china metal roof solar brackets

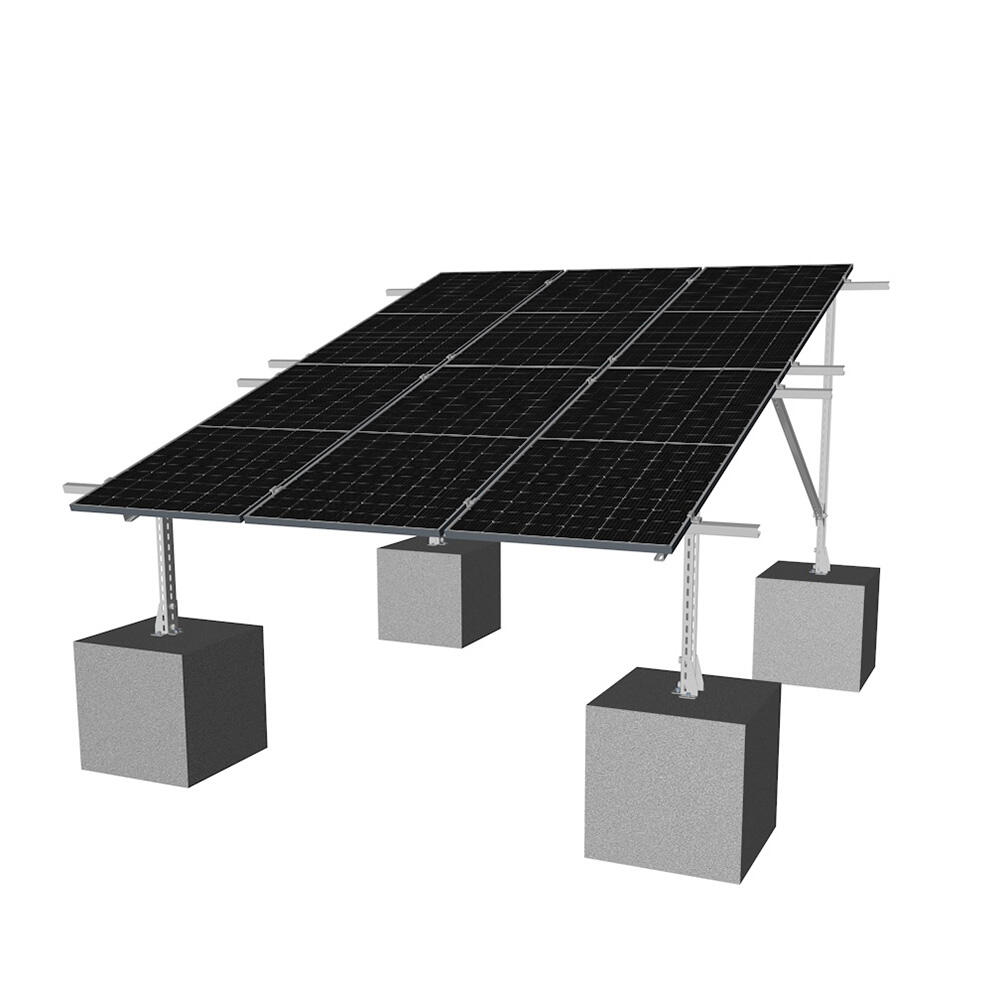

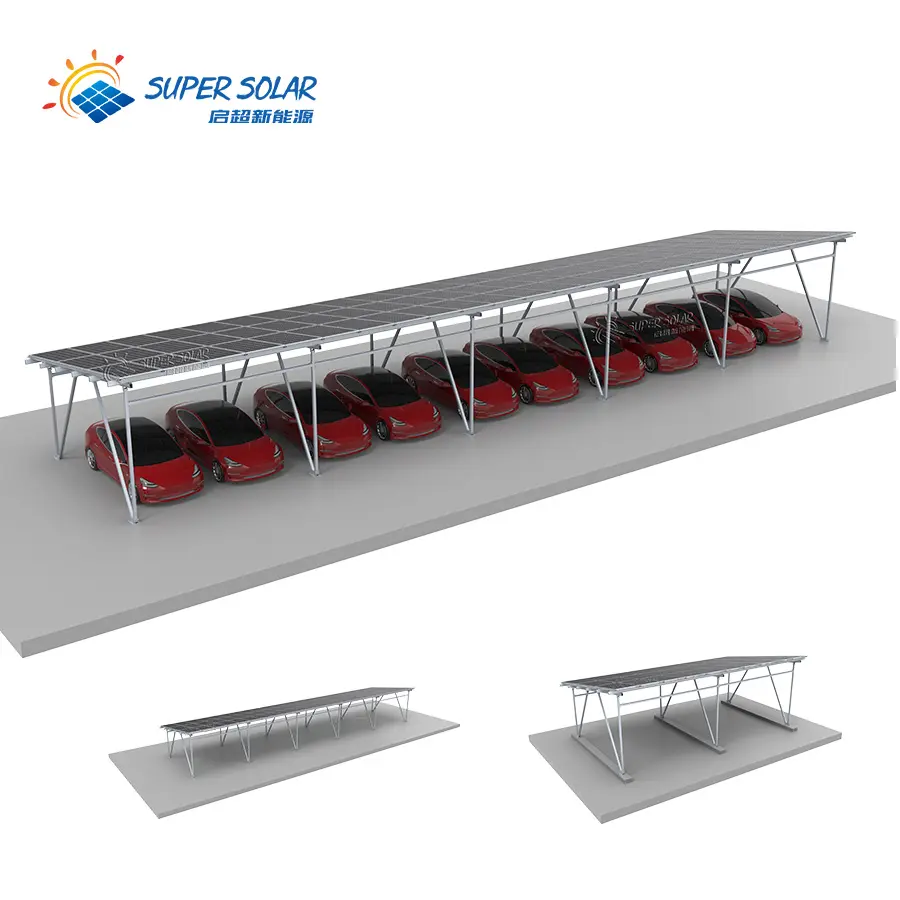

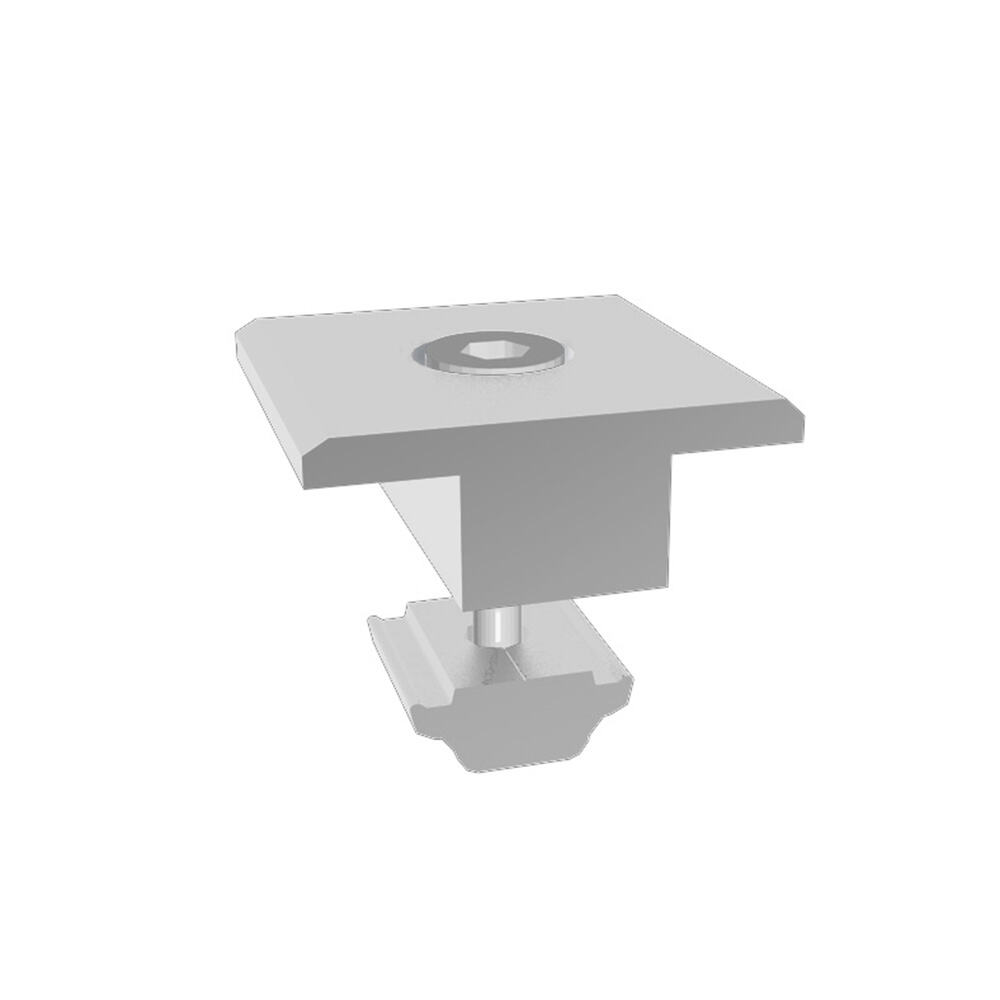

China metal roof solar brackets represent a revolutionary mounting solution designed specifically for installing solar panels on various metal roofing systems. These innovative brackets serve as the critical foundation that secures photovoltaic panels to metal roofs, ensuring optimal stability and performance throughout the solar installation's lifespan. The primary function of china metal roof solar brackets involves creating a secure attachment point between solar panels and metal roofing substrates while maintaining the roof's structural integrity and waterproofing properties. These mounting systems accommodate different metal roof profiles, including standing seam, corrugated, and trapezoidal configurations, making them versatile solutions for diverse architectural applications. The technological features of china metal roof solar brackets incorporate advanced engineering principles that address wind uplift resistance, thermal expansion management, and seismic stability requirements. Manufacturing processes utilize high-grade aluminum alloys and stainless steel components that resist corrosion, ensuring long-term durability in various environmental conditions. The brackets feature precision-engineered clamps and fastening mechanisms that distribute loads evenly across the roof structure, preventing stress concentration points that could compromise roof integrity. Advanced powder coating and anodization treatments provide additional protection against weathering and UV degradation. Applications for china metal roof solar brackets span residential, commercial, and industrial sectors where metal roofing systems are prevalent. Residential installations benefit from the clean aesthetic integration these brackets provide, while commercial and industrial applications leverage their ability to handle larger solar arrays with minimal roof penetration. The brackets accommodate various panel orientations and tilt angles, enabling optimal solar exposure regardless of roof geometry. Installation procedures for china metal roof solar brackets emphasize efficiency and reliability, with pre-assembled components that reduce field labor requirements and minimize installation errors. Quality control standards ensure consistent performance across different environmental conditions, making these brackets suitable for global deployment in diverse climatic regions.