aluminum solar panel mounting systems

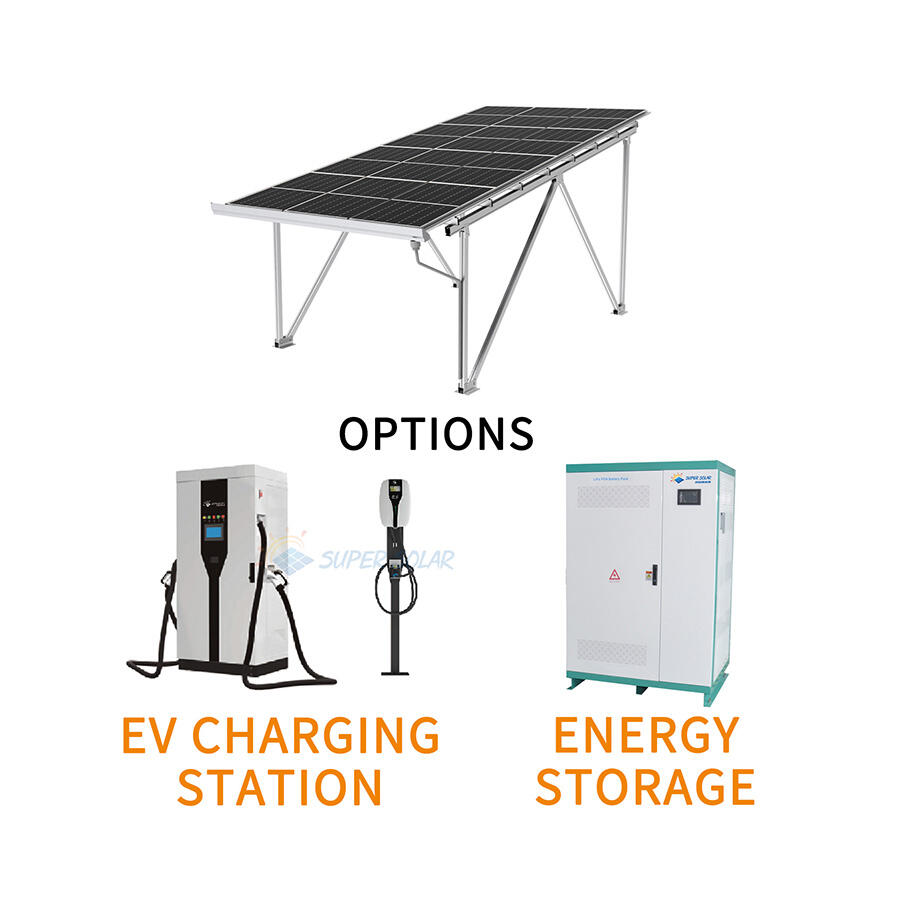

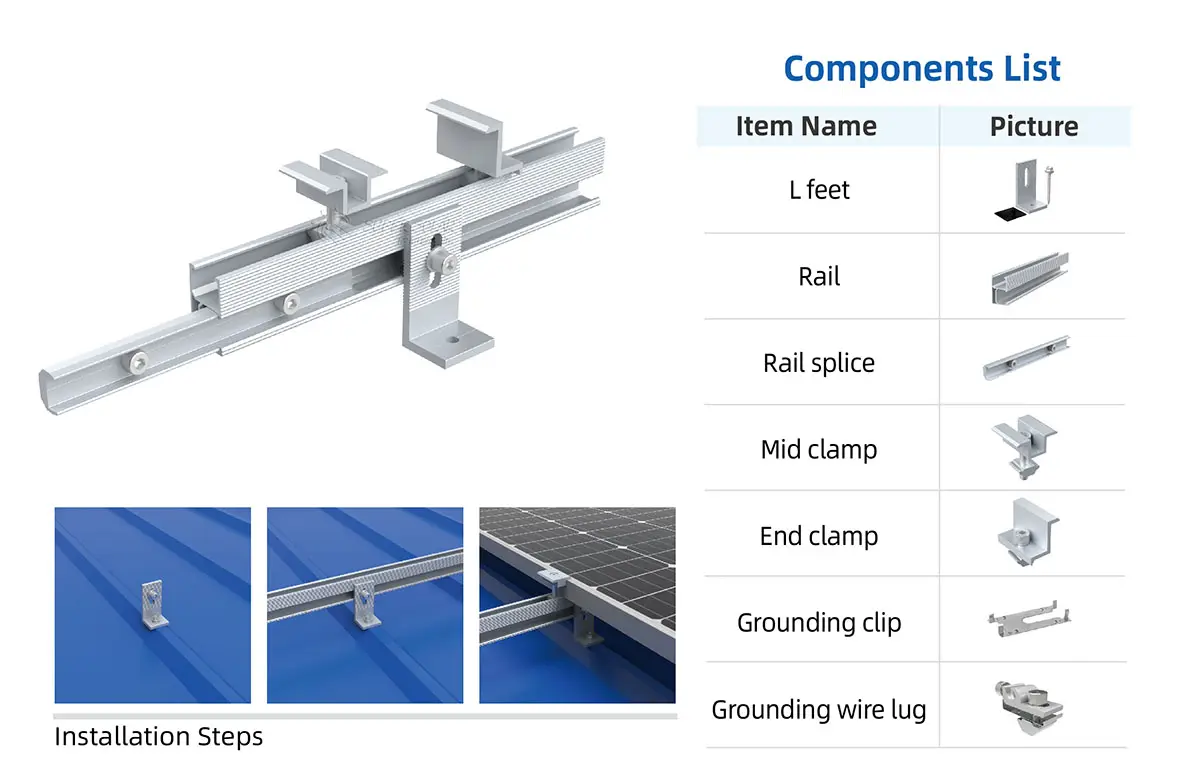

Aluminum solar panel mounting systems represent the backbone of modern photovoltaic installations, providing essential structural support that ensures optimal energy generation for decades. These sophisticated frameworks are engineered to secure solar panels in precise positions while withstanding environmental challenges including wind loads, snow accumulation, and thermal expansion cycles. The primary function of aluminum solar panel mounting systems extends beyond simple attachment, encompassing critical roles in electrical grounding, thermal management, and maintenance accessibility. These systems utilize advanced aluminum alloy compositions that deliver exceptional strength-to-weight ratios, making installation processes more efficient while maintaining structural integrity under demanding conditions. The technological features of aluminum solar panel mounting systems include precision-engineered rail profiles, adjustable clamps, and modular components that accommodate various panel sizes and installation requirements. Modern systems incorporate innovative design elements such as pre-assembled hardware, snap-fit connections, and integrated drainage channels that streamline installation procedures. The grounding mechanisms within aluminum solar panel mounting systems ensure electrical safety through continuous bonding pathways that meet stringent electrical codes and standards. Applications for aluminum solar panel mounting systems span residential rooftops, commercial buildings, utility-scale ground installations, and specialized environments including carports and canopies. These versatile systems adapt to diverse roof materials including asphalt shingles, metal roofing, tile surfaces, and membrane systems through specialized attachment methods. The corrosion-resistant properties of aluminum enable aluminum solar panel mounting systems to perform reliably in coastal environments, industrial areas, and regions with extreme weather patterns. Advanced engineering ensures these systems maintain panel alignment and structural performance throughout 25-year warranty periods and beyond, supporting long-term energy production goals while minimizing maintenance requirements.