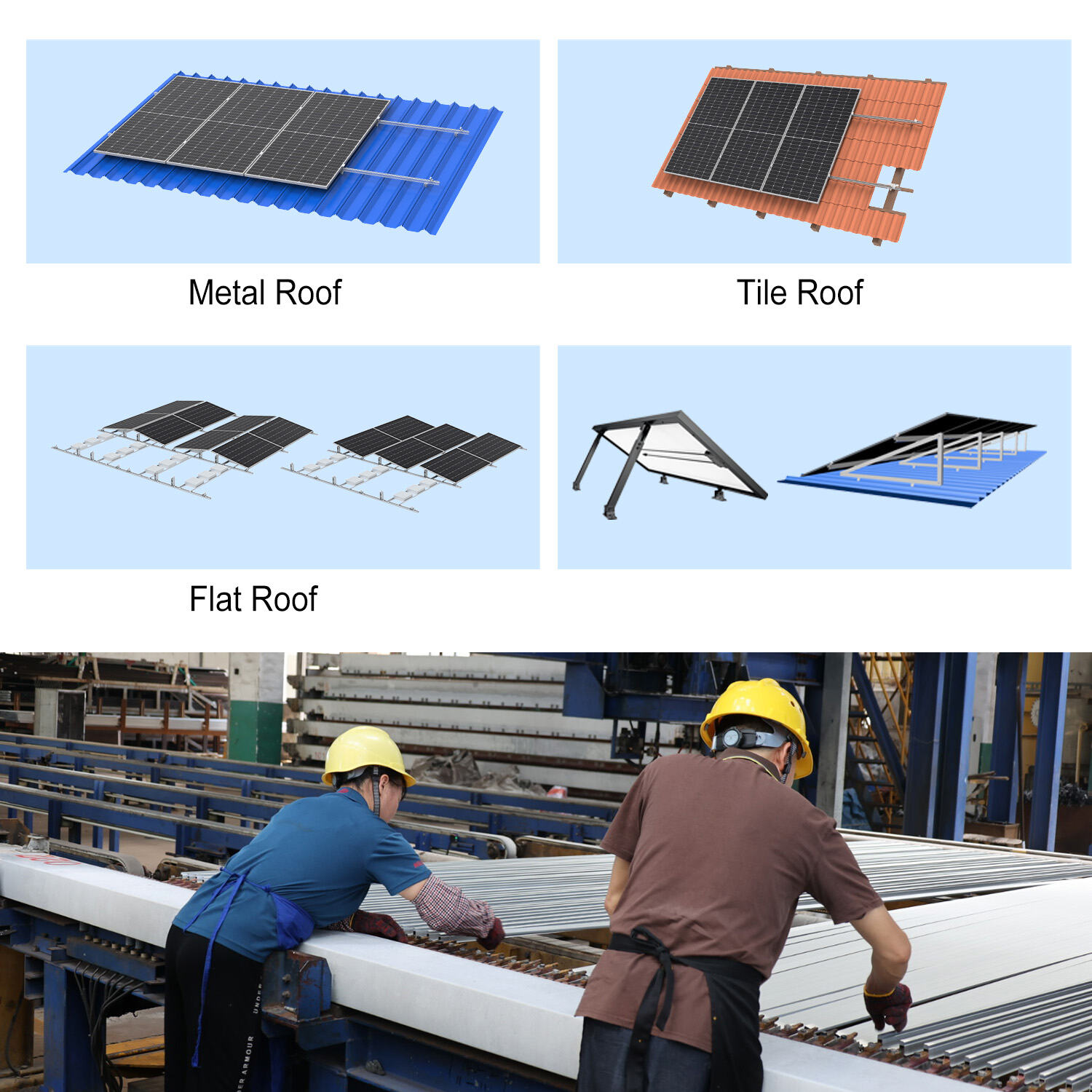

metal roof solar brackets in stock

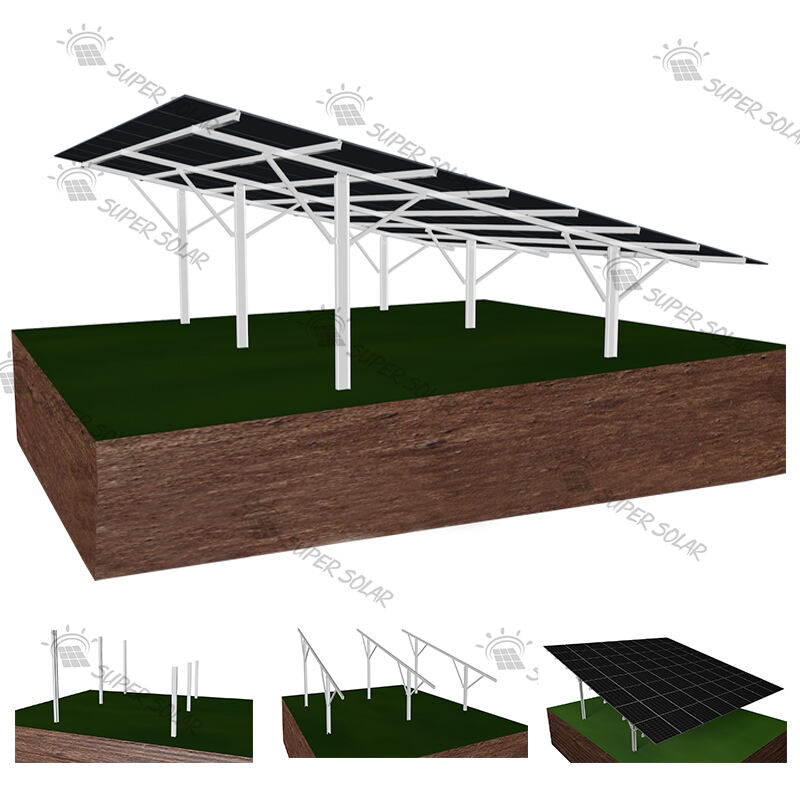

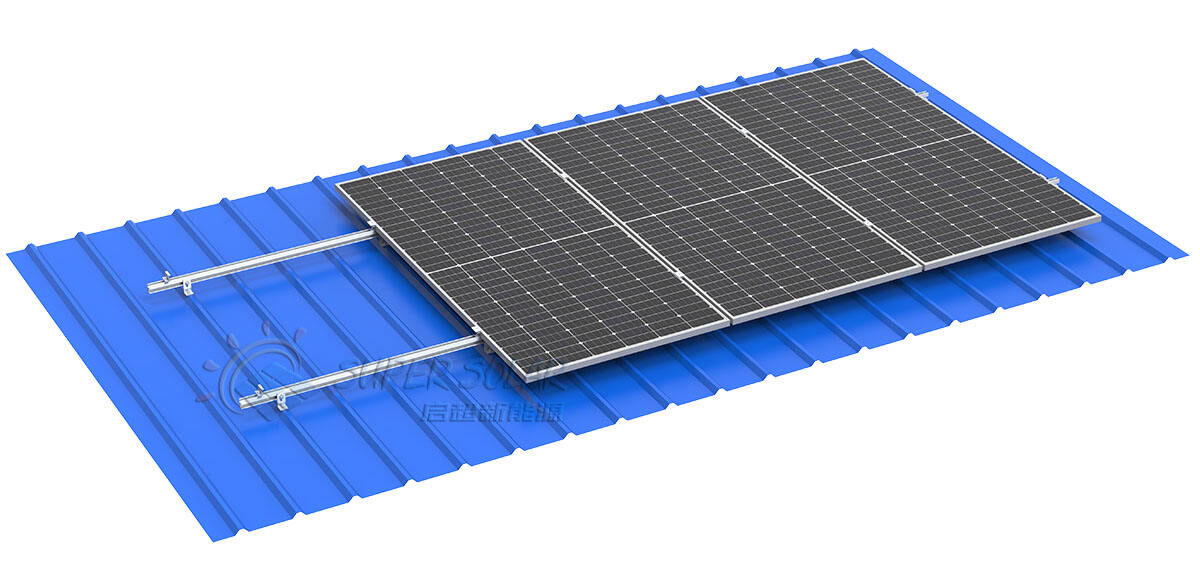

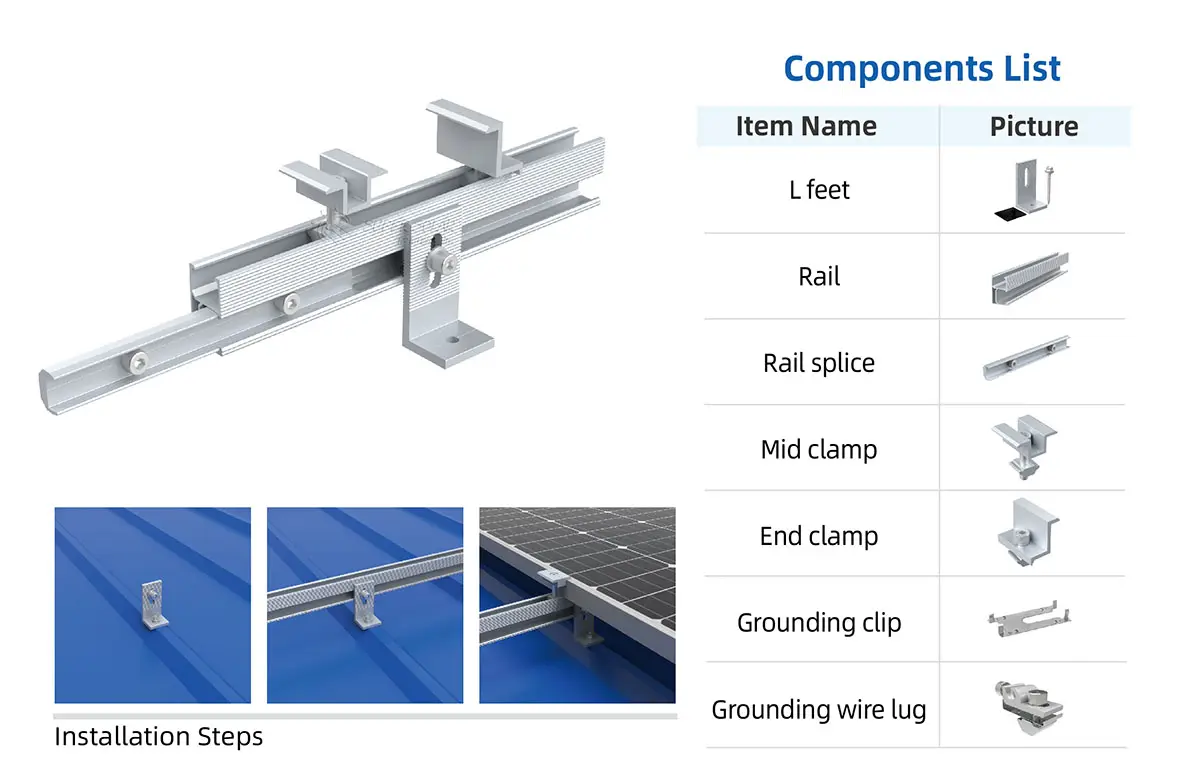

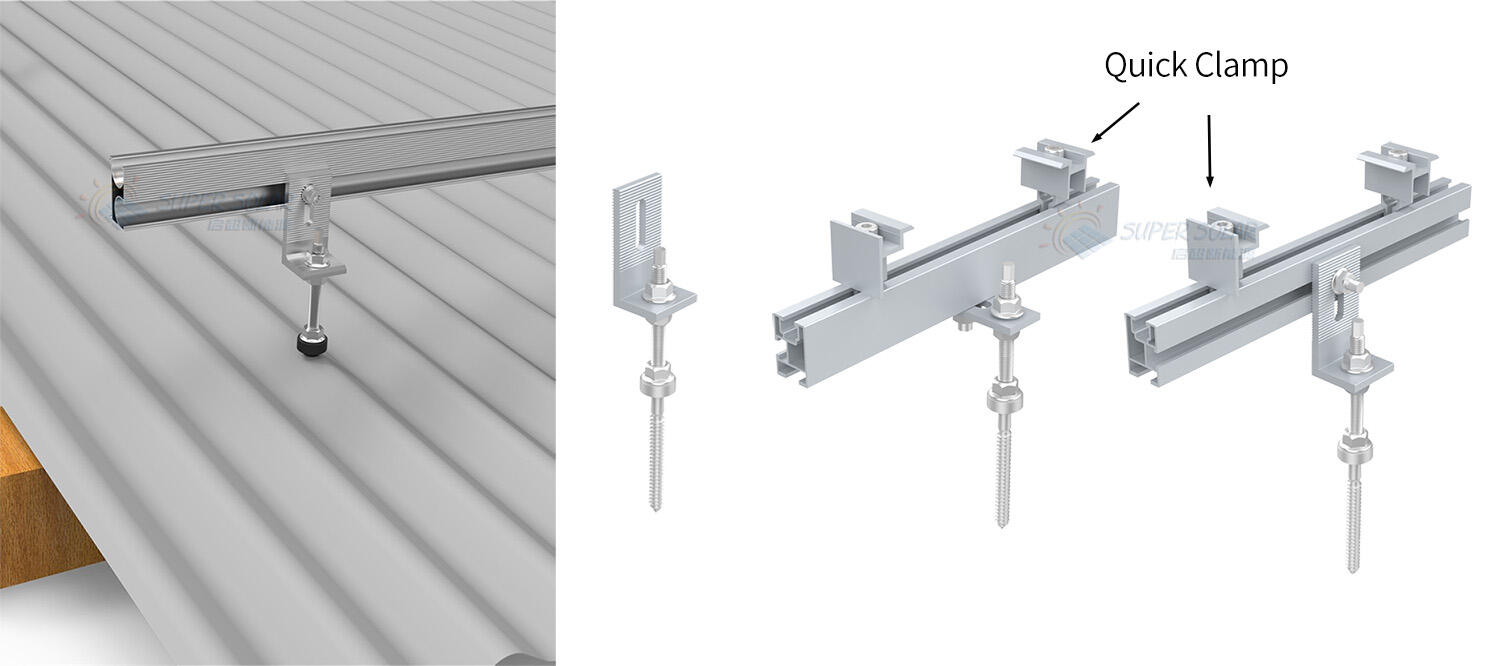

Metal roof solar brackets in stock represent a comprehensive mounting solution designed specifically for installing solar panels on metal roofing systems. These specialized hardware components serve as the critical interface between photovoltaic modules and metal roof surfaces, ensuring secure attachment while maintaining the structural integrity of both the roofing system and solar installation. The primary function of metal roof solar brackets in stock involves creating a stable, weather-resistant mounting platform that accommodates various metal roofing profiles including standing seam, corrugated, and ribbed configurations. These brackets utilize advanced engineering principles to distribute load forces evenly across the roof structure, preventing localized stress concentrations that could compromise roof performance. Technological features of metal roof solar brackets in stock include corrosion-resistant materials such as aluminum alloy or stainless steel construction, precision-engineered clamping mechanisms that grip metal roof seams without penetration, and adjustable components that accommodate different panel orientations and roof angles. The brackets incorporate weather sealing technologies including EPDM rubber gaskets and waterproof membranes that prevent moisture infiltration at attachment points. Applications for metal roof solar brackets in stock span residential, commercial, and industrial installations where metal roofing systems are present. These mounting solutions are particularly valuable for warehouse facilities, manufacturing plants, agricultural buildings, and modern residential structures featuring metal roofing materials. The brackets enable solar installations on both new construction projects and retrofit applications, providing property owners with renewable energy options while preserving existing roofing investments. Professional installers rely on metal roof solar brackets in stock for their versatility in accommodating different metal roof geometries and their ability to maintain manufacturer warranties on both roofing and solar components through non-penetrating attachment methods.