solar mounting system for tin roof

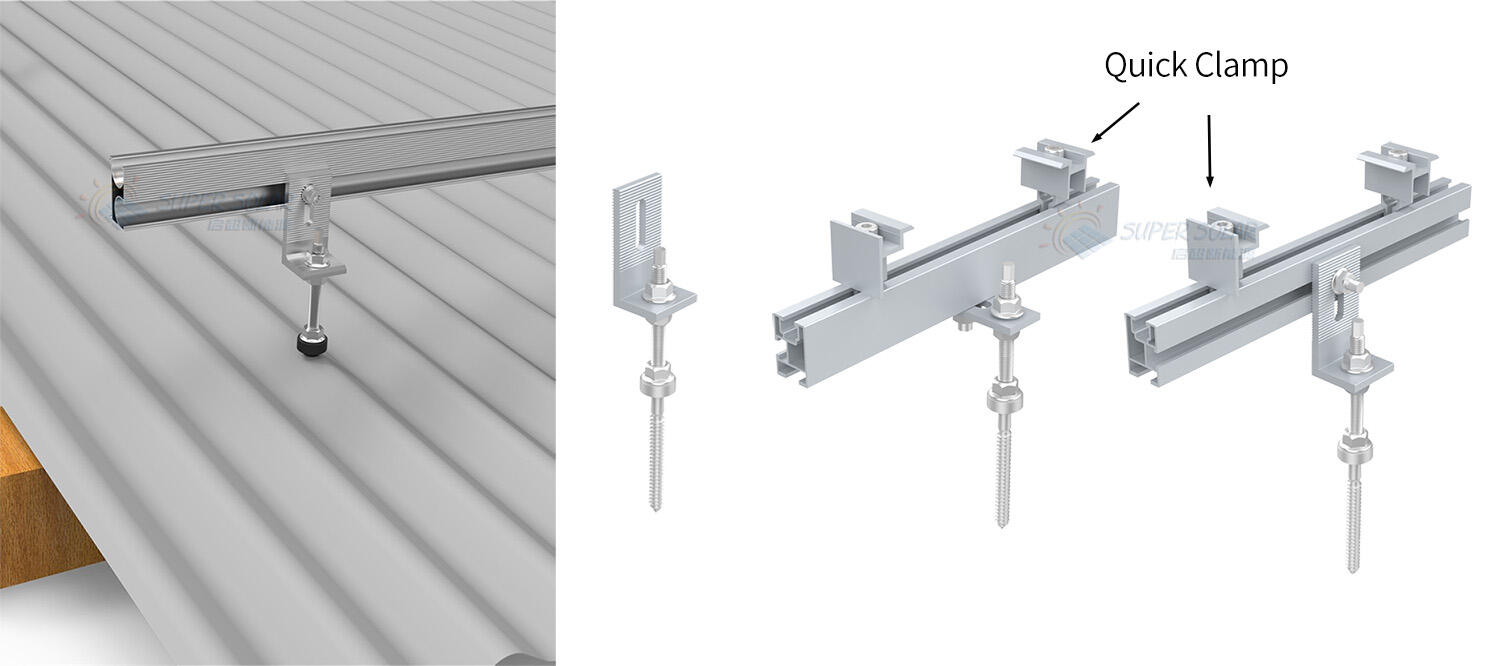

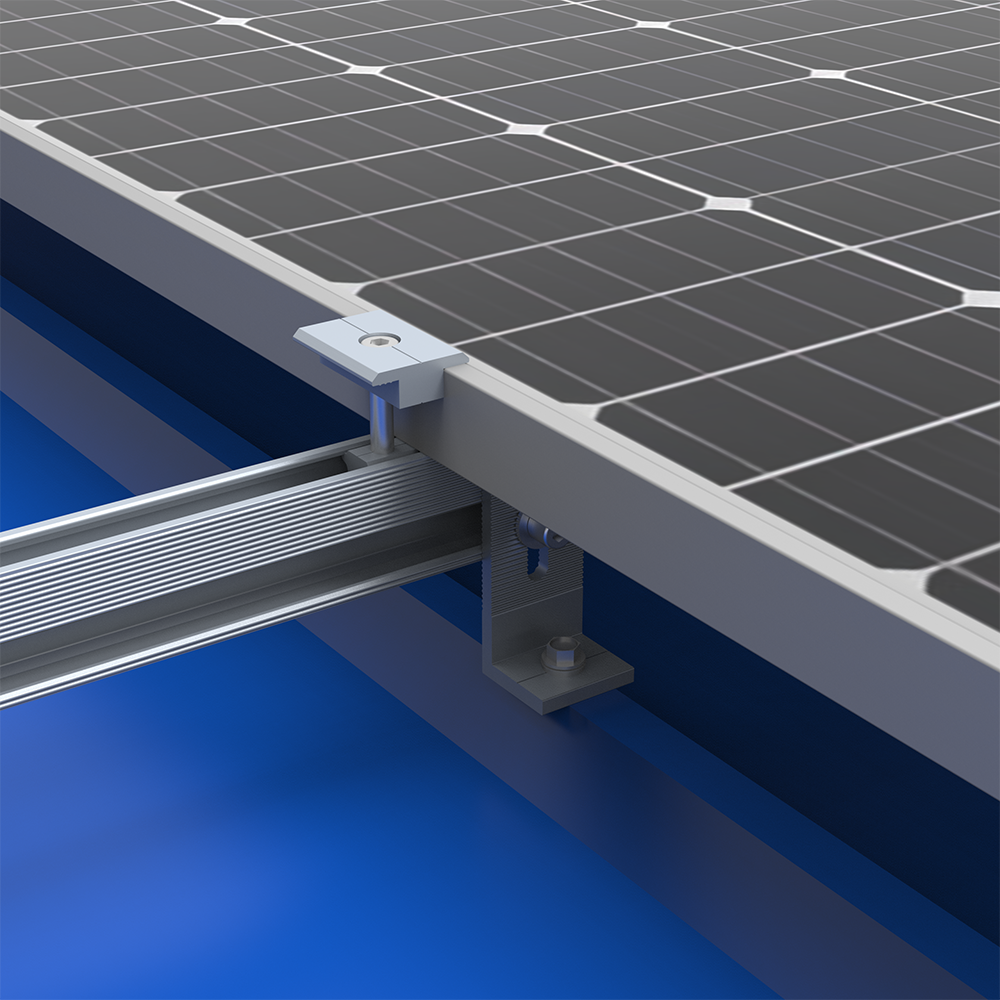

A solar mounting system for tin roof represents a specialized installation solution designed to securely attach solar panels to corrugated metal roofing surfaces. This mounting system serves as the critical interface between photovoltaic panels and the structural integrity of tin roofs, ensuring optimal energy generation while maintaining building safety standards. The primary function of this solar mounting system for tin roof involves creating a stable, weatherproof connection that accommodates the unique characteristics of metal roofing materials. These systems typically incorporate advanced clamping mechanisms that grip the raised ridges of corrugated tin without penetrating the roof surface, eliminating potential leak points. The technological features of modern solar mounting systems for tin roof include corrosion-resistant aluminum alloy construction, adjustable tilt angles for maximum solar exposure, and integrated grounding capabilities for electrical safety. Advanced rail systems distribute panel weight evenly across multiple roof ribs, preventing localized stress concentrations that could damage the roofing material. Many systems incorporate pre-assembled components that streamline installation processes, reducing labor costs and installation time. The applications of solar mounting systems for tin roof span residential, commercial, and industrial sectors where metal roofing is prevalent. Agricultural buildings, warehouses, manufacturing facilities, and rural homes frequently utilize tin roofing, making these mounting systems essential for solar adoption in these markets. The versatility of these systems allows adaptation to various tin roof profiles, including standing seam, corrugated, and trapezoidal configurations. Weather resistance features ensure long-term performance in diverse climatic conditions, from extreme heat to heavy snow loads. The modular design facilitates future system expansion, allowing property owners to increase solar capacity as energy needs grow or budgets allow.