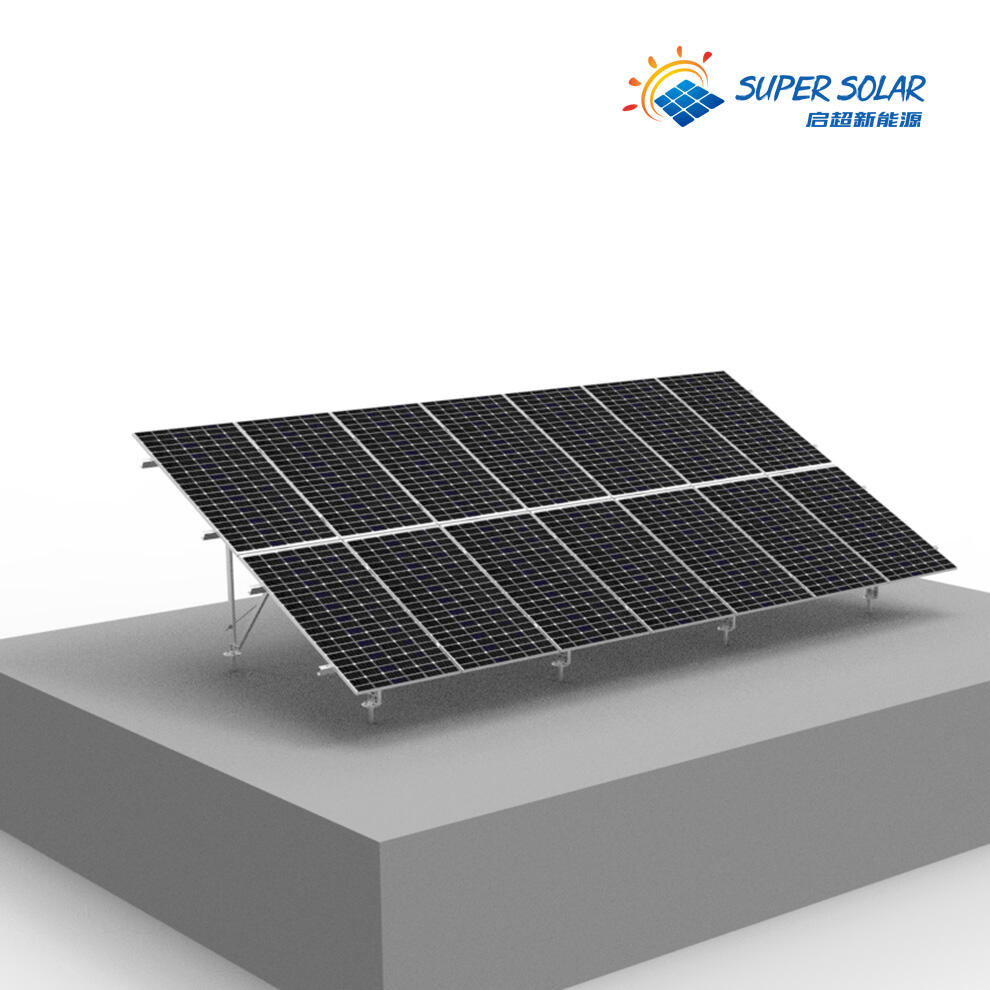

stable ground screw solar mounting

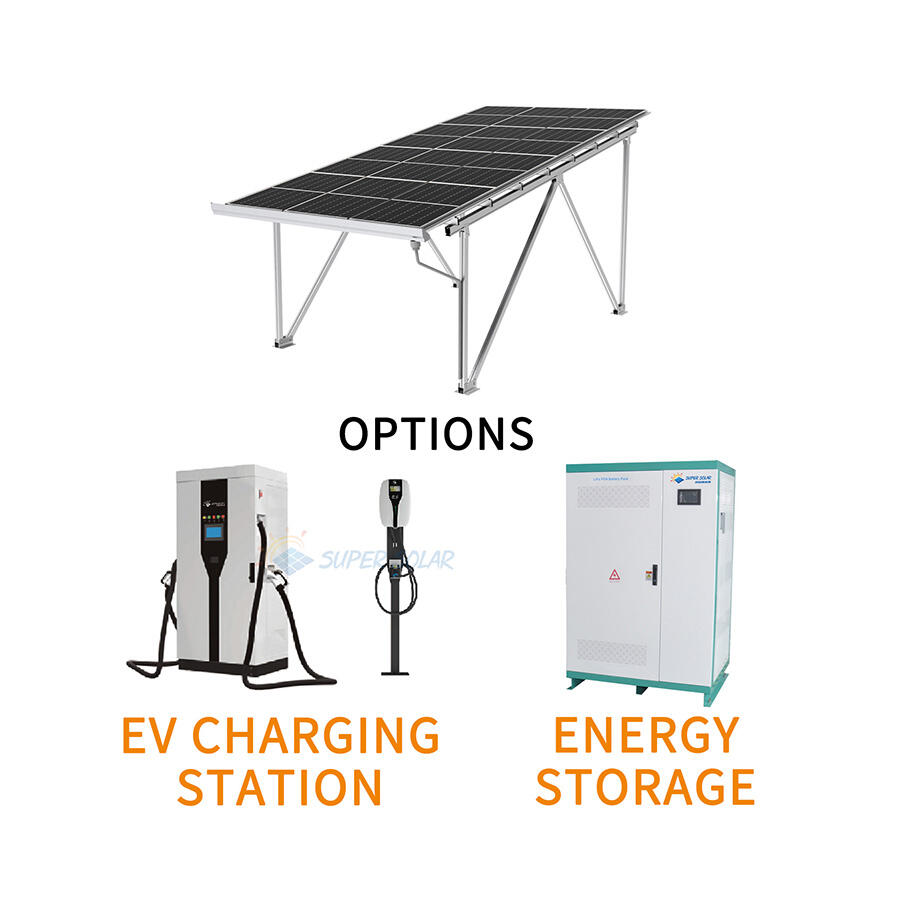

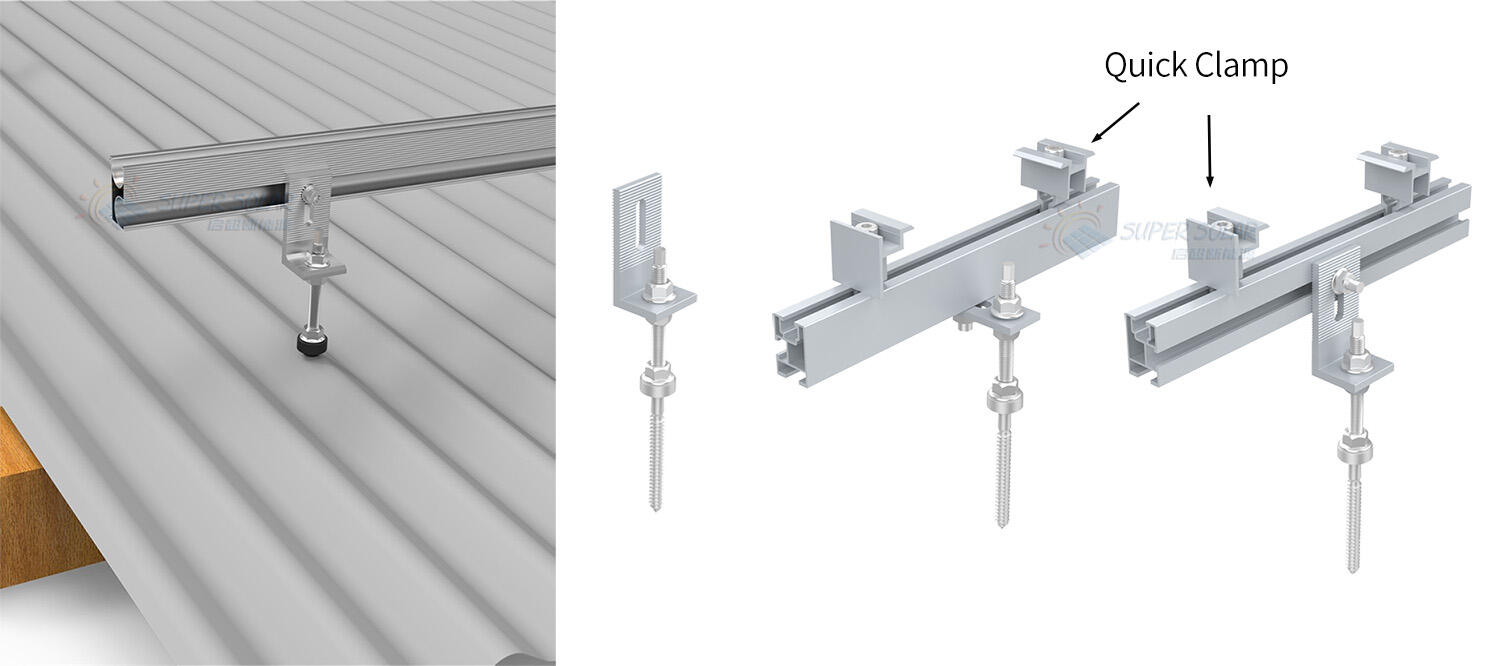

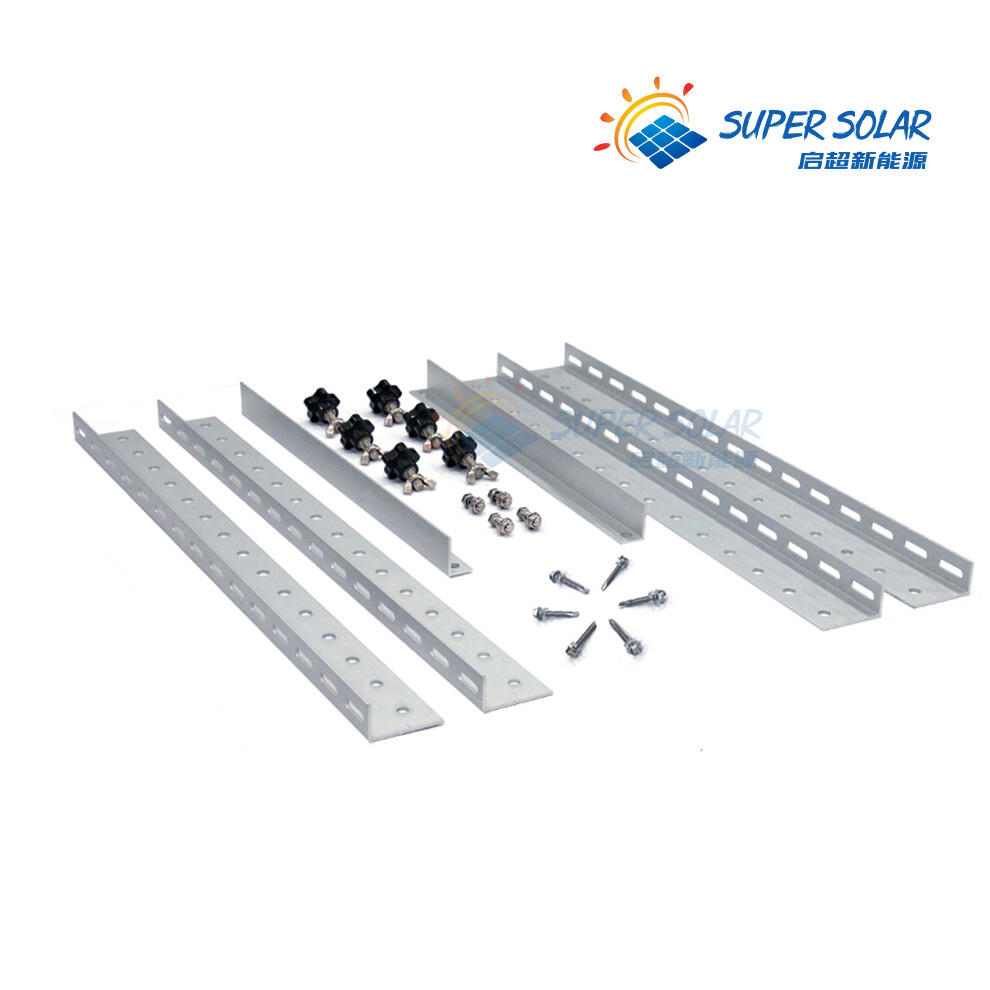

The stable ground screw solar mounting system represents a revolutionary approach to solar panel installation that eliminates the need for traditional concrete foundations. This innovative mounting solution utilizes helical steel screws that are mechanically driven into the ground to create a secure and durable foundation for solar arrays. The stable ground screw solar mounting technology offers exceptional versatility across various soil conditions and terrains, making it an ideal choice for residential, commercial, and utility-scale solar installations. The system consists of galvanized steel screws with specially designed helical blades that cut through soil layers while providing superior holding power. These screws are engineered to withstand extreme weather conditions, including high winds, seismic activity, and freeze-thaw cycles. The mounting brackets and rails are manufactured from corrosion-resistant materials, ensuring long-term structural integrity and optimal solar panel performance. The stable ground screw solar mounting system features adjustable tilt angles that maximize energy production by optimizing solar panel orientation throughout different seasons. Installation teams can easily modify the angle settings to accommodate specific geographic locations and seasonal sun paths. The modular design allows for flexible array configurations, enabling installers to work around obstacles such as trees, buildings, or underground utilities. Quality control measures ensure each stable ground screw solar mounting component meets rigorous engineering standards and load-bearing requirements. The system accommodates various solar panel types and sizes, from standard crystalline silicon panels to advanced thin-film technologies. Environmental considerations are paramount in the design, as the stable ground screw solar mounting system minimizes ground disturbance compared to traditional excavation methods. The reversible installation process means the mounting system can be completely removed without permanent ground alteration, making it perfect for temporary installations or leased land agreements. Advanced engineering calculations determine proper screw depth and spacing based on local soil conditions, wind loads, and seismic requirements, ensuring optimal performance and safety standards.