solar panel tilt mounting brackets factories

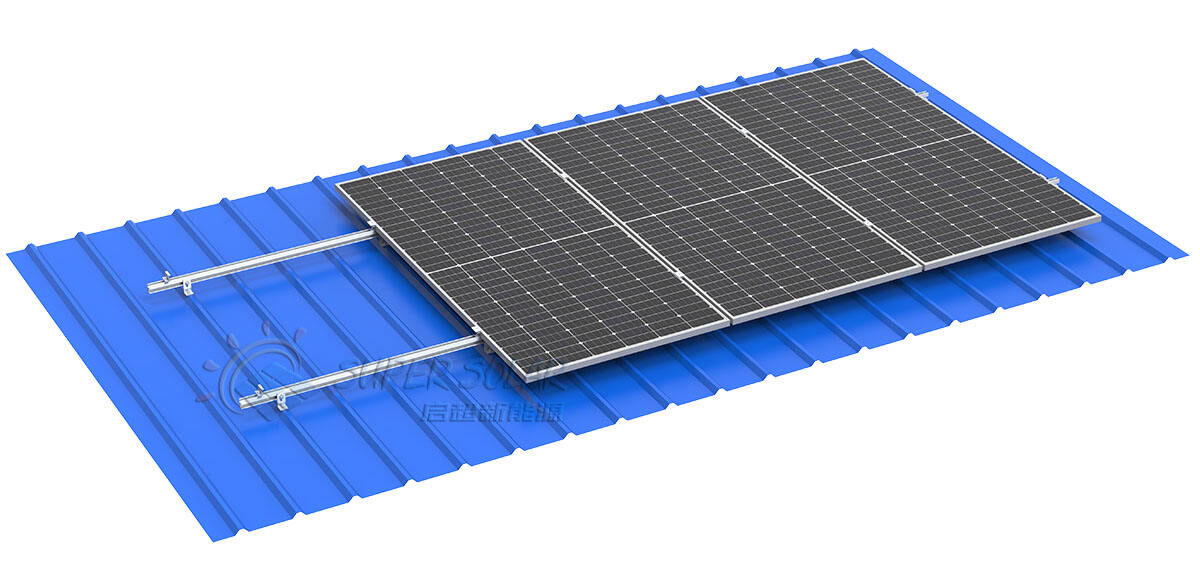

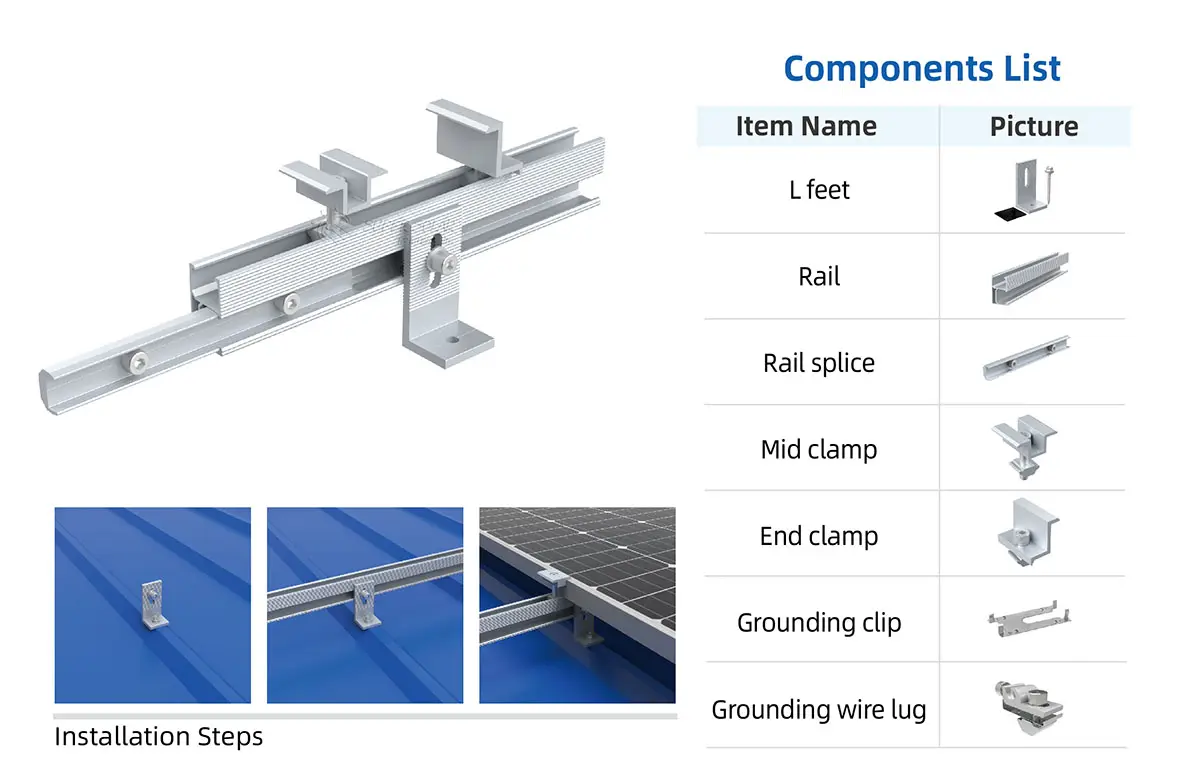

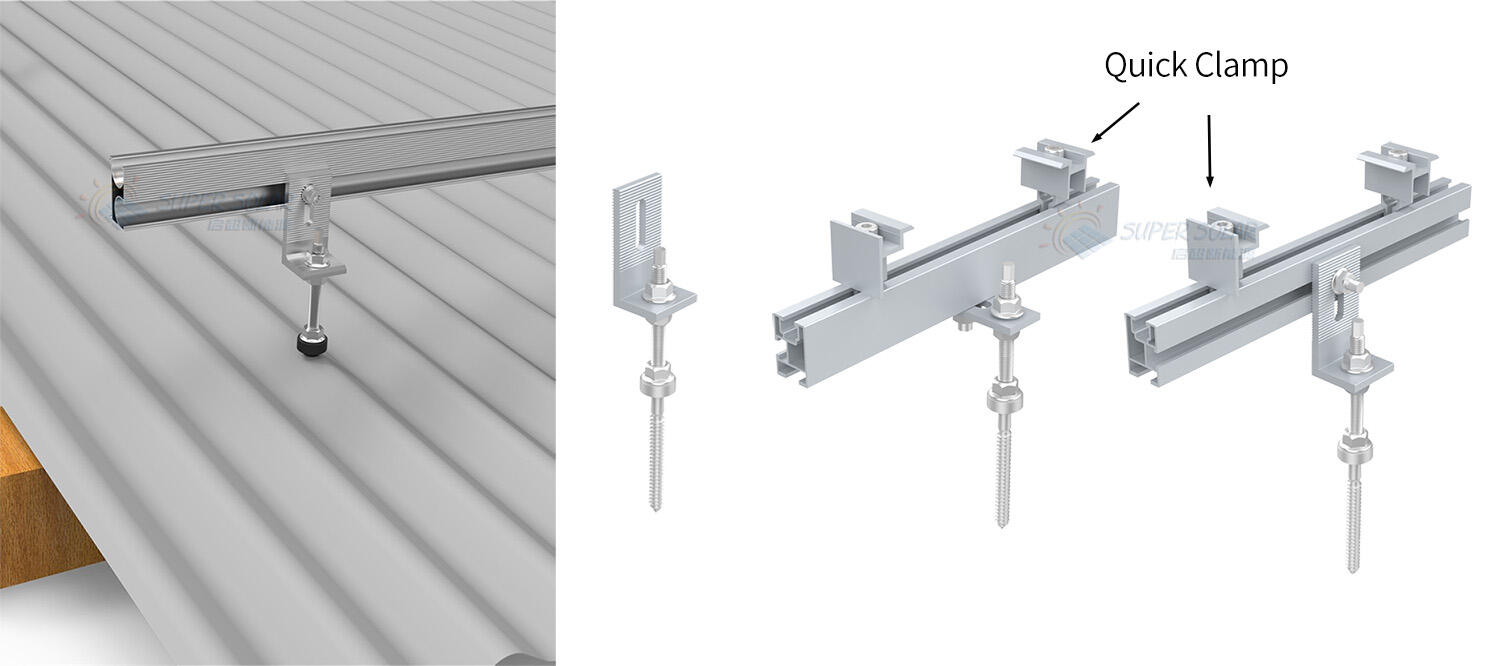

Solar panel tilt mounting brackets factories represent specialized manufacturing facilities that produce essential components for photovoltaic installations worldwide. These industrial establishments focus on creating robust, adjustable mounting systems designed to optimize solar panel positioning for maximum energy generation. The primary function of solar panel tilt mounting brackets factories involves engineering and manufacturing brackets that allow precise angular adjustment of solar arrays, ensuring optimal exposure to sunlight throughout different seasons and geographical locations. These facilities employ advanced manufacturing processes including precision metal cutting, welding, galvanizing, and quality control testing to produce durable mounting solutions. The technological features of modern solar panel tilt mounting brackets factories incorporate computer-aided design systems, automated production lines, and rigorous testing protocols to ensure product reliability and performance standards. Manufacturing processes typically utilize high-grade aluminum alloys and stainless steel materials that provide excellent corrosion resistance and structural integrity. Quality control departments within these factories implement comprehensive testing procedures including load bearing tests, weather resistance evaluations, and dimensional accuracy verification. The applications of products from solar panel tilt mounting brackets factories span residential rooftop installations, commercial building projects, utility-scale solar farms, and specialized mounting requirements for unique architectural configurations. These factories serve diverse markets including solar installation companies, electrical contractors, renewable energy developers, and direct consumers seeking reliable mounting solutions. Advanced solar panel tilt mounting brackets factories also focus on developing innovative features such as tool-free installation mechanisms, universal compatibility designs, and enhanced adjustment ranges to accommodate various panel sizes and installation requirements. The manufacturing capabilities of these facilities often include custom fabrication services, bulk production orders, and specialized coating applications to meet specific environmental conditions and customer specifications.