Versatile Design Adaptability and Future-Proof Technology

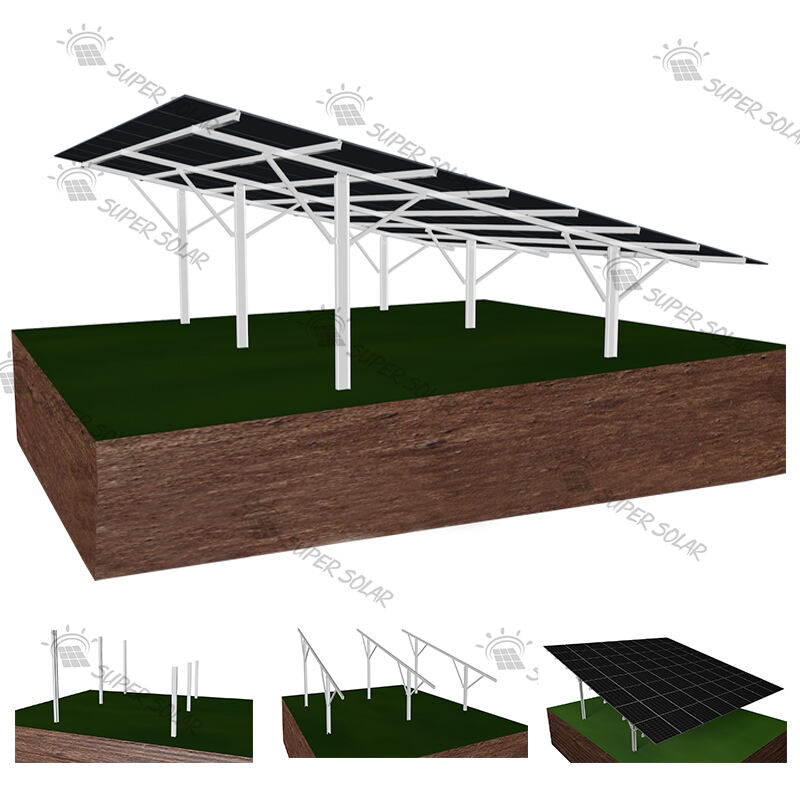

Carbon steel ground mounted solar structure systems demonstrate exceptional versatility through innovative design solutions that accommodate diverse site conditions, panel technologies, and future expansion requirements while maintaining optimal performance characteristics. The modular architecture enables customization for specific project parameters including panel dimensions, tilt angles, row spacing, and tracking configurations without requiring extensive engineering modifications or specialized components. Carbon steel ground mounted solar structure designs seamlessly integrate with various foundation types ranging from driven piles in stable soils to ballasted systems for sensitive environments where ground penetration must be minimized. The structural framework accommodates multiple panel orientations including fixed-tilt, single-axis tracking, and dual-axis tracking configurations, allowing project developers to optimize energy generation based on site-specific solar resources and economic considerations. Advanced connection systems enable rapid assembly and disassembly for temporary installations or system relocation scenarios, providing valuable flexibility for evolving land use requirements or lease agreements. The inherent strength and stiffness properties of carbon steel support larger panel arrays and higher mounting heights compared to alternative materials, enabling increased power density and improved land utilization efficiency. Carbon steel ground mounted solar structure systems adapt to challenging topographical conditions including sloped terrain, irregular boundaries, and areas with existing infrastructure constraints through engineered solutions and custom configurations. The compatibility with emerging panel technologies including bifacial modules, flexible panels, and concentrated photovoltaic systems ensures long-term relevance and investment protection as solar technology continues advancing. Future expansion capabilities allow incremental capacity additions without disrupting existing installations, supporting phased development strategies and growing energy demands. The standardized interface specifications facilitate integration with monitoring systems, cleaning equipment, and maintenance platforms, creating comprehensive solar installation solutions. Environmental compliance features include wildlife-friendly designs, vegetation management considerations, and end-of-life recyclability that support sustainable development objectives and regulatory requirements across diverse jurisdictions and ecological settings.