solar tracker factory

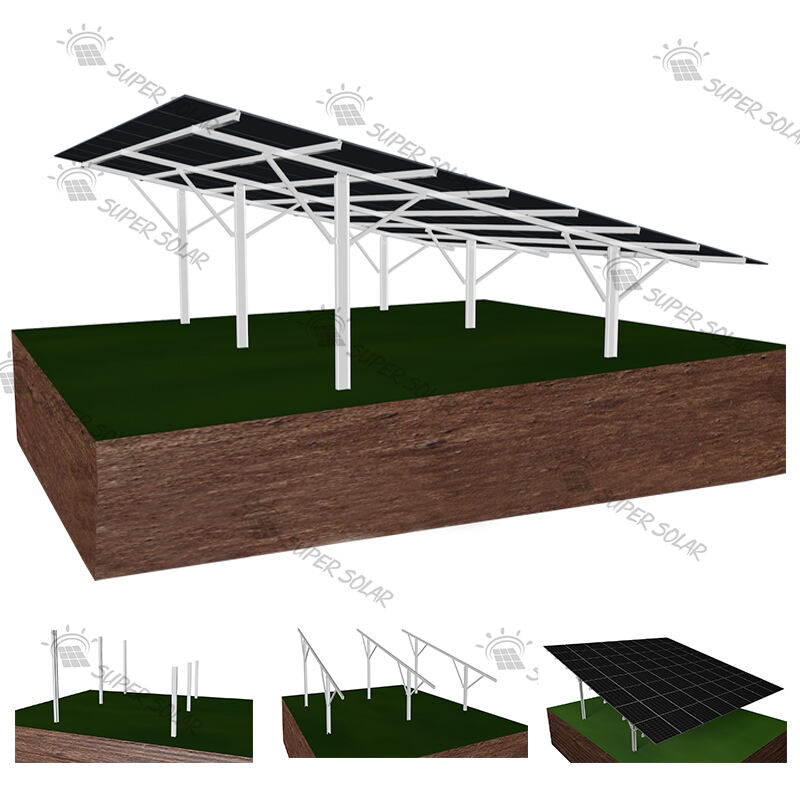

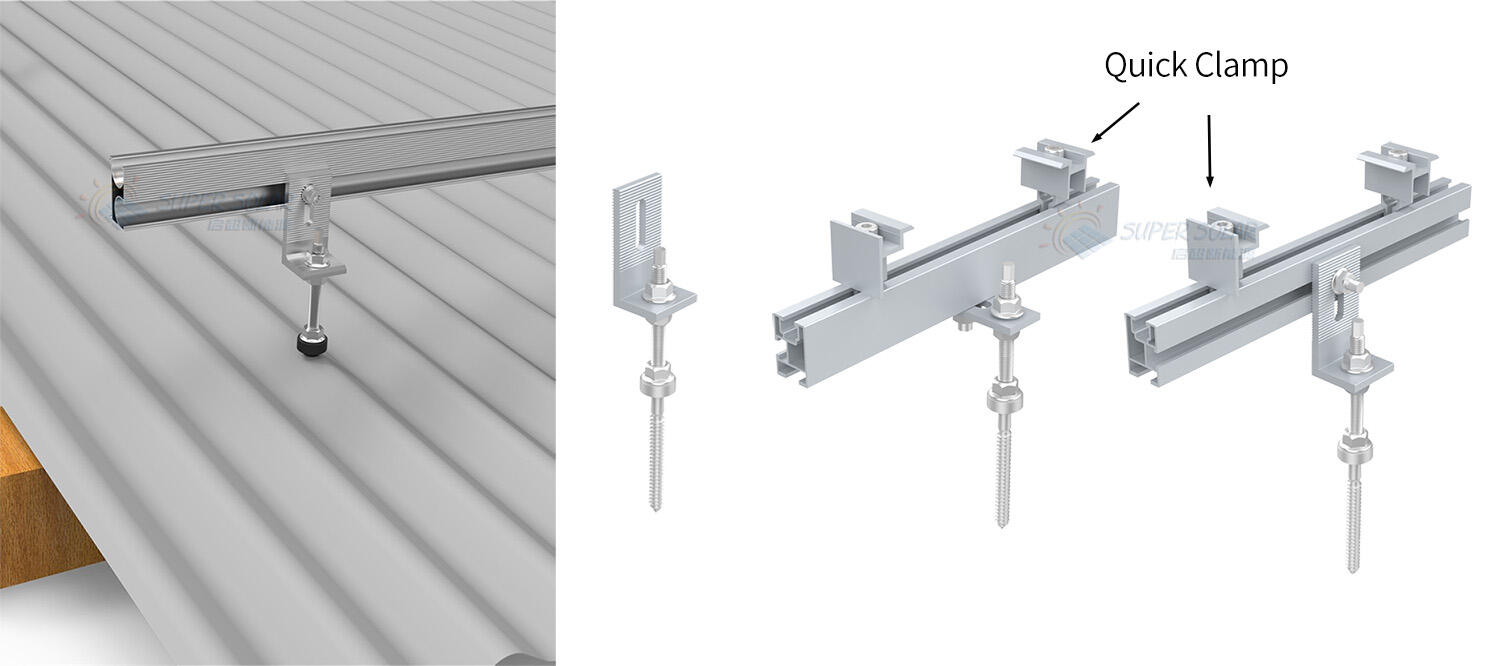

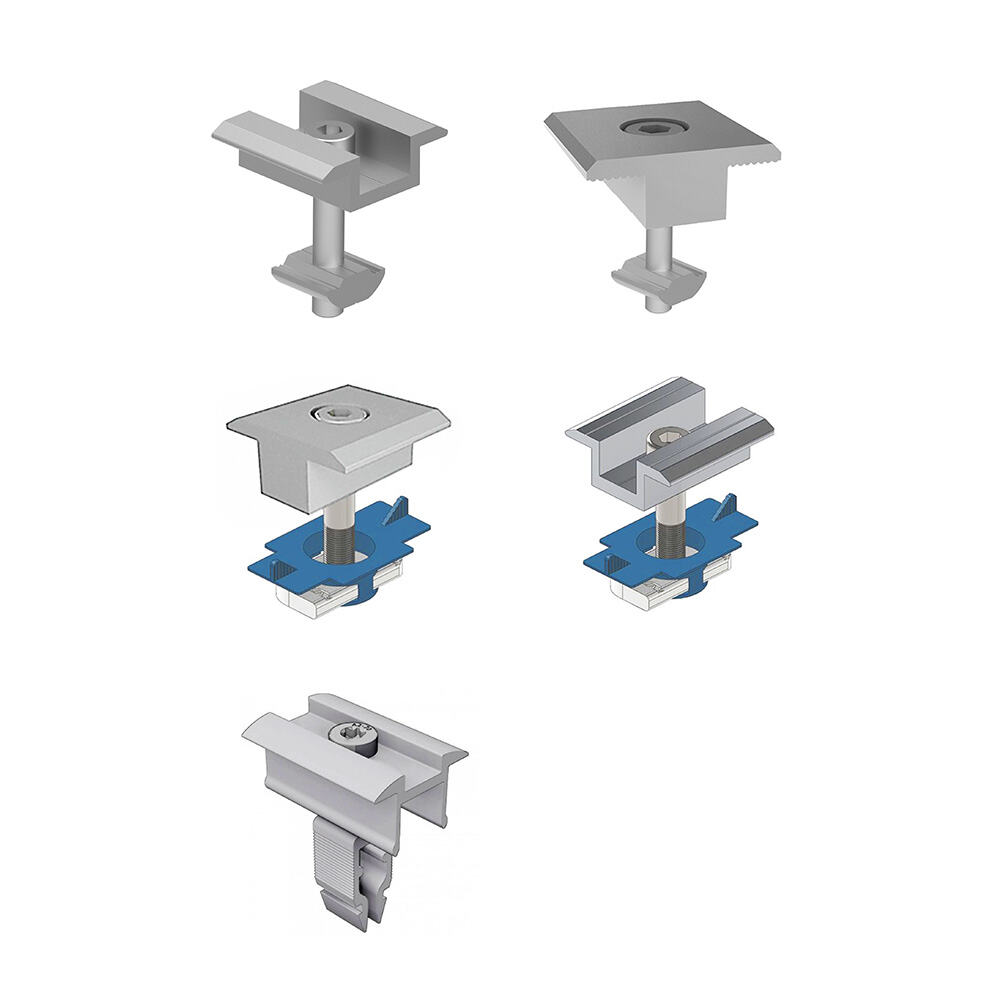

A solar tracker factory represents the pinnacle of renewable energy manufacturing excellence, serving as a specialized production facility dedicated to creating advanced photovoltaic tracking systems. These sophisticated manufacturing centers focus on producing solar tracking devices that automatically orient solar panels toward the sun throughout the day, maximizing energy capture and improving overall system efficiency. The solar tracker factory incorporates cutting-edge production technologies, precision engineering capabilities, and rigorous quality control processes to deliver superior tracking solutions for commercial, utility-scale, and residential solar installations worldwide. Modern solar tracker factory operations utilize automated assembly lines, computer-controlled manufacturing processes, and advanced materials science to produce durable, reliable tracking systems. The facility typically houses multiple production departments including mechanical component manufacturing, electronic control system assembly, software development laboratories, and comprehensive testing centers. Each solar tracker factory maintains strict quality standards through ISO certification processes, ensuring every product meets international safety and performance requirements. The manufacturing process within a solar tracker factory involves precision machining of steel components, assembly of drive mechanisms, integration of smart control systems, and thorough performance validation testing. Advanced solar tracker factory facilities employ lean manufacturing principles, sustainable production practices, and continuous improvement methodologies to optimize efficiency while minimizing environmental impact. These production centers serve global markets by manufacturing various tracker types including single-axis horizontal, dual-axis systems, and specialized tracking solutions for different geographical conditions and installation requirements.